In-house production offers businesses full control over the manufacturing process, ensuring higher quality and faster turnaround times. By managing production internally, companies can reduce costs and customize products to meet specific customer needs. Discover how in-house production can transform your operations by reading the rest of the article.

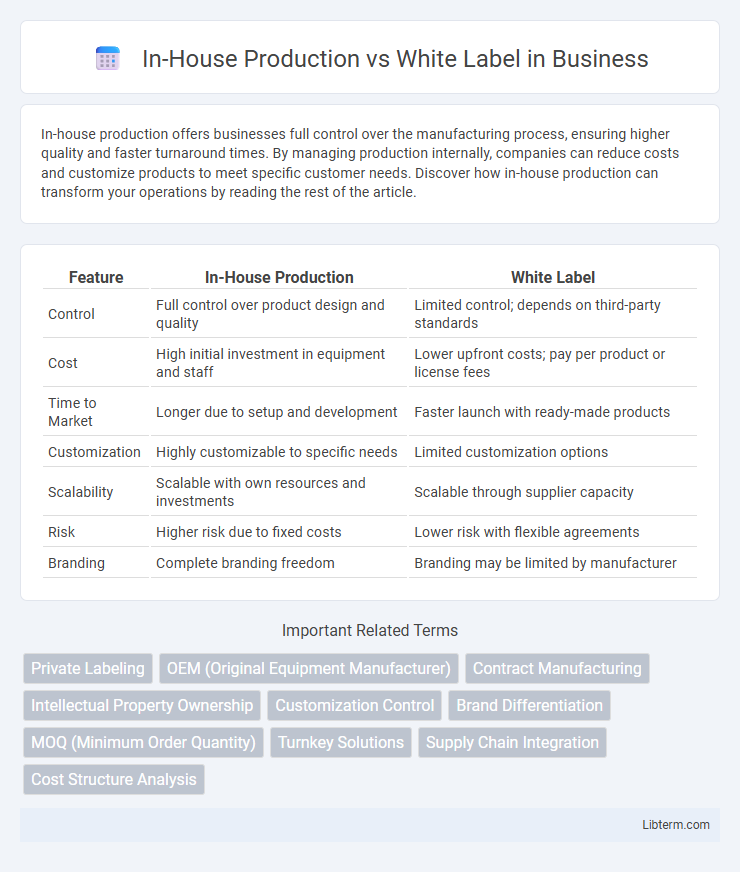

Table of Comparison

| Feature | In-House Production | White Label |

|---|---|---|

| Control | Full control over product design and quality | Limited control; depends on third-party standards |

| Cost | High initial investment in equipment and staff | Lower upfront costs; pay per product or license fees |

| Time to Market | Longer due to setup and development | Faster launch with ready-made products |

| Customization | Highly customizable to specific needs | Limited customization options |

| Scalability | Scalable with own resources and investments | Scalable through supplier capacity |

| Risk | Higher risk due to fixed costs | Lower risk with flexible agreements |

| Branding | Complete branding freedom | Branding may be limited by manufacturer |

Introduction to In-House Production and White Label

In-house production involves creating products internally within a company's own facilities, allowing full control over quality, customization, and production timelines. White label production entails outsourcing manufacturing to third-party companies that produce generic products branded under the client's name, enabling faster market entry and cost savings. Choosing between in-house and white label production depends on factors such as budget, expertise, production capacity, and brand control priorities.

Core Definitions: In-House Production vs White Label

In-house production refers to the process where a company manufactures its products internally, maintaining direct control over quality, design, and production timelines. White label involves outsourcing product manufacturing to a third party, which produces generic items rebranded and sold under the retailer's name. Choosing in-house production enhances brand uniqueness and customization, while white label offers cost-efficiency and faster market entry.

Cost Analysis: Budget Impact Comparison

In-house production typically incurs higher upfront costs due to expenses related to equipment, labor, and facility maintenance, but it offers greater control over quality and customization. White label solutions reduce initial investment by outsourcing manufacturing and leveraging existing products, which can lower overall expenses and accelerate market entry. Evaluating budget impact involves comparing fixed and variable costs for in-house setups against scalable, pay-per-unit pricing models of white label partners.

Speed to Market: Time Efficiency Differences

In-house production often requires longer lead times due to internal resource allocation, complex workflows, and the need for quality control, impacting speed to market. White label solutions provide faster time efficiency by leveraging pre-existing products and streamlined processes, enabling quicker product launch and market entry. Companies prioritize time to market differently based on production control preferences and the urgency of capturing market opportunities.

Quality Control and Customization Options

In-house production offers superior quality control by enabling direct oversight of materials, processes, and standards, ensuring consistent product excellence tailored to brand specifications. White label solutions provide faster time-to-market with pre-made products but often limit customization options and reduce control over manufacturing details. Brands prioritizing unique designs and stringent quality standards typically benefit more from in-house production than from white label partnerships.

Scalability and Flexibility in Business Growth

In-house production offers greater control and customization, enabling businesses to rapidly adapt and scale operations according to specific needs, which enhances flexibility in growth strategies. White label solutions provide faster market entry with reduced initial investment, but may limit scalability due to dependency on third-party manufacturers and less ability to tailor products. Companies aiming for long-term growth should evaluate the trade-offs between in-house agility and white label convenience to optimize scalability and flexibility.

Brand Identity and Intellectual Property Considerations

In-house production ensures full control over brand identity and intellectual property, allowing companies to maintain unique product designs and proprietary technologies without risk of duplication. White label production can dilute brand identity since products are often sold under multiple brand names, limiting exclusivity and complicating intellectual property enforcement. Protecting trademarks and patents is more straightforward with in-house manufacturing, where confidential processes and innovations remain internal, reducing potential infringement risks.

Risk Management and Reliability Factors

In-house production offers greater control over quality and timelines, reducing risks related to product consistency and intellectual property breaches. White label solutions mitigate operational risks by leveraging established manufacturers' expertise but introduce dependencies on external partners, impacting supply chain reliability. Evaluating vendor track records, contract terms, and production transparency is essential to manage reliability and minimize potential disruptions.

Ideal Scenarios for Each Production Method

In-house production is ideal for companies seeking full control over product quality, customization, and brand differentiation, particularly in industries where proprietary processes or sensitive data are involved. White label production suits businesses aiming to quickly expand product lines or enter new markets without significant R&D investment, leveraging established manufacturing expertise and economies of scale. Choosing between these methods depends on factors like budget, timeline, product complexity, and strategic goals for branding and innovation.

Conclusion: Choosing the Right Model for Your Business

Selecting the right production model depends on your business goals, budget, and desired control over the product. In-house production offers greater customization and quality oversight but requires higher investment and resources, while white label solutions provide faster market entry and lower upfront costs with limited brand differentiation. Evaluating your company's capacity and long-term strategy ensures a choice that maximizes efficiency and aligns with your growth objectives.

In-House Production Infographic

libterm.com

libterm.com