Efficiently leveraging paste functionality enhances productivity by allowing you to quickly insert copied content exactly where needed. Understanding various paste options, such as plain text or formatted paste, ensures that your data maintains its intended appearance and structure. Explore the article further to discover tips and tricks that will optimize your paste operations for seamless workflow.

Table of Comparison

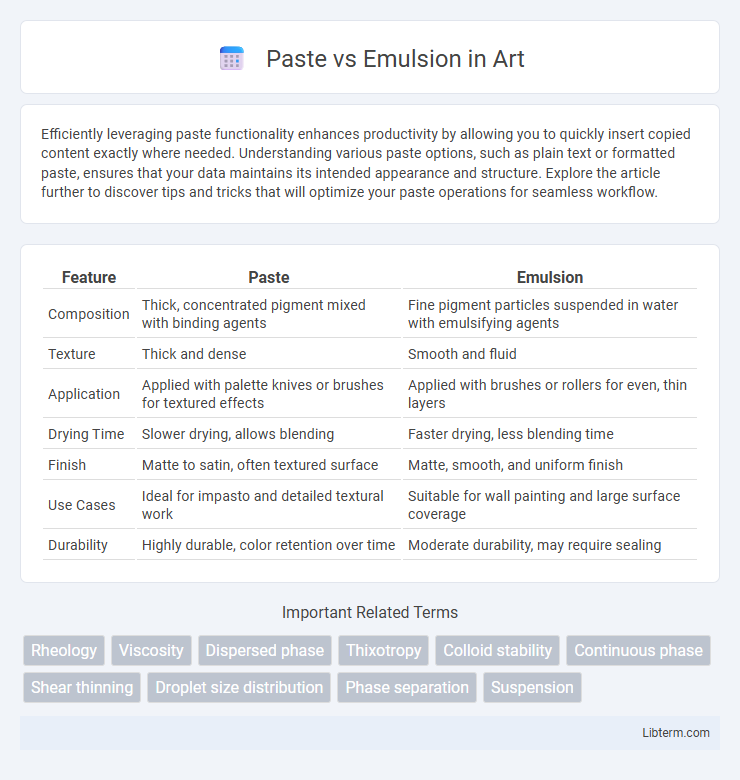

| Feature | Paste | Emulsion |

|---|---|---|

| Composition | Thick, concentrated pigment mixed with binding agents | Fine pigment particles suspended in water with emulsifying agents |

| Texture | Thick and dense | Smooth and fluid |

| Application | Applied with palette knives or brushes for textured effects | Applied with brushes or rollers for even, thin layers |

| Drying Time | Slower drying, allows blending | Faster drying, less blending time |

| Finish | Matte to satin, often textured surface | Matte, smooth, and uniform finish |

| Use Cases | Ideal for impasto and detailed textural work | Suitable for wall painting and large surface coverage |

| Durability | Highly durable, color retention over time | Moderate durability, may require sealing |

Understanding Paste and Emulsion: Key Definitions

Paste refers to a thick, semi-solid substance made by mixing solids with a liquid binder, often used in adhesives, food, and cosmetics for its high viscosity and strong adhesion properties. Emulsion is a heterogeneous mixture of two immiscible liquids, typically oil and water, stabilized by emulsifiers to form a stable blend used extensively in pharmaceuticals, creams, and food products. Understanding the structural differences highlights paste's dense, cohesive texture versus emulsion's dispersed liquid droplets, critical for selecting materials in formulations and applications.

Composition Differences Between Paste and Emulsion

Paste and emulsion differ primarily in their composition and consistency; paste consists of finely ground pigments mixed with a minimal amount of binder, resulting in a thick, dense mixture with low liquid content. Emulsion contains a higher percentage of water or another solvent combined with binders and pigments, creating a fluid consistency that allows for easier application and faster drying times. The binder in paste is more concentrated to hold the solid particles firmly, whereas emulsions rely on surfactants or emulsifying agents to stabilize the dispersion of pigments in the liquid phase.

Common Applications of Paste in Industry

Paste formulations are widely utilized in industries such as adhesives, cosmetics, and food manufacturing due to their thick, viscous texture that enables precise application and strong adhesion. In the construction sector, paste materials are commonly applied as sealants and waterproofing agents, offering durable bonding and flexibility in various substrates. The pharmaceutical industry also employs paste forms for topical drug delivery, ensuring prolonged contact time and controlled release of active ingredients.

Typical Uses of Emulsion Across Sectors

Emulsion finds extensive application in the pharmaceutical industry for targeted drug delivery, enhancing the stability and bioavailability of active ingredients. In the food sector, emulsions improve texture and shelf life in products like sauces, dressings, and dairy alternatives. The cosmetic industry uses emulsions to blend oil and water phases, creating moisturizers and sunscreens that provide smooth application and effective skin hydration.

Physical Properties: Viscosity, Texture, and Stability

Paste formulations typically exhibit higher viscosity, resulting in a thicker and more cohesive texture ideal for applications requiring strong adhesion and minimal flow. Emulsions have lower viscosity, with a smoother, more fluid texture that enhances spreadability and ease of application on various surfaces. Stability-wise, pastes maintain their consistency over time due to dense particle packing, whereas emulsions rely on surfactants for stability, making them more susceptible to phase separation under extreme temperature or mechanical stress.

Preparation Methods: How Pastes and Emulsions Are Made

Pastes are prepared by grinding solid particles into a thick, semi-solid mixture, often using mechanical milling or blending to achieve uniform consistency. Emulsions are created by dispersing one liquid phase into another immiscible liquid, typically stabilized by emulsifying agents and high-shear mixing or homogenization techniques. The preparation of pastes emphasizes particle size reduction and uniform distribution, whereas emulsions require careful control of droplet size and surfactant concentration for stability.

Advantages and Limitations of Pastes

Pastes offer superior adhesion and thicker consistency, making them ideal for applications requiring strong, durable coatings such as in adhesives and dental materials. Their limitation lies in slower drying times and reduced ease of application compared to emulsions, which can hinder efficiency in fast-paced production environments. Despite these drawbacks, pastes excel in providing long-lasting bonds and precise material placement.

Benefits and Challenges of Using Emulsions

Emulsions offer advantages such as improved stability, easier application, and enhanced delivery of active ingredients in various industrial and cosmetic formulations. Challenges include the need for precise formulation to prevent phase separation, sensitivity to temperature and pH changes, and potential for microbial contamination requiring preservatives. Proper emulsifier selection and processing conditions are critical for optimizing emulsion performance and shelf life.

Choosing Between Paste and Emulsion: Critical Factors

Choosing between paste and emulsion depends on factors such as application method, substrate compatibility, and desired finish. Paste formulations generally offer higher viscosity and opacity, ideal for heavy-duty or textured surfaces, while emulsions provide easier application and faster drying times suited for smooth or interior surfaces. Consider environmental conditions, durability requirements, and ease of cleanup to select the most appropriate type for your project.

Innovations and Trends in Paste and Emulsion Technology

Recent innovations in paste and emulsion technology emphasize enhanced stability, improved viscosity control, and eco-friendly formulations to meet industrial and cosmetic demands. Advanced polymer emulsions offer superior film formation and durability, while novel paste technologies incorporate nanomaterials for increased performance and functionality. Trends focus on sustainable raw materials, low-VOC content, and bio-based emulsifiers, driving the development of next-generation products with reduced environmental impact.

Paste Infographic

libterm.com

libterm.com