Homogeneous materials consist of uniform components that exhibit consistent properties throughout their structure, ensuring predictability in performance and behavior. This uniformity plays a crucial role in industries like manufacturing, material science, and pharmaceuticals, where consistency is key. Explore the article to understand how homogeneity impacts various applications and why it matters to your projects.

Table of Comparison

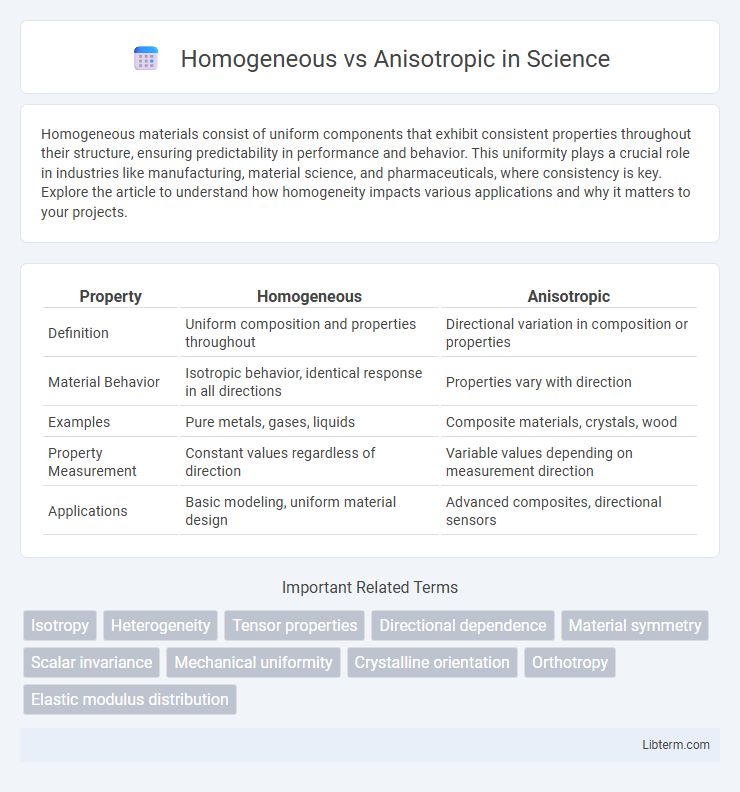

| Property | Homogeneous | Anisotropic |

|---|---|---|

| Definition | Uniform composition and properties throughout | Directional variation in composition or properties |

| Material Behavior | Isotropic behavior, identical response in all directions | Properties vary with direction |

| Examples | Pure metals, gases, liquids | Composite materials, crystals, wood |

| Property Measurement | Constant values regardless of direction | Variable values depending on measurement direction |

| Applications | Basic modeling, uniform material design | Advanced composites, directional sensors |

Understanding Homogeneous Materials

Homogeneous materials exhibit uniform composition and properties throughout their volume, ensuring consistent behavior under mechanical, thermal, or electrical stresses. These materials lack internal variations, resulting in isotropic characteristics where properties remain identical in all directions. Understanding homogeneous materials is crucial for applications requiring predictable and reliable performance, such as in structural engineering and manufacturing of composites.

Defining Anisotropic Materials

Anisotropic materials exhibit different physical properties depending on the direction of measurement, unlike homogeneous materials which have uniform properties throughout. This directional dependence arises from the internal structure, such as grain orientation in crystals or fiber alignment in composites. Common examples of anisotropic materials include wood, which is stronger along the grain, and layered composites used in aerospace applications.

Key Differences Between Homogeneous and Anisotropic

Homogeneous materials exhibit uniform properties throughout their structure, meaning physical characteristics such as strength, conductivity, and elasticity remain consistent regardless of the measurement direction. Anisotropic materials display direction-dependent properties, causing variations in behavior like thermal expansion, electrical resistance, or mechanical strength based on orientation. Understanding the key difference lies in uniformity: homogeneous materials maintain consistent attributes in all directions, while anisotropic materials vary, which is critical in fields like materials science, engineering, and geophysics.

Material Structure and Uniformity

Homogeneous materials exhibit uniform structure and properties throughout their volume, ensuring consistent mechanical behavior and predictable performance in applications. Anisotropic materials possess direction-dependent properties due to variations in their internal structure, such as grain orientation or fiber alignment, leading to uneven strength and deformation characteristics. Understanding the distinction between homogeneous and anisotropic material structures is crucial for selecting materials in engineering and manufacturing processes where uniformity or directional strength is required.

Mechanical Properties Comparison

Homogeneous materials exhibit uniform mechanical properties throughout their volume, resulting in consistent strength, elasticity, and toughness regardless of direction. Anisotropic materials display direction-dependent mechanical properties, with variations in tensile strength, stiffness, and ductility depending on the orientation of the applied force. This directional dependence in anisotropic materials, such as composites or single crystals, enables tailored performance for specific applications where mechanical behavior varies with loading direction.

Applications in Engineering and Design

Homogeneous materials exhibit uniform properties throughout, making them ideal for applications requiring consistent mechanical strength and predictable performance, such as in structural components and aerospace engineering. Anisotropic materials, with direction-dependent properties, are crucial in advanced design fields like composite materials, where tailored strength and stiffness optimize performance in automotive and civil engineering. Engineering applications leverage anisotropy in materials like carbon fiber and wood to enhance durability, reduce weight, and improve functionality in complex load-bearing structures.

Impact on Material Performance

Homogeneous materials exhibit uniform properties throughout, ensuring consistent mechanical strength, thermal conductivity, and electrical behavior, which simplifies design and predicts performance reliably. Anisotropic materials possess direction-dependent characteristics that enhance specific performance aspects, such as higher tensile strength or thermal resistance along particular axes, enabling tailored applications in aerospace, electronics, and composites. The impact on material performance is critical in selecting materials for structural integrity, heat management, and functionality under varying stress conditions, with anisotropy offering advantages in optimizing efficiency and durability for specialized uses.

Testing and Identification Methods

Testing and identification methods for homogeneous materials typically involve uniform property measurements such as tensile strength or thermal conductivity across multiple sample points to confirm consistency. In contrast, anisotropic materials require directional testing like ultrasound velocity or X-ray diffraction at various orientations to determine property variations linked to structural anisotropy. Advanced techniques such as polarized light microscopy and electron backscatter diffraction provide high-resolution identification of anisotropic textures and grain orientations essential for accurate material characterization.

Advantages and Limitations of Each Type

Homogeneous materials offer uniform properties throughout, ensuring predictable performance and ease of manufacturing, but they may lack specialized characteristics needed for advanced applications. Anisotropic materials provide directional strength, thermal conductivity, or electrical properties tailored to specific needs, enhancing performance in targeted uses yet complicating fabrication and design due to their variability. Selecting between homogeneous and anisotropic materials depends on balancing simplicity and consistency against customized functionality and complexity.

Choosing the Right Material: Homogeneous or Anisotropic?

Choosing the right material between homogeneous and anisotropic depends on the application's performance requirements and environmental conditions. Homogeneous materials exhibit uniform properties in all directions, making them ideal for consistent strength and predictable behavior. Anisotropic materials offer direction-dependent properties, providing enhanced strength, stiffness, or conductivity along specific orientations, crucial for advanced engineering applications like aerospace composites or electronic devices.

Homogeneous Infographic

libterm.com

libterm.com