Plastic offers versatile applications across industries due to its durability, lightweight nature, and cost-effectiveness. Innovations in biodegradable and recycled plastics address environmental concerns while maintaining functionality. Explore the rest of the article to understand how plastic impacts your daily life and sustainable alternatives.

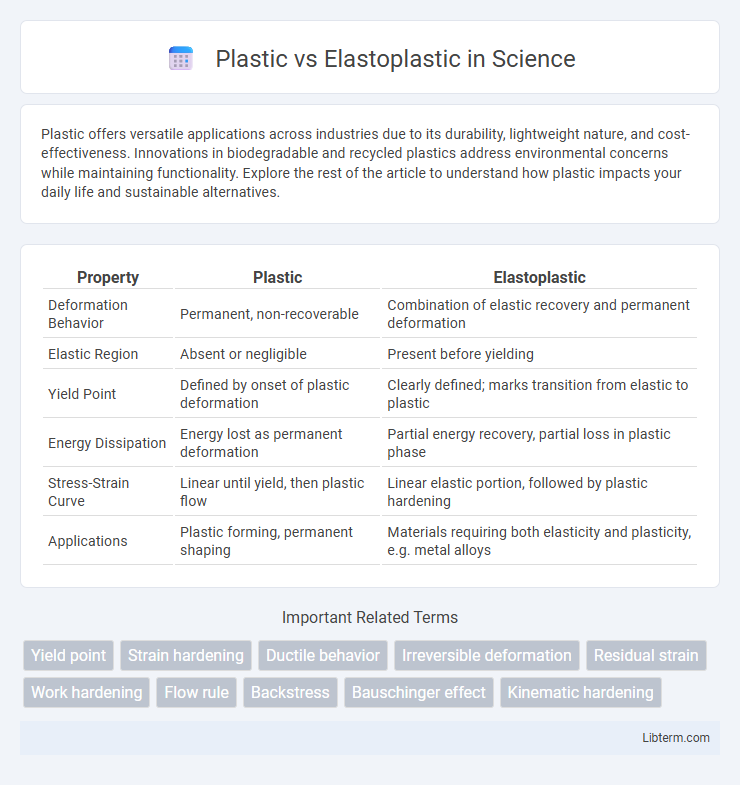

Table of Comparison

| Property | Plastic | Elastoplastic |

|---|---|---|

| Deformation Behavior | Permanent, non-recoverable | Combination of elastic recovery and permanent deformation |

| Elastic Region | Absent or negligible | Present before yielding |

| Yield Point | Defined by onset of plastic deformation | Clearly defined; marks transition from elastic to plastic |

| Energy Dissipation | Energy lost as permanent deformation | Partial energy recovery, partial loss in plastic phase |

| Stress-Strain Curve | Linear until yield, then plastic flow | Linear elastic portion, followed by plastic hardening |

| Applications | Plastic forming, permanent shaping | Materials requiring both elasticity and plasticity, e.g. metal alloys |

Introduction to Plastic and Elastoplastic Materials

Plastic materials exhibit permanent deformation under applied stress without returning to their original shape, characterized by a linear elastic region followed by irreversible strain. Elastoplastic materials combine elastic and plastic behavior, initially deforming elastically and recovering their shape upon unloading until a yield point is exceeded, which leads to permanent deformation. Understanding the stress-strain relationship in these materials is crucial for applications in structural engineering, manufacturing, and material science.

Defining Plastic Behavior: Key Characteristics

Plastic behavior in materials refers to permanent deformation that occurs when stress surpasses the elastic limit, causing a material to undergo irreversible shape change. Elastoplastic materials exhibit both elastic and plastic characteristics, initially deforming elastically under low stress and then plastically once the yield point is exceeded. Key distinctions include the presence of a well-defined yield stress in elastoplastic materials and the absence of recovery after removing stress in purely plastic behavior.

Understanding Elastoplasticity: Fundamental Concepts

Elastoplasticity describes materials that exhibit both elastic behavior, where deformation is reversible, and plastic behavior, where permanent deformation occurs after surpassing the yield point. Unlike purely plastic materials that deform permanently under stress, elastoplastic materials initially respond elastically and only yield plastically once the applied stress exceeds a critical threshold defined by the yield stress. This dual response is critical in engineering applications for accurately predicting material performance under varying load conditions and ensuring structural integrity.

Stress-Strain Relationships in Plastics vs. Elastoplastics

Stress-strain relationships in plastics exhibit irreversible deformation beyond the yield point, characterized by permanent plastic flow without significant elastic recovery, while elastoplastics combine initial elastic behavior with subsequent plastic deformation, resulting in partial strain recovery upon unloading. Plastics typically show a clear yield stress followed by strain hardening or softening, whereas elastoplastics demonstrate a nonlinear elastic region preceding plastic yielding, allowing for energy dissipation and resilience under cyclic loading. The distinction in their mechanical response is critical for applications requiring durability under repeated stress, with elastoplastics providing enhanced toughness due to their hybrid stress-strain characteristics.

Material Properties: Comparing Yield and Hardening

Plastic materials exhibit a distinct yield point where they deform permanently without any additional stress, while elastoplastic materials show an initial elastic region followed by plastic deformation beyond the yield stress. Elastoplastic behavior incorporates strain hardening, enabling the material to sustain increased stress after yielding, contrasting with perfectly plastic materials that exhibit no hardening. Yield strength and strain hardening modulus are critical parameters distinguishing plastic from elastoplastic materials in engineering applications.

Typical Applications of Plastic Materials

Plastic materials are widely used in packaging, automotive parts, consumer goods, and construction due to their lightweight, durability, and cost-effectiveness. Common applications include polyethylene films for packaging, polypropylene components in automotive interiors, and PVC pipes in plumbing systems. These materials offer excellent chemical resistance and ease of fabrication, making them ideal for mass production in diverse industries.

Common Uses of Elastoplastic Materials

Elastoplastic materials combine the elastic properties of rubber with the plasticity of thermoplastics, making them ideal for applications requiring both flexibility and durability. Common uses include automotive parts such as bumpers and interior components, medical devices like flexible tubing and prosthetics, and consumer goods including footwear soles and sports equipment. Their ability to absorb impact while maintaining shape under stress enhances performance in these sectors.

Advantages and Limitations of Plastic Materials

Plastic materials offer advantages such as lightweight properties, corrosion resistance, and ease of manufacturing through molding and extrusion processes. Their limitations include lower mechanical strength compared to metals, susceptibility to UV degradation, and challenges with thermal stability at high temperatures. Elastoplastic materials combine elastic and plastic deformation characteristics, providing improved durability and resistance to permanent deformation under stress, but often at higher costs and more complex processing requirements.

Benefits and Drawbacks of Elastoplastic Behavior

Elastoplastic materials exhibit both elastic and plastic deformation, allowing them to absorb energy through reversible and permanent shape changes, which enhances durability in structural applications. This behavior improves material resilience by preventing sudden failure under high stress, making elastoplastic materials ideal for load-bearing components. However, the drawback lies in the permanent deformation that accumulates over time, potentially compromising structural integrity and requiring careful design to manage fatigue and maintain safety.

Selecting the Right Material: Plastic or Elastoplastic?

Selecting the right material between plastic and elastoplastic depends on the application's flexibility and durability requirements. Plastics offer rigidity and easy molding, ideal for structural components, while elastoplastics provide superior elasticity and impact resistance, making them suitable for products requiring repeated deformation. Understanding stress-strain behavior and environmental exposure guides optimal material choice for performance and longevity.

Plastic Infographic

libterm.com

libterm.com