Ductile materials can undergo significant deformation without breaking, making them essential in construction and manufacturing for their ability to absorb energy and withstand stress. Their flexibility allows for shaping and bending while maintaining strength, which is crucial in applications ranging from metalwork to electronics. Explore the rest of the article to understand how ductility impacts the performance and durability of various materials in your projects.

Table of Comparison

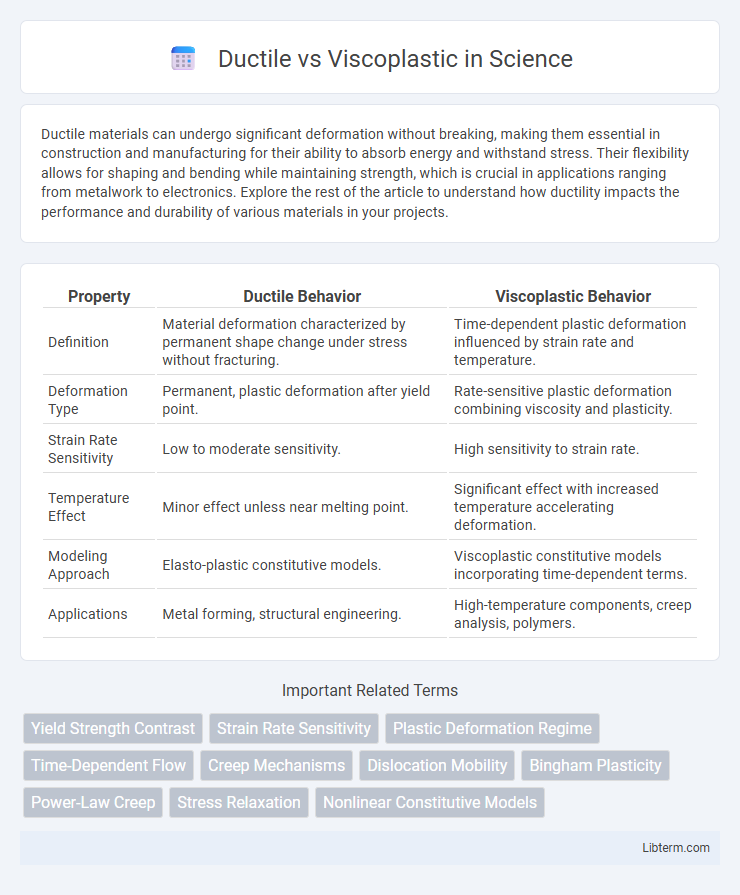

| Property | Ductile Behavior | Viscoplastic Behavior |

|---|---|---|

| Definition | Material deformation characterized by permanent shape change under stress without fracturing. | Time-dependent plastic deformation influenced by strain rate and temperature. |

| Deformation Type | Permanent, plastic deformation after yield point. | Rate-sensitive plastic deformation combining viscosity and plasticity. |

| Strain Rate Sensitivity | Low to moderate sensitivity. | High sensitivity to strain rate. |

| Temperature Effect | Minor effect unless near melting point. | Significant effect with increased temperature accelerating deformation. |

| Modeling Approach | Elasto-plastic constitutive models. | Viscoplastic constitutive models incorporating time-dependent terms. |

| Applications | Metal forming, structural engineering. | High-temperature components, creep analysis, polymers. |

Introduction to Ductile and Viscoplastic Materials

Ductile materials exhibit significant plastic deformation before fracture, characterized by their ability to stretch or bend without breaking, commonly seen in metals like steel and copper. Viscoplastic materials combine viscosity and plasticity, allowing them to undergo time-dependent irreversible deformation under sustained stress, often relevant in polymers and geological materials. Understanding the distinct mechanical behaviors of ductile and viscoplastic materials is crucial for applications involving structural integrity and long-term load-bearing performance.

Defining Ductility: Key Characteristics

Ductility refers to a material's ability to undergo significant plastic deformation before fracture, characterized by its capacity to stretch or elongate under tensile stress without cracking. Key characteristics include high strain-to-failure, substantial energy absorption, and notable malleability, allowing metals like copper and aluminum to be drawn into wires. In contrast to viscoplastic behavior, which incorporates time-dependent deformation and rate sensitivity, ductility primarily emphasizes irreversible shape change under static or quasi-static loading conditions.

Understanding Viscoplasticity: Main Features

Viscoplasticity describes materials that exhibit time-dependent irreversible deformation under stress, combining both viscous and plastic behavior. Unlike purely ductile materials, which deform plastically without significant time dependence, viscoplastic materials show strain rate sensitivity and stress relaxation over time. Key features include a yield stress threshold, after which flow occurs gradually, and a dependence on temperature and strain rate, critical for modeling metals, polymers, and high-temperature components.

Stress-Strain Behavior: Ductile vs Viscoplastic

Ductile materials exhibit a clear yield point followed by uniform plastic deformation characterized by a linear elastic region transitioning into plastic flow, showing permanent strain after unloading. Viscoplastic behavior combines both viscous and plastic characteristics, displaying time-dependent strain where stress-strain curves show gradual deformation under constant stress, influenced by strain rate and temperature. The key distinction lies in ductile materials exhibiting instantaneous plastic deformation beyond yield, while viscoplastic materials demonstrate rate-dependent deformation with delayed strain accumulation.

Microstructural Differences

Ductile materials exhibit microstructures characterized by the presence of dislocation slip systems and grain boundary sliding, enabling significant plastic deformation before failure. Viscoplastic behavior arises from time-dependent microstructural mechanisms such as creep deformation, grain boundary diffusion, and dislocation climb under sustained stress and elevated temperature. The key microstructural difference lies in the rate-dependent atomic diffusion processes dominating viscoplasticity, contrasting with the instantaneous dislocation movements governing ductility.

Temperature and Strain Rate Effects

Ductile materials exhibit significant plastic deformation before failure, with temperature increases generally enhancing ductility by enabling atomic mobility and dislocation motion. Viscoplastic behavior combines viscous and plastic deformation mechanisms, showing strong sensitivity to both temperature and strain rate, where higher temperatures typically reduce flow stress and lower strain rates facilitate time-dependent deformation. Strain rate effects in viscoplastic materials result in strain rate hardening, while ductile materials primarily demonstrate rate-independent plasticity except at extreme rates or temperatures.

Applications in Engineering and Industry

Ductile materials, known for their ability to undergo significant plastic deformation before rupture, are widely used in structural engineering applications such as bridge construction, automotive components, and metal forming processes due to their toughness and energy absorption capabilities. Viscoplastic materials, characterized by time-dependent strain under stress, find critical applications in high-temperature environments like turbine blades, creep-resistant alloys, and polymer processing where deformation behavior over time impacts performance and longevity. Understanding the distinction between ductile and viscoplastic responses is essential for material selection in industries requiring specific mechanical properties under varying operational conditions.

Testing Methods and Standards

Ductile materials are typically evaluated through tensile testing following ASTM E8/E8M standards to assess yield strength, elongation, and fracture behavior under plastic deformation. Viscoplastic materials require specialized rheological or creep testing methods, such as ASTM D2990 for creep behavior or strain rate jump tests, to capture time-dependent deformation characteristics. Both testing approaches emphasize precise strain measurement techniques like extensometry or digital image correlation to ensure accurate characterization of mechanical responses under controlled loading conditions.

Advantages and Limitations

Ductile materials exhibit significant plastic deformation before failure, allowing for energy absorption and improved toughness, making them ideal for applications requiring high impact resistance. Viscoplastic materials combine viscosity and plasticity, enabling time-dependent deformation under stress, which is advantageous for modeling creep and relaxation in metals at elevated temperatures. Limitations include ductile materials' susceptibility to necking and limited applicability under high-temperature conditions, while viscoplastic models can be computationally intensive and less accurate for rapid loading scenarios.

Summary and Future Perspectives

Ductile behavior describes materials that undergo significant plastic deformation before fracture, characterized by stress-strain curves with a well-defined yield point, whereas viscoplasticity incorporates time-dependent strain rates and temperature effects impacting material flow. Future research is advancing multiscale modeling techniques to capture viscoplastic phenomena more accurately, integrating molecular dynamics with continuum mechanics to predict lifespan under cyclic loading and extreme conditions. The development of adaptive materials that combine ductile robustness with viscoplastic damping properties is a key area for enhancing structural resilience and longevity in aerospace and automotive industries.

Ductile Infographic

libterm.com

libterm.com