Mechanical systems play a crucial role in various industries by converting energy into motion and performing essential tasks with precision and reliability. Understanding the fundamentals of mechanical engineering can enhance your ability to troubleshoot and optimize machinery for better performance and efficiency. Explore the rest of the article to discover key insights and practical tips that will improve your mechanical knowledge.

Table of Comparison

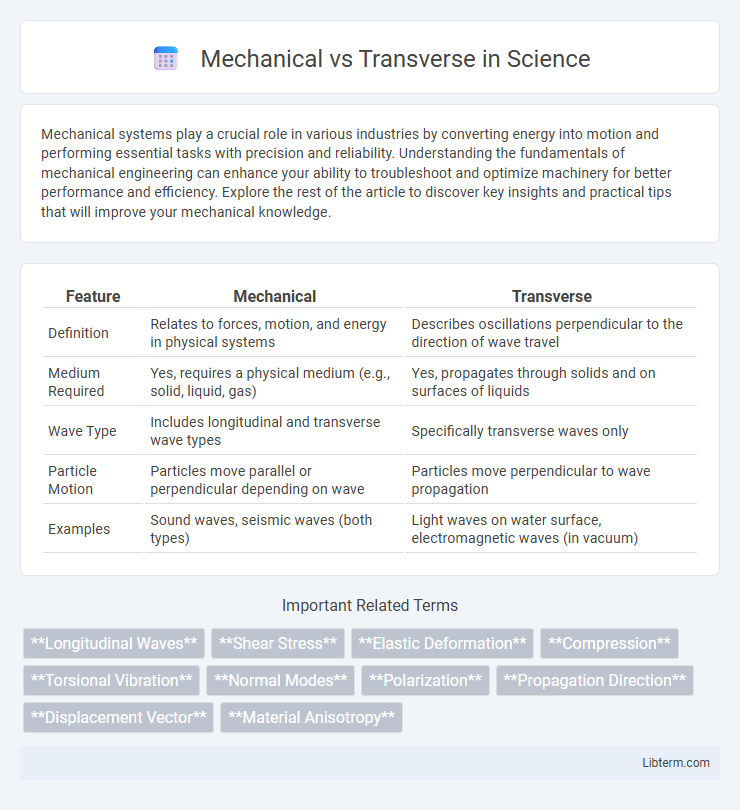

| Feature | Mechanical | Transverse |

|---|---|---|

| Definition | Relates to forces, motion, and energy in physical systems | Describes oscillations perpendicular to the direction of wave travel |

| Medium Required | Yes, requires a physical medium (e.g., solid, liquid, gas) | Yes, propagates through solids and on surfaces of liquids |

| Wave Type | Includes longitudinal and transverse wave types | Specifically transverse waves only |

| Particle Motion | Particles move parallel or perpendicular depending on wave | Particles move perpendicular to wave propagation |

| Examples | Sound waves, seismic waves (both types) | Light waves on water surface, electromagnetic waves (in vacuum) |

Introduction to Mechanical vs Transverse

Mechanical and transverse waves differ fundamentally in particle motion relative to wave propagation; mechanical waves require a medium to travel through solids, liquids, or gases, while transverse waves involve particles oscillating perpendicular to the wave's direction. Mechanical waves encompass both transverse and longitudinal types, with examples including sound waves (longitudinal) and water waves (transverse). Understanding these distinctions is essential in fields such as physics and engineering, influencing wave behavior analysis and practical applications.

Defining Mechanical and Transverse Concepts

Mechanical systems involve forces and motions related to physical components such as gears, levers, and engines, emphasizing the transmission of power and movement through solid materials. Transverse concepts refer to phenomena or waves that propagate perpendicular to the direction of an initial disturbance, commonly observed in mechanical waves like vibrations on a string or seismic S-waves. Understanding mechanical and transverse principles is crucial for engineering applications involving structural dynamics and wave mechanics.

Key Differences Between Mechanical and Transverse

Mechanical keyboards feature individual mechanical switches beneath each key, offering tactile feedback, durability, and precise actuation, whereas transverse keyboards utilize a membrane or rubber dome layer for key presses, resulting in quieter but less responsive input. Mechanical switches are preferred for gaming and typing due to their responsiveness and long lifespan, typically rated for 50 million keystrokes, while transverse designs are often found in budget-friendly or portable devices with a lifespan closer to 5 million keystrokes. The key travel distance and actuation force also differ, with mechanical keyboards providing customizable options for user preference, unlike the fixed settings in transverse membrane keyboards.

Applications of Mechanical and Transverse Approaches

Mechanical approaches are widely used in automotive engineering for suspension systems, where precise control of wheel movement enhances vehicle stability and comfort. Transverse methods are prevalent in structural engineering, particularly in bridge construction, to effectively distribute loads and resist lateral forces. Both approaches find crucial applications in aerospace design, optimizing aircraft wing structures and fuselage integrity for improved aerodynamics and strength.

Advantages of Mechanical Methods

Mechanical methods offer precise control over cutting and shaping materials, leading to higher accuracy and consistent results in manufacturing processes. These techniques provide superior durability and strength of components due to enhanced material properties achieved through methods such as milling or turning. Mechanical methods also improve efficiency by enabling faster production cycles and minimizing material waste compared to transverse techniques.

Benefits of Transverse Techniques

Transverse techniques offer enhanced energy efficiency and reduced noise levels compared to traditional mechanical systems, making them ideal for sustainable building design. Their design enables improved airflow distribution, which enhances indoor air quality and occupant comfort. These benefits contribute to lower maintenance costs and longer system lifespan in HVAC and industrial applications.

Mechanical vs Transverse: Performance Comparison

Mechanical keyboards offer superior tactile feedback and faster response times compared to transverse membrane keyboards, making them ideal for high-performance gaming and typing accuracy. Transverse membrane keyboards, while quieter and more affordable, often lack the durability and precision of mechanical switches, resulting in slower actuation and less consistent performance. Mechanical switches provide individualized key actuation, enhancing overall reliability and user experience under intense usage conditions.

Industry Examples: Mechanical vs Transverse

Mechanical and transverse processes are critical in manufacturing industries, with mechanical methods often applied in automotive assembly for precise machining and cutting operations. Transverse techniques dominate textile production, where fibers are aligned perpendicularly to the production flow to enhance fabric strength and elasticity. In aerospace manufacturing, mechanical processes shape structural components, while transverse lamination improves composite material performance under stress.

Factors to Consider When Choosing Mechanical or Transverse

When choosing between mechanical and transverse engine layouts, consider factors such as vehicle size, weight distribution, and intended performance. Mechanical layouts often offer greater durability and easier maintenance, while transverse engines provide improved space efficiency and better fuel economy, making them suitable for compact cars. Evaluating drivetrain complexity, repair costs, and vehicle handling characteristics is essential to selecting the optimal configuration.

Conclusion: Mechanical vs Transverse—Which Is Better?

Mechanical transmission systems offer superior durability and efficiency in heavy-duty applications, while transverse transmissions excel in compact design and fuel economy for front-wheel-drive vehicles. The choice depends heavily on the vehicle's purpose, with mechanical setups favored in performance and load-bearing scenarios, and transverse layouts preferred for urban and light-duty use. Evaluating the specific driving conditions and maintenance requirements is essential to determine the optimal transmission type.

Mechanical Infographic

libterm.com

libterm.com