Plywood is a versatile engineered wood product made from thin layers of wood veneer glued together, providing exceptional strength and durability. Its adaptability makes it ideal for construction, furniture, and interior design applications, offering stability and resistance to warping. Explore the rest of this article to discover how plywood can enhance your projects with its unique properties.

Table of Comparison

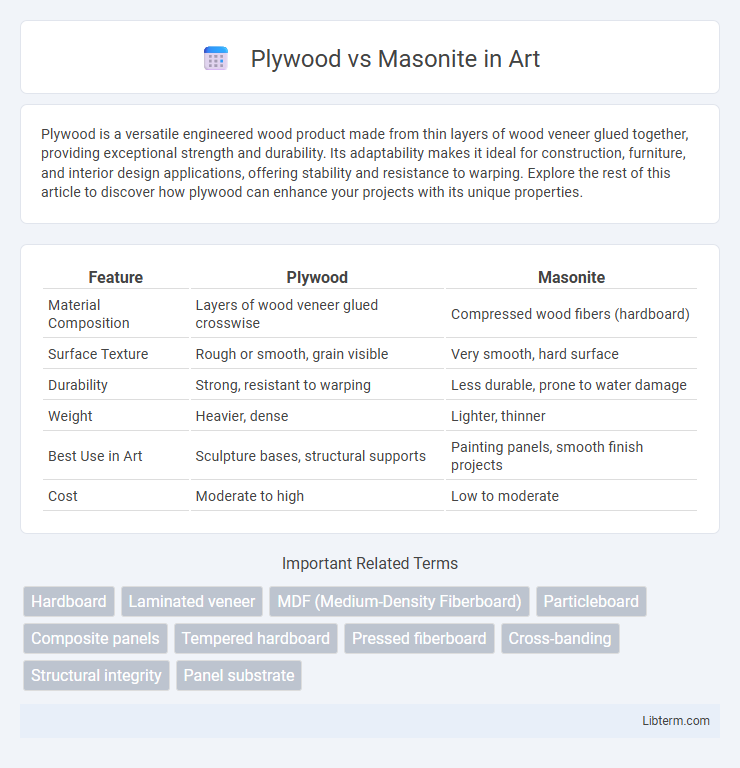

| Feature | Plywood | Masonite |

|---|---|---|

| Material Composition | Layers of wood veneer glued crosswise | Compressed wood fibers (hardboard) |

| Surface Texture | Rough or smooth, grain visible | Very smooth, hard surface |

| Durability | Strong, resistant to warping | Less durable, prone to water damage |

| Weight | Heavier, dense | Lighter, thinner |

| Best Use in Art | Sculpture bases, structural supports | Painting panels, smooth finish projects |

| Cost | Moderate to high | Low to moderate |

Introduction to Plywood and Masonite

Plywood is a versatile engineered wood product composed of thin layers of wood veneer, glued together with adjacent layers having their wood grain rotated up to 90 degrees, enhancing strength and stability. Masonite, also known as hardboard, is a high-density fiberboard made from wood fibers that are steam-cooked and pressure-molded into dense, smooth panels ideal for painting or laminating. Both materials serve distinct purposes in construction and furniture making due to their unique composition and surface characteristics.

Composition and Manufacturing Processes

Plywood consists of multiple layers of wood veneers glued together with each layer's grain rotated for enhanced strength and stability, commonly produced through a hot press method that compresses the veneers under heat and pressure. Masonite, also known as hardboard, is made from wood fibers that are steamed, compressed, and bonded using a wet process called wet-felted or dry-formed manufacturing, resulting in a dense, smooth surface without visible layers. Both materials utilize wood byproducts but differ significantly in structure, with plywood leveraging veneer layering and Masonite focusing on fiber mat densification.

Strength and Durability Comparison

Plywood offers superior strength and durability compared to Masonite due to its layered construction of hardwood veneers glued in alternating grain directions, which provides enhanced resistance to warping, splitting, and delamination. Masonite, made from compressed wood fibers, is less dense and more prone to denting and moisture damage, making it suitable for indoor applications but less reliable for structural use. For projects requiring robust load-bearing capacity and long-term durability, plywood is the preferred material due to its higher impact resistance and dimensional stability.

Weight and Handling Differences

Plywood typically weighs between 30 to 60 pounds per sheet depending on thickness and type, making it heavier but providing greater structural strength compared to Masonite, which is lighter, usually around 25 to 40 pounds per sheet. Masonite, made from compressed wood fibers, offers easier handling and flexibility, ideal for applications requiring lightweight and smooth surfaces. The weight difference impacts transportation and installation, with plywood suited for load-bearing projects and Masonite favored in crafts or interior paneling where lightness and workability are priorities.

Surface Finish and Appearance

Plywood features a natural wood grain surface that can be sanded, stained, or painted to achieve a versatile and attractive finish, making it ideal for visible applications. Masonite, also known as hardboard, offers a smooth, uniform surface with a hard, dense finish that is perfect for painting or laminating but lacks the natural wood texture. The choice between plywood and Masonite hinges on desired aesthetics: plywood presents a rustic or natural appearance, while Masonite provides a sleek, consistent look suitable for modern and industrial designs.

Cost Analysis: Plywood vs Masonite

Plywood typically costs more than Masonite due to its multi-layered wood veneer construction, offering greater strength and durability for structural applications. Masonite, a type of hardboard made from wood fibers, is generally cheaper and used primarily for interior and decorative purposes rather than heavy load-bearing projects. Cost analysis favors Masonite for budget-friendly, surface-level tasks, while plywood's higher price reflects its superior performance in construction and outdoor environments.

Common Uses and Applications

Plywood is commonly used in construction for subflooring, wall and roof sheathing, cabinetry, and furniture due to its strength and durability. Masonite, made from compressed wood fibers, is ideal for interior applications like door skins, paneling, and craft projects because of its smooth surface and ease of painting. Both materials serve distinct purposes: plywood excels in structural support while Masonite is favored for aesthetic finishes and lightweight uses.

Workability and Ease of Installation

Plywood offers superior workability with its layered construction, allowing for easy cutting, nailing, and drilling without chipping or splintering, making it ideal for various applications. Masonite, a type of hardboard, has a smooth surface but is denser and more brittle, which can complicate cutting and handling during installation. While plywood's structural strength supports straightforward fastening and molding, Masonite requires careful handling and pre-drilling to avoid cracking, impacting ease of installation.

Environmental Impact and Sustainability

Plywood and Masonite differ significantly in environmental impact, with plywood generally considered more sustainable due to its layered wood veneer construction from renewable timber sources and lower formaldehyde emissions compared to Masonite, which is made from compressed wood fibers often bonded with synthetic resins. Masonite production can involve higher energy consumption and emits more volatile organic compounds (VOCs), raising concerns about indoor air quality and ecological footprint. Choosing certified plywood with sustainable forestry credentials supports better environmental stewardship and resource renewal.

Choosing the Right Material for Your Project

Plywood offers superior strength and moisture resistance, making it ideal for structural projects and outdoor applications, while Masonite provides a smooth, dense surface perfect for interior paneling, cabinets, and decorative finishes. Consider the project's durability requirements, exposure to elements, and surface finish needs when choosing between plywood and Masonite. Budget and ease of installation also influence the decision, with Masonite typically being more affordable but less durable than plywood.

Plywood Infographic

libterm.com

libterm.com