Slumping occurs when materials such as ceramics or glass soften and deform under heat, causing changes in shape or texture during manufacturing processes. Understanding the temperature thresholds and techniques to control slumping is essential for achieving desired product quality and structural integrity. Explore the full article to learn how to manage slumping effectively in your projects.

Table of Comparison

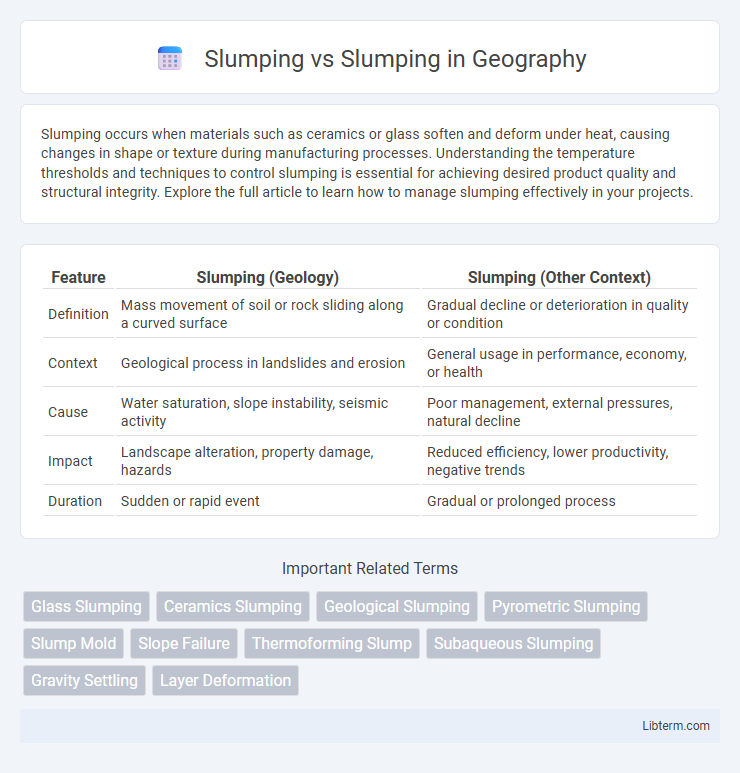

| Feature | Slumping (Geology) | Slumping (Other Context) |

|---|---|---|

| Definition | Mass movement of soil or rock sliding along a curved surface | Gradual decline or deterioration in quality or condition |

| Context | Geological process in landslides and erosion | General usage in performance, economy, or health |

| Cause | Water saturation, slope instability, seismic activity | Poor management, external pressures, natural decline |

| Impact | Landscape alteration, property damage, hazards | Reduced efficiency, lower productivity, negative trends |

| Duration | Sudden or rapid event | Gradual or prolonged process |

Introduction to Slumping vs Slumping

Slumping in ceramics refers to the process where glass or clay softens under heat, allowing it to mold into a desired shape over a slump mold, characterized by controlled deformation. Conversely, slumping can also denote structural failure in materials or objects, where excessive bending leads to permanent deformation or collapse. Understanding the distinction between artistic slumping techniques and the mechanical concept of slumping is critical for materials science and pottery design applications.

Defining “Slumping” in Different Contexts

Slumping refers to a geological process where loose soil or rock moves downward along a curved surface, causing slope failure and landslides in earth science. In glassmaking, slumping describes the technique of heating glass until it softens and conforms to a mold's shape without melting completely. Both contexts emphasize deformation, but the term's meaning shifts from natural ground movement to controlled shaping of materials.

Common Causes of Slumping

Slumping commonly occurs due to moisture absorption, improper drying processes, or weak structural integrity in clay or ceramic materials. Industrial slumping often results from inconsistent heating rates or uneven temperature distribution in kilns or molds. Identifying specific causes like material composition and environmental conditions is crucial to prevent defects and ensure quality.

Physical Effects of Slumping

Slumping in glassmaking results in permanent deformation due to heat softening the material, causing gravity to reshape the glass over a mold, which enhances three-dimensional design features. In contrast, slumping in ceramics involves the controlled softening of clay pieces to form specific shapes without complete melting, preserving structural integrity. Both processes influence physical properties such as thickness variation, texture smoothing, and dimensional stability, essential for functional and aesthetic outcomes.

Psychological Impact of Slumping

Slumping, characterized by a poor, collapsed posture, significantly affects psychological well-being by increasing feelings of fatigue, stress, and decreased self-confidence. Research shows that maintaining an upright posture can reduce symptoms of depression and improve mood, while slumping is linked to heightened cortisol levels and anxiety. Addressing slumping through posture correction techniques enhances not only physical health but also mental resilience and emotional stability.

Indicators and Signs of Slumping

Slumping is characterized by visible cracks, surface deformation, and irregular sediment layers indicating material loss and structural instability. Indicators include subsidence areas, sagging ground, tilted trees, and displaced fences reflecting ground movement. Signs such as tension cracks and disrupted vegetation patterns serve as early warnings of ongoing slumping processes.

Slumping in Sports Performance

Slumping in sports performance refers to a sudden decline in an athlete's effectiveness, often characterized by reduced accuracy, speed, or overall output. This decline can result from physical fatigue, mental stress, or technical errors, significantly impacting game outcomes and team dynamics. Understanding the causes and recovery strategies for slumping is essential for coaches and athletes aiming to restore peak performance levels quickly.

Strategies for Overcoming Slumping

Effective strategies for overcoming slumping in sports or productivity include setting specific, achievable goals and maintaining a consistent routine to rebuild confidence and performance. Incorporating mental training techniques such as visualization and mindfulness helps reduce anxiety and promotes focus during periods of decline. Regular performance analysis and seeking feedback from coaches or peers enable targeted adjustments, fostering gradual improvement and resilience.

Comparing Slumping with Similar Phenomena

Slumping is a type of mass wasting where a coherent block of soil or rock moves downslope along a curved surface, differing from landslides that typically involve rapid, fragmented debris flow. Unlike soil creep, which is a slow, gradual deformation of soil layers without distinct movement planes, slumping involves more abrupt displacement and rotational movement. Rockfalls contrast with slumping by involving free-falling rock fragments rather than the rotational sliding characteristic of slumps.

Summary: Key Takeaways on Slumping

Slumping is a glass-forming technique where heated glass is shaped by gravity over a mold, creating smooth, curved forms ideal for artistic and functional pieces. Key takeaways include its advantages like precision in shape control, versatility with different glass types, and suitability for producing both simple and complex designs. Differences from other methods, such as casting or bending, highlight slumping's cost-efficiency and lower temperature requirements, making it a popular choice in glass art and manufacturing.

Slumping Infographic

libterm.com

libterm.com