Cold patch asphalt provides a quick and easy solution for repairing potholes and cracks in roads without the need for heating. It is designed for immediate use, offering durability and weather resistance to extend the lifespan of your pavement. Discover how cold patch products can save you time and money by reading the rest of the article.

Table of Comparison

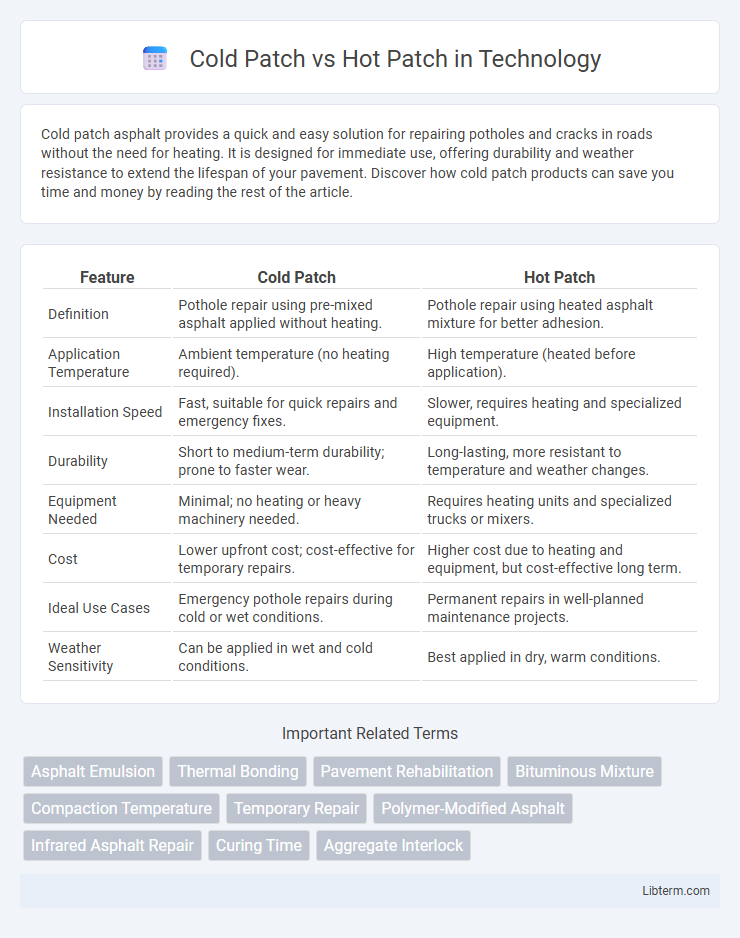

| Feature | Cold Patch | Hot Patch |

|---|---|---|

| Definition | Pothole repair using pre-mixed asphalt applied without heating. | Pothole repair using heated asphalt mixture for better adhesion. |

| Application Temperature | Ambient temperature (no heating required). | High temperature (heated before application). |

| Installation Speed | Fast, suitable for quick repairs and emergency fixes. | Slower, requires heating and specialized equipment. |

| Durability | Short to medium-term durability; prone to faster wear. | Long-lasting, more resistant to temperature and weather changes. |

| Equipment Needed | Minimal; no heating or heavy machinery needed. | Requires heating units and specialized trucks or mixers. |

| Cost | Lower upfront cost; cost-effective for temporary repairs. | Higher cost due to heating and equipment, but cost-effective long term. |

| Ideal Use Cases | Emergency pothole repairs during cold or wet conditions. | Permanent repairs in well-planned maintenance projects. |

| Weather Sensitivity | Can be applied in wet and cold conditions. | Best applied in dry, warm conditions. |

Introduction to Cold Patch and Hot Patch

Cold patch asphalt is a ready-to-use, pre-mixed material designed for quick and easy pavement repair without heating, making it ideal for emergency pothole fixes and low-traffic areas. Hot patch requires heating asphalt to high temperatures before application, providing a more durable and long-lasting repair suitable for high-traffic roadways. Understanding the key differences in application temperature, curing time, and durability helps determine the appropriate patching method for specific pavement maintenance needs.

Definition and Core Differences

Cold patch is a pre-mixed asphalt repair material used at ambient temperatures, allowing for quick and convenient pothole and crack repairs without heating. Hot patch requires heating asphalt binder and aggregate to high temperatures before application, resulting in a more durable and longer-lasting pavement repair. The core difference lies in temperature application and repair longevity, with cold patch favored for ease and speed, and hot patch chosen for enhanced performance and permanent fixes.

When to Use Cold Patch

Cold patch asphalt is ideal for temporary repairs on potholes during cold or wet weather when hot patch materials are unavailable or impractical. It requires no heating and can be applied immediately, making it a quick solution for emergency fixes or small-scale maintenance on roads and driveways. Cold patch is commonly used in areas where traffic must not be disrupted for long, providing durable results until a permanent hot patch repair can be scheduled.

When to Use Hot Patch

Hot patch asphalt is ideal for repairing potholes and cracks in cold or wet conditions, ensuring strong adhesion and faster curing compared to cold patch options. It provides a durable, long-lasting fix on active roadways where immediate traffic flow is necessary, particularly in colder seasons or areas with significant moisture. Use hot patch when permanent, high-quality repairs are required to withstand heavy traffic and variable weather.

Materials and Equipment Required

Cold patch asphalt typically requires premixed, ready-to-use materials such as polymer-modified asphalt emulsions combined with aggregate, allowing for application without heating equipment. Hot patch asphalt involves heating raw asphalt binder and aggregate to high temperatures, necessitating specialized equipment like asphalt kettles, heating tanks, and mechanical mixers to ensure proper blending and temperature management. Material choice and equipment directly impact the durability and application efficiency of road repairs, with hot patch materials generally providing stronger, longer-lasting bonds due to their thermal curing process.

Application Process: Step-by-Step Comparison

Cold patch asphalt repair involves applying a premixed, ready-to-use material directly to the damaged area without heating, requiring surface cleaning, debris removal, and compaction using a tamper or roller. Hot patch repair mandates heating the asphalt mix to temperatures between 300degF and 350degF before application, followed by thorough surface cleaning, placing the heated mix, and compacting it with heavy machinery for a durable bond. The cold patch process is quicker and more convenient for emergency fixes, while hot patching offers a longer-lasting repair due to better adhesion and curing through heat.

Durability and Longevity

Cold patch asphalt provides quick, temporary repairs but generally lacks the durability and longevity of hot patch asphalt, which undergoes higher temperature processing for better bonding and compaction. Hot patch materials create more permanent repairs by resisting cracking and deformation under heavy traffic and varying weather conditions. For long-lasting pavement maintenance, hot patch is preferred due to its superior performance and extended service life.

Cost Considerations

Cold patch asphalt is typically more cost-effective for small, emergency repairs due to its ease of application and no need for specialized equipment, making it ideal for quick fixes in budget-conscious projects. Hot patch requires higher initial expenses, including heating machinery and skilled labor, but offers superior durability and longevity, reducing long-term repair frequency and associated costs. Evaluating project scale and expected traffic volume is critical for determining the most economical choice between cold patch and hot patch asphalt repair solutions.

Environmental Impact

Cold patch asphalt requires no heating, resulting in lower energy consumption and reduced greenhouse gas emissions compared to hot patch asphalt, which demands high temperatures during application. The use of cold patch materials minimizes volatile organic compound (VOC) emissions, contributing to better air quality and less environmental pollution. Hot patch methods, while often providing longer-lasting repairs, generate more carbon emissions and consume fossil fuels, increasing their overall environmental footprint.

Choosing the Right Solution for Your Needs

Cold patch asphalt offers quick, easy application ideal for small, temporary repairs without specialized equipment, making it suitable for homeowners and minor road fixes. Hot patch asphalt provides a more durable, permanent solution requiring heated material and professional installation, best for larger projects and areas with heavy traffic. Understanding the scope and longevity requirements of the repair ensures effective selection between cold patch and hot patch materials.

Cold Patch Infographic

libterm.com

libterm.com