Screenprinting offers vibrant, durable designs on various materials by pushing ink through a mesh stencil onto fabric or paper. This versatile printing technique is popular for custom apparel, promotional items, and artistic projects. Discover how screenprinting can elevate Your creative ventures by exploring the rest of this article.

Table of Comparison

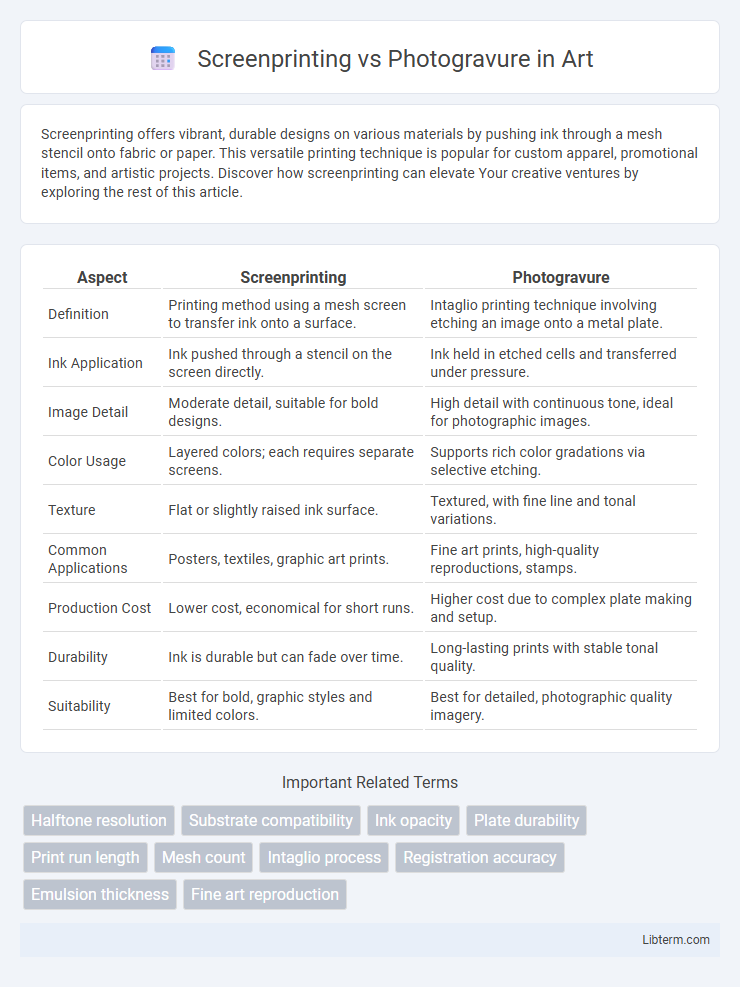

| Aspect | Screenprinting | Photogravure |

|---|---|---|

| Definition | Printing method using a mesh screen to transfer ink onto a surface. | Intaglio printing technique involving etching an image onto a metal plate. |

| Ink Application | Ink pushed through a stencil on the screen directly. | Ink held in etched cells and transferred under pressure. |

| Image Detail | Moderate detail, suitable for bold designs. | High detail with continuous tone, ideal for photographic images. |

| Color Usage | Layered colors; each requires separate screens. | Supports rich color gradations via selective etching. |

| Texture | Flat or slightly raised ink surface. | Textured, with fine line and tonal variations. |

| Common Applications | Posters, textiles, graphic art prints. | Fine art prints, high-quality reproductions, stamps. |

| Production Cost | Lower cost, economical for short runs. | Higher cost due to complex plate making and setup. |

| Durability | Ink is durable but can fade over time. | Long-lasting prints with stable tonal quality. |

| Suitability | Best for bold, graphic styles and limited colors. | Best for detailed, photographic quality imagery. |

Introduction to Screenprinting and Photogravure

Screenprinting utilizes a mesh stencil to transfer ink onto a substrate, producing vibrant, precise designs ideal for textiles, posters, and packaging. Photogravure employs a photochemical etching process to create finely detailed, continuous-tone images on metal plates, commonly used in high-quality art printing and currency production. Both techniques offer unique advantages in color richness and detail depending on the application requirements.

Historical Background of Each Printing Technique

Screenprinting emerged in the early 20th century, gaining popularity for its versatility and vibrant color reproduction, widely used in commercial and artistic applications. Photogravure, developed in the 19th century, is a photo-mechanical process that reproduces photographic images with fine detail and tonal range, often employed for high-quality book illustrations and art prints. Both techniques reflect distinct technological advancements in printmaking, with screenprinting emphasizing stencil-based ink application and photogravure utilizing etched copper plates to achieve detailed image transfer.

Core Processes: How Screenprinting Works

Screenprinting involves creating a stencil, or screen, where ink is pushed through mesh openings onto the printing surface, allowing for vibrant colors and sharp designs. The process uses a squeegee to evenly distribute ink across the screen, ensuring consistent coverage and opacity. This method is ideal for bold and graphic prints, offering durability and vividness unmatched by photogravure.

Core Processes: How Photogravure Works

Photogravure utilizes a copper plate etched with a photographic image through a chemical process that transfers tonal variations directly onto the printing surface. This method allows for continuous-tone reproduction by varying the depth of the etching, capturing intricate details and subtle gradations with high precision. The plate is then inked and pressed onto paper, producing rich, high-quality prints ideal for fine art and high-resolution image reproduction.

Image Quality and Print Resolution Comparison

Photogravure offers superior image quality with exceptional detail and tonal range, producing continuous-tone prints ideal for high-resolution photographic reproductions. Screenprinting, while versatile and vibrant, typically delivers lower resolution with fewer gradations, making it better suited for bold graphics and solid colors rather than fine detail. The photogravure process achieves print resolutions often exceeding 300 lines per inch, whereas screenprinting resolutions generally max out around 150 lines per inch, impacting the sharpness and clarity of the final image.

Material Compatibility and Versatility

Screenprinting excels in material compatibility, effectively printing on textiles, plastics, glass, and metals, making it highly versatile for diverse applications. Photogravure specializes in high-resolution image reproduction on paper and flexible packaging films but is limited in printing on rigid or textured surfaces. Both techniques offer unique advantages, with screenprinting providing broader substrate adaptability and photogravure delivering superior detail for printed media.

Production Speed and Volume Capabilities

Screenprinting offers fast production speeds and excels in high-volume runs, making it ideal for large orders with consistent designs. Photogravure provides superior image detail but operates at slower speeds, suitable for moderate to large volumes where quality takes precedence over rapid output. Manufacturers choose screenprinting for efficiency in mass production, while photogravure fits complex, high-quality print demands despite lower throughput.

Cost Analysis: Setup and Operational Expenses

Screenprinting involves lower initial setup costs, typically ranging from $500 to $3,000 depending on equipment complexity, while photogravure requires high capital investment often exceeding $50,000 due to expensive engraving and cylinder-making processes. Operational expenses for screenprinting include ink, screens, and labor, which are relatively economical, whereas photogravure demands costly maintenance, specialized materials, and higher energy consumption, increasing per-unit production costs. For small to medium print runs, screenprinting offers cost-effective scalability, whereas photogravure suits large-volume projects where higher upfront costs are offset by lower unit prices.

Environmental Impact and Sustainability

Screenprinting often uses plastisol inks containing PVC and phthalates, which can release harmful chemicals into the environment if not disposed of properly. Photogravure, relying on metal plates and chemical processes, generates significant chemical waste, including solvents and acids, posing challenges for waste management and soil contamination. Sustainable alternatives in both methods include water-based inks for screenprinting and improved chemical recycling systems for photogravure to reduce environmental footprints.

Choosing the Right Technique: Applications and Recommendations

Screenprinting offers vibrant color reproduction and durability, ideal for bold graphics on textiles, posters, and packaging, while photogravure excels in high-resolution image quality for detailed photographic prints and fine art reproductions. For large runs requiring consistent color and texture, photogravure provides superior precision, whereas screenprinting suits smaller batches or custom designs with variable ink effects. Selecting the right technique depends on project scale, image detail, and substrate compatibility, ensuring optimal print quality and cost-efficiency.

Screenprinting Infographic

libterm.com

libterm.com