Elastic materials return to their original shape after being stretched or compressed, demonstrating resilience and flexibility crucial in various applications. Understanding elasticity helps optimize design in industries like automotive, construction, and healthcare, where durability and performance are essential. Discover how mastering elastic properties can enhance your projects by reading the full article.

Table of Comparison

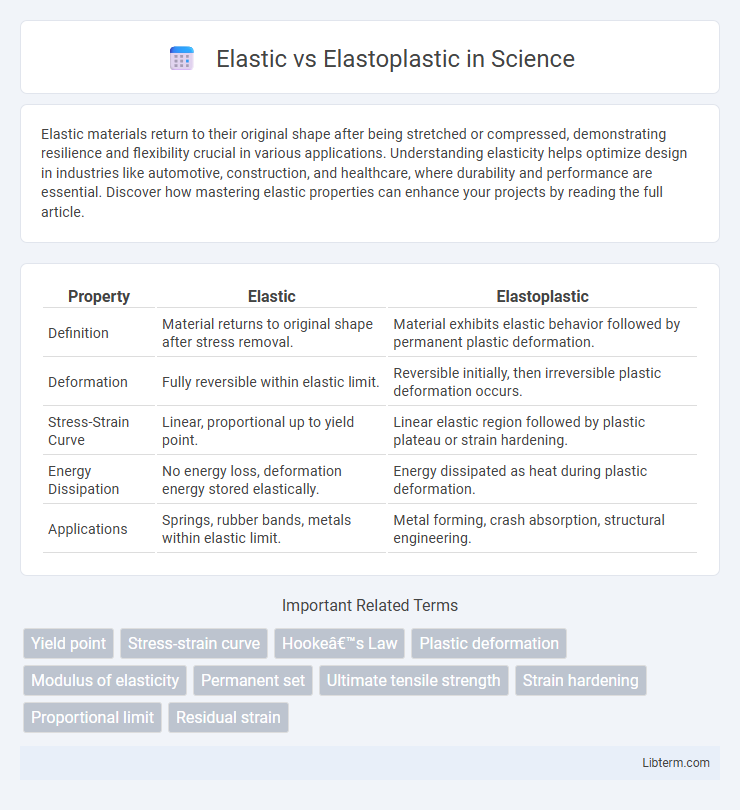

| Property | Elastic | Elastoplastic |

|---|---|---|

| Definition | Material returns to original shape after stress removal. | Material exhibits elastic behavior followed by permanent plastic deformation. |

| Deformation | Fully reversible within elastic limit. | Reversible initially, then irreversible plastic deformation occurs. |

| Stress-Strain Curve | Linear, proportional up to yield point. | Linear elastic region followed by plastic plateau or strain hardening. |

| Energy Dissipation | No energy loss, deformation energy stored elastically. | Energy dissipated as heat during plastic deformation. |

| Applications | Springs, rubber bands, metals within elastic limit. | Metal forming, crash absorption, structural engineering. |

Introduction to Elastic and Elastoplastic Behavior

Elastic behavior describes materials that return to their original shape immediately after removing applied stress, characterized by a linear stress-strain relationship governed by Hooke's Law. Elastoplastic behavior combines elastic deformation with plastic deformation, where permanent strain occurs once the material surpasses its yield strength, causing irreversible changes. Understanding the distinction between elastic and elastoplastic responses is essential for predicting material performance under various loading conditions in engineering and structural applications.

Fundamental Concepts: Elasticity vs. Elastoplasticity

Elasticity refers to the ability of a material to return to its original shape after the removal of applied stress, characterized by a linear stress-strain relationship within the elastic limit defined by Hooke's Law. Elastoplasticity combines elastic behavior with plastic deformation, where the material undergoes permanent strain beyond the yield point, exhibiting both recoverable and irreversible deformations. Fundamental differences include elasticity's reversible deformation and elastoplasticity's mixture of reversible elastic and irreversible plastic strain governed by yield criteria such as the von Mises or Tresca conditions.

Mechanical Response under Load: A Comparative Overview

Elastic materials exhibit a linear mechanical response under load, characterized by reversible deformation where stress is directly proportional to strain, following Hooke's Law. Elastoplastic materials combine elastic behavior with plastic deformation, showing an initial linear elastic region followed by irreversible strain beyond the yield point, leading to permanent shape changes. This distinction impacts structural design, where elasticity ensures recovery after load removal, whereas elastoplasticity accommodates permanent deformations without catastrophic failure.

Stress-Strain Curves: Key Differences

Elastic materials exhibit a linear stress-strain curve where deformation is fully reversible upon unloading, adhering to Hooke's Law up to the yield point. Elastoplastic materials show a nonlinear curve, displaying initial elastic behavior followed by plastic deformation where permanent strain occurs beyond the yield stress. The key difference lies in the irreversible deformation region of elastoplastic curves, contrasting with the purely recoverable strain in elastic curves.

Material Examples: Elastic vs. Elastoplastic Properties

Rubber exemplifies elastic materials, returning to its original shape after deformation due to reversible stress-strain behavior, while mild steel demonstrates elastoplastic properties by undergoing permanent deformation beyond its yield point. Elastic materials such as nylon and glass maintain linear stress-strain responses within their elastic limits, whereas elastoplastic materials like aluminum and copper exhibit both elastic recovery and plastic flow depending on the applied load. The distinction between elastic and elastoplastic properties is crucial in structural engineering, influencing material selection for applications requiring flexibility without permanent deformation versus those needing ductility and energy absorption.

Mathematical Modeling Techniques

Elastic mathematical modeling relies on linear equations representing stress-strain relationships assuming material returns to its original shape after deformation, typically using Hooke's Law. Elastoplastic modeling incorporates both elastic and plastic behavior, employing nonlinear constitutive models such as bilinear or multi-linear kinematic hardening rules to capture irreversible deformations. Finite element methods often implement elastoplastic models using yield criteria like von Mises or Tresca combined with flow rules and hardening laws to simulate material response under complex loading conditions.

Applications in Engineering and Design

Elastic materials return to their original shape after stress is removed, making them ideal for applications requiring reversible deformation like springs, seals, and structural components subjected to fluctuating loads. Elastoplastic materials exhibit permanent deformation after exceeding the elastic limit, commonly used in metal forming, crash barriers, and safety devices that absorb energy through plastic deformation. Engineering design leverages elasticity for durability and repeated use, while elastoplasticity is critical for energy dissipation, shaping processes, and impact resistance in components such as automotive chassis and aerospace structures.

Factors Influencing Elastic and Elastoplastic Behavior

Material behavior under stress is influenced by factors such as temperature, strain rate, and microstructural composition, which affect whether a material exhibits elastic or elastoplastic responses. High temperatures and increased strain rates tend to promote elastoplastic deformation by enabling dislocation movement and permanent shape changes. The presence of defects, grain boundaries, and alloying elements also plays a critical role in determining the threshold between reversible elastic deformation and irreversible plastic flow.

Advantages and Limitations of Elastic and Elastoplastic Materials

Elastic materials exhibit the advantage of returning to their original shape after stress removal, enabling predictable performance and durability in applications requiring repeated loading cycles. Limitations include their inability to undergo permanent deformation, which restricts energy absorption and adaptation to plastic deformation under excessive stress. Elastoplastic materials combine elasticity with permanent deformation capabilities, allowing energy dissipation and shape change without fracture, but they may suffer from residual strain and reduced dimensional stability over time.

Conclusion: Choosing the Right Material Model

Elastic models are ideal for materials that return to their original shape after deformation, providing accurate predictions in scenarios with small strains and reversible loading conditions. Elastoplastic models better represent materials undergoing permanent deformation, capturing yield behavior and post-yield strain accurately, which is crucial in metal forming, crash simulations, and structural failure analysis. Selecting between elastic and elastoplastic models depends on the application's demands for accuracy in predicting either reversible or irreversible material behavior under applied loads.

Elastic Infographic

libterm.com

libterm.com