Volatilization refers to the process by which liquids or solids convert into vapor and release into the atmosphere, impacting environmental quality and air pollution levels. Understanding volatilization helps in assessing the fate of chemicals in soil and water, guiding effective pollution control strategies. Explore the rest of the article to learn how volatilization affects your environment and what measures can mitigate its impact.

Table of Comparison

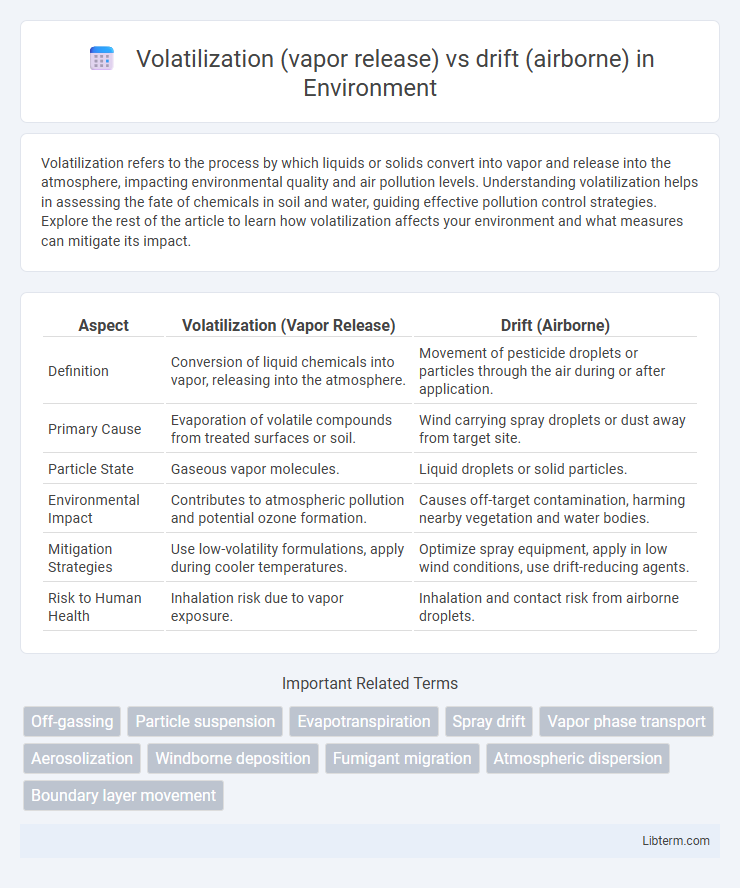

| Aspect | Volatilization (Vapor Release) | Drift (Airborne) |

|---|---|---|

| Definition | Conversion of liquid chemicals into vapor, releasing into the atmosphere. | Movement of pesticide droplets or particles through the air during or after application. |

| Primary Cause | Evaporation of volatile compounds from treated surfaces or soil. | Wind carrying spray droplets or dust away from target site. |

| Particle State | Gaseous vapor molecules. | Liquid droplets or solid particles. |

| Environmental Impact | Contributes to atmospheric pollution and potential ozone formation. | Causes off-target contamination, harming nearby vegetation and water bodies. |

| Mitigation Strategies | Use low-volatility formulations, apply during cooler temperatures. | Optimize spray equipment, apply in low wind conditions, use drift-reducing agents. |

| Risk to Human Health | Inhalation risk due to vapor exposure. | Inhalation and contact risk from airborne droplets. |

Understanding Volatilization: Definition and Mechanisms

Volatilization refers to the process where a liquid or solid chemical transforms into a vapor and is released into the atmosphere, primarily influenced by temperature, chemical properties, and environmental conditions. This vapor release differs from drift, which involves the physical movement of airborne pesticide droplets or particles during or shortly after application. Understanding volatilization mechanisms includes studying evaporation rates, vapor pressure, and interactions with soil and plant surfaces to predict atmospheric dispersal and potential non-target exposure.

What is Drift? Exploring Airborne Movement

Drift refers to the airborne movement of pesticide droplets or particles during or shortly after application, posing risks of off-target contamination. Unlike volatilization, which involves the transformation of pesticides from liquid or solid state to vapor, drift is primarily the physical displacement of particles by wind or air currents. Understanding drift is critical for implementing effective application techniques to minimize environmental impact and protect surrounding ecosystems.

Key Differences Between Volatilization and Drift

Volatilization involves the transformation of a substance from liquid or solid form into vapor, releasing it into the atmosphere primarily due to temperature and chemical properties. Drift refers to the physical movement of sprayed droplets or particles through the air to non-target sites during application, influenced by wind speed, droplet size, and spray technique. Key differences include volatilization being a phase change process causing vapor release over time, while drift is immediate physical displacement of particles, affecting spray accuracy and environmental contamination.

Factors Influencing Volatilization Rates

Volatilization rates depend significantly on temperature, with higher temperatures increasing vapor pressure and accelerating chemical release into the atmosphere. Wind speed influences the dispersion of vapors, enhancing volatilization by removing saturated air near the surface. Soil moisture and organic matter content also regulate volatilization by affecting chemical adsorption and evaporation dynamics.

Environmental Conditions Impacting Drift

Volatilization and drift are distinct processes influencing pesticide distribution, where volatilization involves vapor release from treated surfaces and drift refers to airborne movement of spray droplets or particles. Environmental conditions such as temperature, humidity, wind speed, and atmospheric stability critically impact drift, with higher temperatures and wind speeds increasing evaporation rates and extending the drift potential. Low humidity enhances volatilization by accelerating pesticide vaporization, while unstable atmospheric conditions promote turbulent air mixing, facilitating farther drift distances.

Pesticide Formulation and Its Role in Vapor Release

Pesticide formulation significantly influences volatilization rates, with solvent-based and emulsifiable concentrate formulations typically exhibiting higher vapor release compared to granular or wettable powder types. Formulations containing volatile organic compounds (VOCs) increase the likelihood of pesticide molecules transitioning into the vapor phase, enhancing potential for off-target movement through vapor drift. Optimizing formulation chemistry, such as incorporating microencapsulation or adjuvants, can reduce volatilization and subsequent airborne drift, improving application efficacy and environmental safety.

Monitoring and Measuring Airborne Pesticide Movement

Monitoring and measuring airborne pesticide movement requires precise differentiation between volatilization and drift mechanisms to implement effective control strategies. Volatilization involves pesticide vapor release from treated surfaces, necessitating real-time gas chromatography and photoionization detectors for accurate airborne concentration measurement. Drift monitoring leverages high-volume air samplers and particle analyzers to capture solid and liquid pesticide droplets, enabling assessment of off-target transport and exposure risks.

Strategies to Minimize Volatilization

Minimizing volatilization involves applying pesticides under optimal environmental conditions, such as low temperatures and low wind speeds, to reduce vapor release into the atmosphere. Using formulations with lower vapor pressure, incorporating chemicals into the soil, and avoiding application before rain or irrigation also significantly decrease volatilization losses. Employing drift reduction technologies like low-drift nozzles and buffer zones further limits both volatilization and subsequent airborne movement.

Best Practices to Reduce Drift

Volatilization involves the transformation of pesticides from liquid or solid form into vapor, leading to potential diffusion beyond the target area, while drift refers specifically to the airborne movement of pesticide droplets or particles during or immediately after application. Best practices to reduce drift include applying pesticides under low wind speeds (less than 10 mph), using larger droplet sizes through appropriate nozzles, and avoiding application near sensitive areas or water bodies. Implementing buffer zones, calibrating equipment regularly, and adopting precision application technologies further minimize off-target contamination and environmental impact.

Regulatory Guidelines Addressing Volatilization and Drift

Regulatory guidelines addressing volatilization and drift primarily focus on minimizing airborne pesticide exposure to protect human health and the environment. Agencies like the EPA have established application restrictions, buffer zones, and weather condition requirements to limit vapor release and off-target movement during pesticide use. Compliance with labeling instructions and adopting best management practices are critical to reducing volatilization-related drift incidents under existing regulatory frameworks.

Volatilization (vapor release) Infographic

libterm.com

libterm.com