Mechanical systems play a crucial role in various industries by converting energy into motion and performing essential tasks efficiently. Understanding the principles behind mechanical components such as gears, levers, and pulleys can enhance your ability to troubleshoot and optimize machinery. Explore the full article to discover detailed insights into mechanical applications and maintenance tips.

Table of Comparison

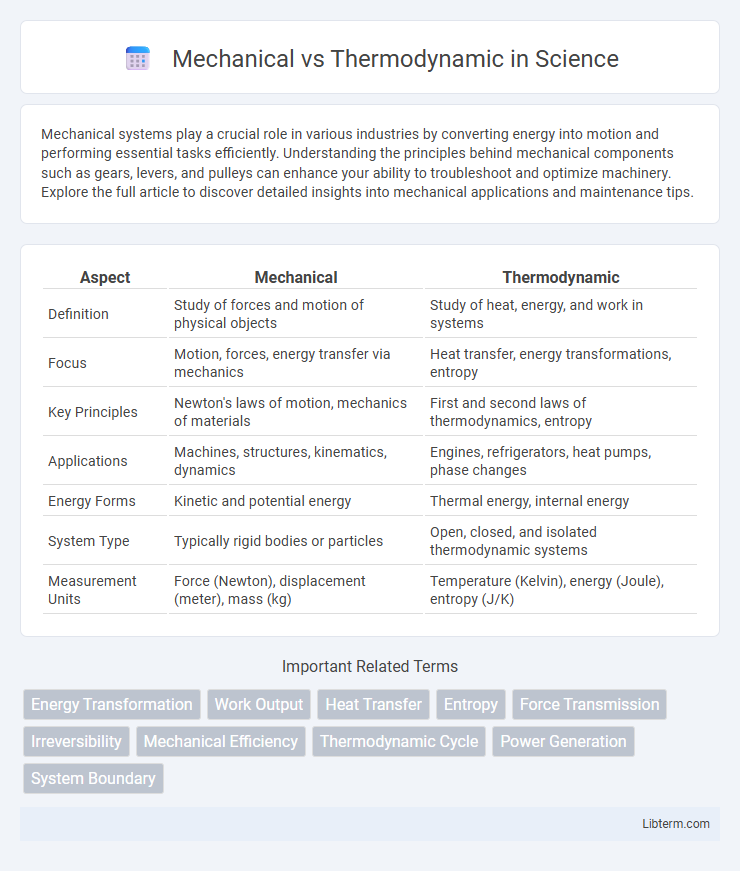

| Aspect | Mechanical | Thermodynamic |

|---|---|---|

| Definition | Study of forces and motion of physical objects | Study of heat, energy, and work in systems |

| Focus | Motion, forces, energy transfer via mechanics | Heat transfer, energy transformations, entropy |

| Key Principles | Newton's laws of motion, mechanics of materials | First and second laws of thermodynamics, entropy |

| Applications | Machines, structures, kinematics, dynamics | Engines, refrigerators, heat pumps, phase changes |

| Energy Forms | Kinetic and potential energy | Thermal energy, internal energy |

| System Type | Typically rigid bodies or particles | Open, closed, and isolated thermodynamic systems |

| Measurement Units | Force (Newton), displacement (meter), mass (kg) | Temperature (Kelvin), energy (Joule), entropy (J/K) |

Understanding Mechanical Systems

Mechanical systems involve the study of forces, motion, and energy transfer within physical structures and machinery, focusing on components like gears, levers, and engines to perform specific tasks. Understanding mechanical systems requires analyzing kinematics, dynamics, and material properties to predict behavior under various operational conditions. Thermodynamics complements this by examining energy conversion, heat transfer, and the principles of work, which are critical for optimizing mechanical system efficiency and performance.

Fundamentals of Thermodynamics

Thermodynamics studies energy transformations and the principles governing heat, work, and entropy in macroscopic systems, emphasizing the laws of thermodynamics and state functions such as enthalpy and internal energy. Mechanical principles address forces, motion, and energy transfer in physical systems, focusing on Newtonian mechanics, kinematics, and dynamics. Understanding thermodynamics fundamentals enables analysis of energy efficiency, engine performance, and phase changes beyond purely mechanical motion.

Key Differences Between Mechanical and Thermodynamic Processes

Mechanical processes involve the study of forces, motion, and energy transfer in physical systems, focusing on work done by or on an object without altering its internal energy. Thermodynamic processes analyze heat, work, and energy transformations within systems, emphasizing changes in state variables like temperature, pressure, and entropy. Key differences lie in mechanical processes typically dealing with macroscopic motion and forces, while thermodynamic processes concentrate on microscopic energy interactions and equilibrium states.

Core Principles Governing Mechanical Operations

Mechanical operations rely on the principles of force, motion, and energy transfer through physical components like gears, levers, and pulleys. Core principles include Newton's laws of motion, the conservation of mechanical energy, and the principles of work and power applied in systems to achieve desired mechanical output. These laws govern how mechanical devices convert input force into controlled motion and energy efficiency without directly involving heat or thermal effects.

Major Laws of Thermodynamics

The major laws of thermodynamics include the Zeroth Law, which establishes thermal equilibrium; the First Law, stating energy conservation and the equivalence of work and heat; the Second Law, introducing entropy and the direction of spontaneous processes; and the Third Law, defining absolute zero temperature and the behavior of entropy at that limit. Mechanical systems often apply these laws to analyze energy transformations and work, while thermodynamic principles govern heat interactions and efficiency. Understanding these laws is essential for optimizing engines, refrigerators, and energy conversion systems.

Applications of Mechanical Systems in Industry

Mechanical systems in industry are essential for manufacturing, material handling, and automation processes, providing efficient motion control and power transmission. These systems enable precision machining, conveyor operations, and robotic assembly lines, enhancing productivity and reliability. Their applications span automotive production, aerospace component fabrication, and heavy machinery operation, driving industrial innovation and cost-effectiveness.

Thermodynamic Processes in Energy Conversion

Thermodynamic processes play a critical role in energy conversion by transforming heat into useful work through cycles such as the Carnot, Rankine, and Otto cycles. These processes rely on principles like entropy, enthalpy, and internal energy to optimize efficiency in engines, turbines, and refrigerators. Understanding the thermodynamic behavior of working fluids under different conditions enables the design of systems that maximize energy output while minimizing losses.

Efficiency Comparison: Mechanical vs Thermodynamic

Mechanical efficiency typically measures the ratio of useful work output to input energy, often exceeding 90% in well-maintained engines, while thermodynamic efficiency is governed by the Carnot limit and real-world factors like entropy and heat loss, generally resulting in lower maximum efficiency percentages. Internal combustion engines, as mechanical systems, achieve practical efficiencies around 25-30%, whereas thermodynamic cycles such as the Rankine or Brayton cycle can reach 40-60% efficiency in optimized power plants due to better heat recovery and cycle design. The comparison highlights that mechanical efficiency focuses on minimizing friction and mechanical losses, whereas thermodynamic efficiency depends on the fundamental limits of energy conversion and heat transfer.

Real-World Examples and Case Studies

Mechanical systems, such as engines and elevators, demonstrate energy conversion and force transmission based on physical laws, while thermodynamic processes govern heat transfer and energy efficiency in power plants and refrigeration units. Real-world case studies highlight how mechanical engineering optimizes structural integrity and motion mechanics, whereas thermodynamics focuses on maximizing thermal efficiency and minimizing entropy in systems like gas turbines and heat exchangers. The integration of both fields is critical in automotive design, where internal combustion engines rely on mechanical components and thermodynamic cycles to improve fuel efficiency and reduce emissions.

Choosing the Right Approach: Mechanical or Thermodynamic

Choosing between mechanical and thermodynamic approaches depends on the specific problem's nature: mechanical methods are ideal for analyzing forces, motion, and deformation in solid objects, while thermodynamic approaches excel at studying energy transformations, heat transfer, and system efficiency. Mechanical analysis often involves Newtonian mechanics and material properties, whereas thermodynamics relies on principles like entropy, enthalpy, and state functions to describe system behavior. Understanding the problem context and desired outcomes ensures selecting the approach that provides accurate, efficient, and relevant results for engineering or physical analysis.

Mechanical Infographic

libterm.com

libterm.com