The Z-type printer offers high-speed, precise printing ideal for industrial and commercial applications where efficiency and quality are crucial. Its advanced technology ensures minimal maintenance and consistent output, saving your business time and resources. Discover how a Z-type printer can transform your printing needs by reading the rest of this article.

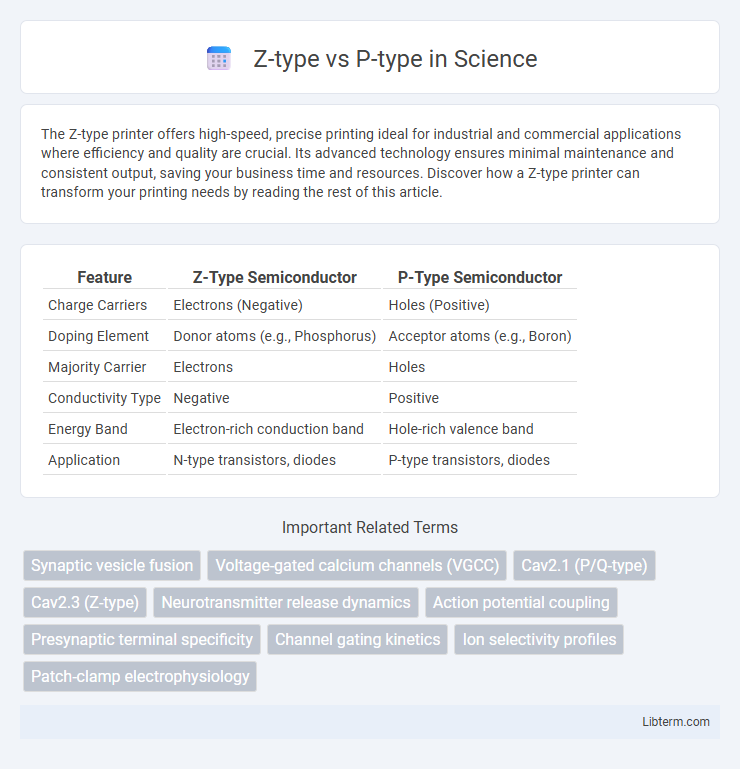

Table of Comparison

| Feature | Z-Type Semiconductor | P-Type Semiconductor |

|---|---|---|

| Charge Carriers | Electrons (Negative) | Holes (Positive) |

| Doping Element | Donor atoms (e.g., Phosphorus) | Acceptor atoms (e.g., Boron) |

| Majority Carrier | Electrons | Holes |

| Conductivity Type | Negative | Positive |

| Energy Band | Electron-rich conduction band | Hole-rich valence band |

| Application | N-type transistors, diodes | P-type transistors, diodes |

Introduction to Z-type and P-type

Z-type and P-type refer to classifications of semiconductor materials based on their charge carrier types. Z-type semiconductors, also known as n-type, have an abundance of electrons as majority charge carriers, created by doping with elements that provide extra electrons. P-type semiconductors contain holes as majority carriers, formed by introducing acceptor impurities that create electron deficiencies in the material's crystal lattice.

Key Differences Between Z-type and P-type

Z-type and P-type refer to semiconductor materials doped to have different charge carrier types; Z-type is typically associated with n-type semiconductors containing excess electrons, while P-type semiconductors have an abundance of holes due to acceptor impurities. The key difference lies in the majority charge carriers: Z-type has electrons as the primary carriers, enhancing electrical conductivity through negative charge, whereas P-type relies on holes, which act as positive charge carriers. This distinction affects their use in electronic devices, influencing current flow, junction behavior, and the formation of p-n junctions essential for diodes, transistors, and solar cells.

Structural Characteristics of Z-type

Z-type thermoelectric materials exhibit a unique crystalline structure characterized by their zigzag atomic chains, which enhance phonon scattering and reduce thermal conductivity. Their lattice framework often consists of layered compounds with anisotropic bonding, contributing to superior electrical conductivity along specific crystallographic directions. These structural characteristics boost the Seebeck coefficient and improve overall thermoelectric efficiency compared to conventional P-type materials.

Structural Characteristics of P-type

P-type semiconductors are characterized by the presence of holes as the majority charge carriers, created through the introduction of trivalent impurities such as boron or gallium into the intrinsic semiconductor lattice. The defect in the crystal structure occurs because these trivalent dopants have one fewer valence electron than the tetravalent host atoms, resulting in an electron deficiency that facilitates hole conduction. This structural characteristic leads to increased positive charge mobility and distinct electrical properties compared to n-type or intrinsic materials.

Applications of Z-type Materials

Z-type materials are primarily used in spintronic devices due to their unique magnetic properties that enable efficient spin current generation and manipulation. These materials find applications in magnetic sensors, non-volatile memory cells, and microwave devices, where their strong spin Hall effect enhances device performance. Their ability to convert charge currents into spin currents is crucial for developing advanced spin-orbit torque technologies in next-generation electronics.

Applications of P-type Materials

P-type materials, characterized by their positive charge carriers (holes), are extensively used in semiconductor applications such as photovoltaic cells, where they form the anode layer in solar panels to facilitate current flow. In thermoelectric devices, P-type materials complement N-type counterparts to create temperature gradients for electricity generation. Their role in diode and transistor fabrication is crucial for controlling electrical conductivity and enabling efficient electronic switching and amplification.

Classification Criteria: Z-type vs P-type

Z-type and P-type classification criteria in materials science primarily differentiate based on their electronic behavior and charge carrier type. Z-type materials are typically characterized by the presence of both electrons and holes as charge carriers, exhibiting ambipolar conduction, whereas P-type materials predominantly have holes as the primary charge carriers, resulting from acceptor doping. The distinction is essential for tailoring semiconductor properties in applications such as thermoelectrics and optoelectronics.

Advantages and Disadvantages of Z-type

Z-type thermoelectric modules offer higher efficiency in power generation due to their ability to handle greater temperature gradients compared to P-type modules. They provide better mechanical stability and durability, which enhances long-term performance in harsh environments. However, Z-type modules are generally more expensive and complex to manufacture, leading to higher initial costs and potential integration challenges.

Advantages and Disadvantages of P-type

P-type semiconductors, created by doping with elements like boron, offer advantages such as higher hole mobility, which enhances conductivity in certain electronic applications. However, they typically exhibit lower electron mobility compared to N-type semiconductors, leading to slower device performance in some circuits. The balance between hole concentration and mobility impacts the choice of P-type materials in designing efficient transistors and solar cells.

How to Choose Between Z-type and P-type

Choosing between Z-type and P-type semiconductors depends on the desired charge carrier: electrons for Z-type (n-type) and holes for P-type. Z-type materials are preferred for applications requiring high electron mobility and negative charge conduction, while P-type semiconductors suit devices leveraging positive charge flow and hole conduction. Device architecture, conductivity, and intended electrical behavior are critical factors influencing the decision in semiconductor design.

Z-type Infographic

libterm.com

libterm.com