Screenprinting is a versatile and cost-effective printing technique used to transfer designs onto various surfaces like fabric, paper, and plastic. This method involves pushing ink through a mesh stencil to create vibrant, durable images ideal for custom apparel, promotional items, and art prints. Discover how you can leverage screenprinting for your next creative project by reading the rest of the article.

Table of Comparison

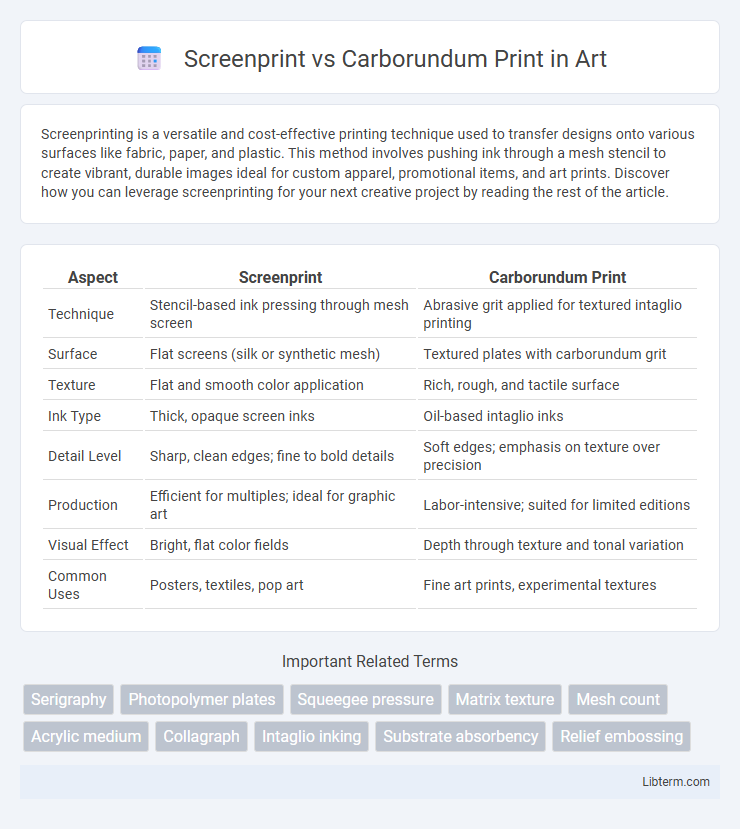

| Aspect | Screenprint | Carborundum Print |

|---|---|---|

| Technique | Stencil-based ink pressing through mesh screen | Abrasive grit applied for textured intaglio printing |

| Surface | Flat screens (silk or synthetic mesh) | Textured plates with carborundum grit |

| Texture | Flat and smooth color application | Rich, rough, and tactile surface |

| Ink Type | Thick, opaque screen inks | Oil-based intaglio inks |

| Detail Level | Sharp, clean edges; fine to bold details | Soft edges; emphasis on texture over precision |

| Production | Efficient for multiples; ideal for graphic art | Labor-intensive; suited for limited editions |

| Visual Effect | Bright, flat color fields | Depth through texture and tonal variation |

| Common Uses | Posters, textiles, pop art | Fine art prints, experimental textures |

Introduction to Printmaking Techniques

Screenprint employs a mesh stencil to transfer ink onto a substrate, allowing for bold colors and sharp lines with precise layering. Carborundum Print incorporates abrasive particles mixed with adhesive on the plate to create textured, rich tonal effects ideal for expressive prints. Both techniques offer unique methods for applying ink, providing artists with diverse options in printmaking processes.

What is Screenprinting?

Screenprinting is a versatile printmaking technique that uses a mesh stencil to transfer ink onto a substrate, allowing for rich, vibrant color application and sharp details. The process involves pushing ink through the fine mesh screen where the stencil blocks areas not meant to be printed, making it ideal for producing bold, graphic designs on various materials such as fabric, paper, and plastics. Screenprinting stands out for its durability and ability to create multiple copies efficiently without losing image quality.

What is Carborundum Printing?

Carborundum printing is a unique intaglio printmaking technique that uses powdered silicon carbide (carborundum) to create textured printing plates, allowing for rich, dense tones and deep contrasts. Unlike screenprinting, which relies on stencils and mesh screens to transfer ink, carborundum prints are created by adhering the abrasive powder to the plate surface, which holds ink in varying depths for detailed, tactile effects. This method offers artists the ability to produce prints with a painterly quality and complex surface texture not achievable through conventional screenprinting processes.

Materials and Tools Comparison

Screenprint utilizes a fine mesh screen, stencil, and squeegee to transfer ink onto a substrate, typically requiring polyester or silk screens, plastisol or water-based inks, and specialized cleaning chemicals. Carborundum print relies on an abrasive carborundum grit mixed with adhesive to create textured plates for intaglio printing, involving materials such as copper or zinc plates, carborundum powder, etching needles, and oil-based inks. The tools for screenprinting enable sharp, graphic designs on fabrics and paper, while carborundum prints produce rich, tactile surfaces with varied tonal effects on paper.

Artistic Effects and Visual Qualities

Screenprint produces vibrant, bold colors with crisp edges ideal for graphic designs and sharp contrasts, while Carborundum Print offers rich textures and tactile depth through the use of abrasive Carborundum grit. The artistic effects of Carborundum include subtle gradations and organic, painterly qualities that create a unique, atmospheric look. Visual qualities in Screenprint emphasize flatness and uniformity, contrasting with Carborundum's variable surface texture and nuanced tonal range.

Durability and Longevity of Prints

Screenprint offers high durability with inks that resist fading and wear, making it ideal for long-lasting prints on textiles and surfaces exposed to frequent use. Carborundum print, utilizing abrasive grit mixed with ink, produces textured designs but typically exhibits lower longevity due to the fragile nature of its raised surfaces. For applications demanding extended durability, screenprint remains the preferred choice owing to its robust adhesion and colorfast properties.

Step-by-Step Process: Screenprint vs Carborundum

Screenprint involves creating a stencil on a mesh screen, then forcing ink through the open areas onto the printing surface, layer by layer, allowing precise color application and sharp details. Carborundum print uses a gritty substance mixed with an adhesive applied to a printing plate, creating textured areas that hold ink and produce rich, tactile impressions when pressed onto paper. Both methods require different preparation stages: screenprinting demands screen exposure and stencil creation, while carborundum printing involves coating and drying the plate, with each technique offering unique textural results in the final artwork.

Cost and Accessibility

Screenprint offers a more cost-effective option for artists due to lower equipment and material expenses, making it accessible for beginners and small studios. Carborundum Print involves specialized materials like carborundum grit and requires more advanced techniques, resulting in higher costs and limited accessibility for amateur printmakers. The affordability and ease of setup in screenprinting contribute to its widespread use in both commercial and artistic applications.

Popular Applications and Uses

Screenprint is widely used for vibrant, durable designs on textiles, posters, and packaging due to its versatility in color layering and mass production efficiency. Carborundum print, favored in fine art, creates textured, grainy effects ideal for limited-edition prints and artistic experimentation. Popular applications of screenprint include apparel customization and commercial advertising, while carborundum print excels in creating unique, tactile artworks with rich tonal variations.

Choosing the Right Method for Your Project

Screenprint offers vibrant colors and sharp lines, making it ideal for bold, graphic designs on various materials like fabric and paper. Carborundum print provides rich textures and unique tonal qualities, suited for fine art projects requiring depth and tactile effects. Evaluate factors such as desired visual impact, material compatibility, and production volume to select the best printing technique for your specific project needs.

Screenprint Infographic

libterm.com

libterm.com