Viscoelastic materials exhibit both viscous and elastic characteristics when undergoing deformation, offering unique mechanical behavior essential in applications like prosthetics, automotive components, and cushioning systems. Their ability to absorb energy and dissipate stress improves durability and comfort, making them valuable in various industries. Explore the rest of the article to understand how viscoelasticity influences material performance and your design choices.

Table of Comparison

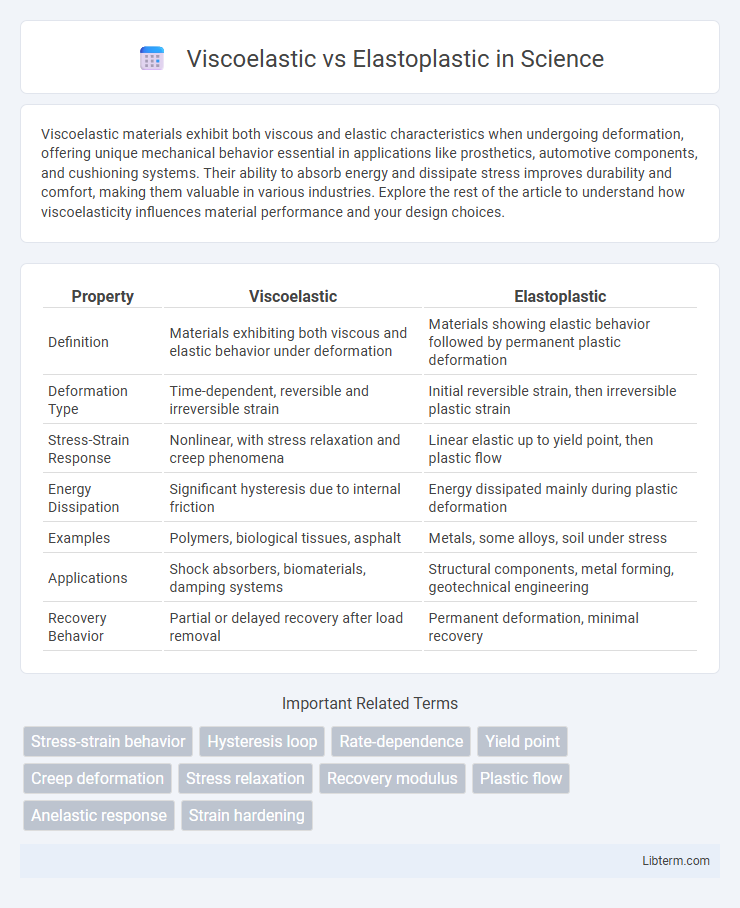

| Property | Viscoelastic | Elastoplastic |

|---|---|---|

| Definition | Materials exhibiting both viscous and elastic behavior under deformation | Materials showing elastic behavior followed by permanent plastic deformation |

| Deformation Type | Time-dependent, reversible and irreversible strain | Initial reversible strain, then irreversible plastic strain |

| Stress-Strain Response | Nonlinear, with stress relaxation and creep phenomena | Linear elastic up to yield point, then plastic flow |

| Energy Dissipation | Significant hysteresis due to internal friction | Energy dissipated mainly during plastic deformation |

| Examples | Polymers, biological tissues, asphalt | Metals, some alloys, soil under stress |

| Applications | Shock absorbers, biomaterials, damping systems | Structural components, metal forming, geotechnical engineering |

| Recovery Behavior | Partial or delayed recovery after load removal | Permanent deformation, minimal recovery |

Introduction to Material Behavior

Viscoelastic materials exhibit time-dependent strain under stress, combining both viscous and elastic characteristics that allow gradual deformation and energy dissipation. Elastoplastic materials display elastic behavior up to a yield point, followed by irreversible plastic deformation, crucial in metal forming and structural analysis. Understanding these behaviors enables accurate prediction of material response under load, essential for design and failure prevention in engineering applications.

Defining Viscoelastic Materials

Viscoelastic materials exhibit both viscous and elastic characteristics when deformed, meaning they can dissipate energy through internal friction while also recovering their original shape after stress removal. Unlike elastoplastic materials, which undergo permanent deformation once their yield point is surpassed, viscoelastic materials display time-dependent strain that gradually recovers. Key examples include polymers like polyurethane and biological tissues, where stress relaxation and creep behavior are critical to performance in applications such as medical devices and damping systems.

Understanding Elastoplastic Materials

Elastoplastic materials exhibit a combination of elastic behavior, where they recover their shape after stress removal, and plastic behavior, characterized by permanent deformation beyond the yield point. Understanding elastoplasticity involves analyzing stress-strain relationships, yield criteria, and hardening mechanisms that govern irreversible changes in material structure. This knowledge is crucial for predicting the performance and failure of metals, polymers, and composites under cyclic or incremental loading conditions.

Key Differences Between Viscoelastic and Elastoplastic

Viscoelastic materials exhibit time-dependent strain under stress, combining both viscous and elastic behavior, whereas elastoplastic materials display permanent deformation after yielding without time dependence. Viscoelasticity involves energy dissipation through internal friction and reversible elastic recovery, while elastoplastic behavior involves irreversible plastic deformation once the yield point is exceeded. Mechanical models representing viscoelasticity include the Maxwell and Kelvin-Voigt models, contrasting with elastoplastic models like the Prandtl-Reuss model emphasizing yield criteria and plastic flow.

Stress-Strain Responses Explained

Viscoelastic materials exhibit time-dependent stress-strain responses where stress relaxes under constant strain due to their combined viscous and elastic behavior, showing hysteresis and gradual recovery. Elastoplastic materials, in contrast, demonstrate a yield point separating elastic deformation from permanent plastic deformation, with stress-strain curves featuring a linear elastic region followed by a plastic plateau or hardening phase. Stress relaxation and creep characterize viscoelasticity, while irreversible strain and distinct yield stress define elastoplastic responses.

Applications of Viscoelastic Materials

Viscoelastic materials, characterized by time-dependent strain and stress relaxation, are widely used in applications such as vibration damping, shock absorption, and flexible electronics. These properties make them ideal for products like automotive bushings, medical implants, and cushioning foams, where energy dissipation and durability are critical. Compared to elastoplastic materials, which exhibit permanent deformation after yielding, viscoelastic materials provide reversible deformation and improved fatigue resistance in cyclic loading environments.

Applications of Elastoplastic Materials

Elastoplastic materials are widely utilized in structural engineering and manufacturing due to their ability to undergo permanent deformation while maintaining strength and stability, making them ideal for metal forming processes such as stamping and forging. These materials are critical in automotive and aerospace industries where components must absorb energy during impact without fracturing, enhancing safety and durability. Their applications extend to seismic-resistant building designs, where the controlled plastic deformation helps dissipate energy and prevent catastrophic failure during earthquakes.

Material Selection Criteria

Viscoelastic materials exhibit time-dependent strain and recover slowly after deformation, making them suitable for applications requiring energy dissipation and vibration damping, while elastoplastic materials permanently deform beyond their yield strength, ideal for structural components needing permanent shape change without fracture. Material selection criteria prioritize viscoelastic polymers like polyurethane or silicone for flexible seals and dampers, whereas elastoplastic metals such as steel and aluminum alloys are chosen for load-bearing frames and forming processes. Understanding stress-strain behavior, recovery rate, temperature sensitivity, and durability guides engineers in choosing between viscoelastic and elastoplastic materials for specific mechanical performance and lifecycle requirements.

Experimental Methods for Characterization

Experimental methods for characterizing viscoelastic materials often involve dynamic mechanical analysis (DMA), where oscillatory stress or strain tests reveal storage and loss moduli across frequencies and temperatures. Elastoplastic behavior is typically assessed through stress-strain testing under controlled loading-unloading cycles, highlighting yield points, permanent deformation, and strain hardening using tensile or compression tests. Advanced techniques like nanoindentation and digital image correlation (DIC) provide localized mechanical property measurement and deformation tracking for both viscoelastic and elastoplastic materials.

Future Trends in Material Science

Future trends in material science emphasize the development of hybrid materials that combine viscoelastic damping properties with elastoplastic strength for enhanced performance in aerospace and biomedical applications. Advances in nanotechnology and molecular engineering enable precise control over viscoelastic relaxation times and elastoplastic yield points, optimizing fatigue resistance and energy dissipation. Emerging smart materials with adaptive viscoelastic-elastoplastic behavior provide real-time response to environmental stimuli, driving innovation in wearable devices and soft robotics.

Viscoelastic Infographic

libterm.com

libterm.com