Elastic materials return to their original shape after being stretched or compressed, making them essential in various applications such as clothing, industrial components, and medical devices. Understanding the behavior of elasticity can improve product design and enhance functionality in everyday items you use. Explore the article to learn more about the science of elasticity and its practical uses.

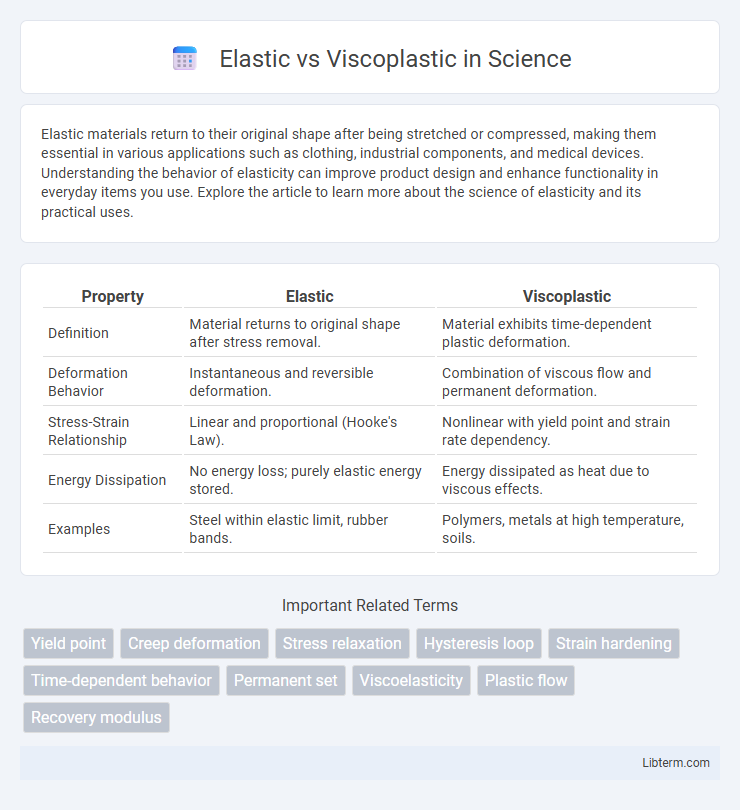

Table of Comparison

| Property | Elastic | Viscoplastic |

|---|---|---|

| Definition | Material returns to original shape after stress removal. | Material exhibits time-dependent plastic deformation. |

| Deformation Behavior | Instantaneous and reversible deformation. | Combination of viscous flow and permanent deformation. |

| Stress-Strain Relationship | Linear and proportional (Hooke's Law). | Nonlinear with yield point and strain rate dependency. |

| Energy Dissipation | No energy loss; purely elastic energy stored. | Energy dissipated as heat due to viscous effects. |

| Examples | Steel within elastic limit, rubber bands. | Polymers, metals at high temperature, soils. |

Introduction to Elastic and Viscoplastic Behavior

Elastic behavior describes materials that deform under stress and return to their original shape upon stress removal, characterized by a linear stress-strain relationship as defined by Hooke's Law. Viscoplastic behavior involves time-dependent, irreversible deformation where materials exhibit both viscous flow and plasticity, leading to permanent shape changes under sustained stress. Understanding these behaviors is critical in material science for predicting performance in applications subject to mechanical loading.

Fundamental Definitions: Elasticity vs. Viscoplasticity

Elasticity refers to a material's ability to return to its original shape after the removal of an applied stress, characterized by reversible deformation and described by Hooke's Law. Viscoplasticity combines viscous and plastic behaviors, where a material undergoes irreversible deformation over time under stress, exhibiting both time-dependent flow and permanent shape change. Fundamental differences include elastic materials storing energy elastically without permanent strain, whereas viscoplastic materials display strain accumulation that depends on stress magnitude and duration.

Key Differences in Material Response

Elastic materials deform reversibly when subjected to stress, returning to their original shape once the load is removed, with strain proportional to applied stress following Hooke's law. Viscoplastic materials exhibit a combination of viscous and plastic behavior, showing time-dependent deformation and permanent strain after stress exceeds the yield point. Key differences include elastic materials' instantaneous recovery and linear stress-strain relationship versus viscoplastic materials' irrecoverable deformation and rate-dependent flow behavior.

Stress-Strain Relationships Explained

Elastic materials exhibit a linear stress-strain relationship where deformation is fully recoverable upon load removal, characterized by Hooke's Law with stress proportional to strain. Viscoplastic behavior combines viscosity and plasticity, showing non-linear, time-dependent deformation with permanent strain after yield stress is surpassed. Understanding these distinctions is crucial for modeling materials under varying load conditions, ensuring accurate predictions of deformation and failure.

Applications in Engineering and Industry

Elastic materials are widely used in mechanical springs, vibration isolators, and load-bearing structures due to their ability to return to original shape after deformation, optimizing energy storage and release. Viscoplastic materials find critical applications in metal forming, welding, and structural damping where permanent deformation under stress is advantageous for shaping metals and absorbing energy. Engineering disciplines leverage elasticity for resilience and viscoplasticity for controlled deformation and dissipation in systems like automotive crash components and seismic dampers.

Advantages and Limitations of Elastic Materials

Elastic materials exhibit the advantage of returning to their original shape after deformation, providing predictable and reversible mechanical behavior essential for applications like springs and shock absorbers. Their limitation lies in their inability to permanently deform, which restricts energy dissipation and adaptability under prolonged or excessive stress, often leading to failure in applications requiring plastic deformation. Elasticity ensures durability and consistent performance but can be insufficient for structures needing to absorb high impact or undergo permanent shape changes.

Advantages and Limitations of Viscoplastic Materials

Viscoplastic materials exhibit high resistance to permanent deformation under long-term loads, providing superior energy dissipation and damping capabilities compared to purely elastic materials. Their ability to undergo irreversible strain without fracturing makes them ideal for applications involving sustained stress and cyclic loading, such as automotive and structural components. However, viscoplasticity introduces complexity in modeling and predicting material behavior due to time-dependent strain, and these materials may suffer from reduced stiffness and eventual creep failure under prolonged high stress conditions.

Real-World Examples and Case Studies

Elastic materials such as steel beams in construction demonstrate reversible deformation under load, maintaining structural integrity after stress removal. Viscoplastic materials like asphalt pavements exhibit time-dependent permanent deformation under traffic loads, requiring careful modeling in civil engineering to predict long-term performance. Case studies in automotive crash safety utilize elastic modeling for metal frame behavior and viscoplastic analysis for energy-absorbing components to optimize impact resistance.

Selection Criteria: When to Choose Elastic or Viscoplastic

Selection criteria between elastic and viscoplastic materials depend on the application's deformation and time-dependent behavior requirements. Choose elastic materials for applications needing immediate, reversible deformation under stress without permanent shape change, such as springs or structural components. Viscoplastic materials are ideal when modeling time-dependent, irreversible deformation under load, common in creep analysis or metal forming processes.

Future Trends in Material Science: Elastic and Viscoplastic Perspectives

Future trends in material science emphasize developing smart materials that combine elastic and viscoplastic properties for enhanced durability and adaptability in aerospace and biomedical applications. Advanced computational modeling and machine learning enable precise prediction and optimization of material behavior under complex loading conditions, accelerating innovation in energy absorption systems and flexible electronics. Research on metal-organic frameworks and polymer composites with tunable viscoplasticity is driving breakthroughs in sustainable, high-performance materials for next-generation infrastructure and wearable technology.

Elastic Infographic

libterm.com

libterm.com