Viscoplastic materials exhibit both viscous and plastic behavior, meaning they deform slowly under stress and retain permanent deformation once the stress is removed. Understanding the viscoplastic response is crucial for designing components that withstand varying loads without failure in industries like automotive, aerospace, and manufacturing. Explore the rest of the article to discover how viscoplasticity impacts material performance and how you can apply this knowledge to your projects.

Table of Comparison

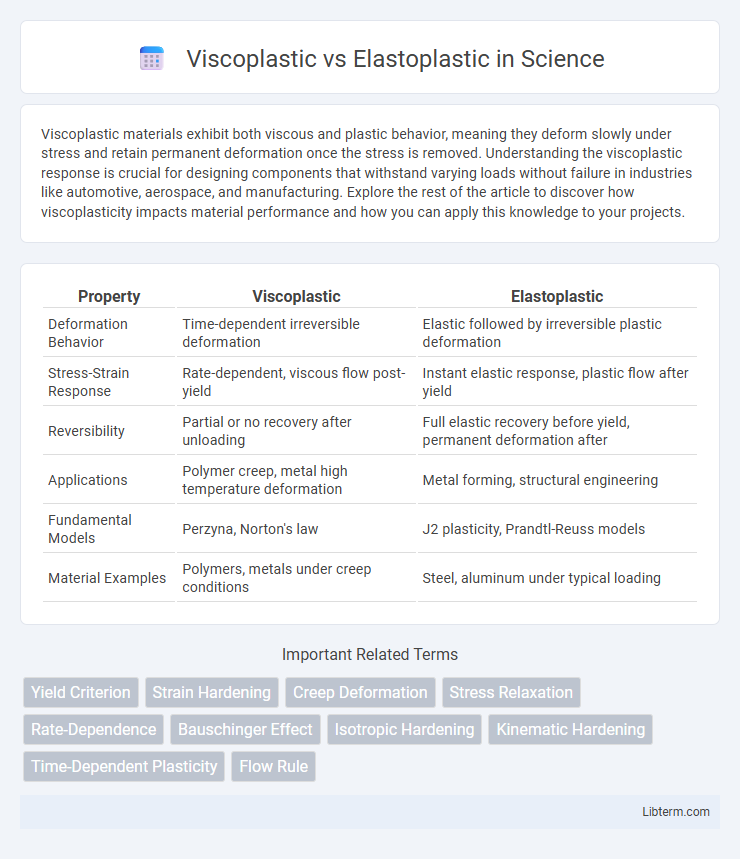

| Property | Viscoplastic | Elastoplastic |

|---|---|---|

| Deformation Behavior | Time-dependent irreversible deformation | Elastic followed by irreversible plastic deformation |

| Stress-Strain Response | Rate-dependent, viscous flow post-yield | Instant elastic response, plastic flow after yield |

| Reversibility | Partial or no recovery after unloading | Full elastic recovery before yield, permanent deformation after |

| Applications | Polymer creep, metal high temperature deformation | Metal forming, structural engineering |

| Fundamental Models | Perzyna, Norton's law | J2 plasticity, Prandtl-Reuss models |

| Material Examples | Polymers, metals under creep conditions | Steel, aluminum under typical loading |

Introduction to Viscoplastic and Elastoplastic Materials

Viscoplastic materials exhibit time-dependent plastic deformation under applied stress, combining viscous and plastic behavior that allows gradual strain accumulation even at constant loads. Elastoplastic materials demonstrate an initial elastic response followed by irreversible plastic deformation once the stress exceeds the yield point, with deformation occurring instantaneously without significant time dependency. Understanding the distinct deformation mechanisms and stress-strain responses of viscoplastic and elastoplastic materials is crucial for designing components subjected to complex loading conditions in fields such as structural engineering and materials science.

Fundamental Definitions: Viscoplasticity vs Elastoplasticity

Viscoplasticity describes materials that exhibit time-dependent irreversible deformation under stress, combining viscous flow with plastic deformation mechanisms. Elastoplasticity defines materials that deform elastically up to a yield point, beyond which plastic deformation occurs without any time-dependent effects. The fundamental distinction lies in viscoplastic models incorporating strain rate sensitivity and creep behavior, whereas elastoplastic models assume instantaneous plastic yielding after elastic limits are exceeded.

Key Differences in Material Behavior

Viscoplastic materials exhibit time-dependent plastic deformation under applied stress, characterized by a strain rate sensitivity, whereas elastoplastic materials combine elastic deformation with instantaneous plastic flow once yield stress is exceeded. Viscoplasticity involves gradual strain accumulation even under constant stress due to viscous effects, while elastoplastic behavior shows reversible elastic strain followed by irreversible plastic deformation without rate dependence. Stress-strain responses differ as viscoplastic materials display creep and stress relaxation phenomena, unlike elastoplastic materials that largely exhibit immediate elastic recovery post unloading.

Stress-Strain Characteristics Comparison

Viscoplastic materials exhibit time-dependent strain under constant stress, showing both viscous and plastic deformation behaviors, while elastoplastic materials combine elastic deformation with irreversible plastic strain without time dependence. Stress-strain curves for viscoplastic materials display rate-dependent yield points and gradual strain hardening, contrasting with elastoplastic curves that have a distinct yield point followed by strain hardening and unloading paths showing elastic recovery. The key difference lies in viscoplasticity's sensitivity to strain rate and permanent deformation under prolonged loading, whereas elastoplasticity emphasizes instantaneous elastic response followed by plastic flow.

Time-Dependent vs Time-Independent Responses

Viscoplastic materials exhibit time-dependent deformation where strain evolves continuously under constant stress, reflecting their rate-sensitive behavior characterized by viscosity and plasticity coupling. Elastoplastic materials respond in a time-independent manner, showing instantaneous elastic strain followed by permanent plastic deformation once stress exceeds the yield limit. The key distinction lies in viscoplasticity's dependence on strain rate and loading duration, whereas elastoplasticity's response is governed solely by stress levels without temporal effects.

Common Applications for Viscoplastic Materials

Viscoplastic materials, characterized by time-dependent irreversible deformation, are commonly used in applications such as metal forming, polymer processing, and geotechnical engineering where controlled flow under stress is essential. These materials are ideal for manufacturing components that require gradual shape changes, including automotive parts, packaging films, and construction materials like asphalt. Their ability to exhibit both viscous and plastic behavior under load makes them crucial in processes that demand energy dissipation and permanent deformation without fracture.

Common Applications for Elastoplastic Materials

Elastoplastic materials are widely used in structural engineering for their ability to undergo plastic deformation while retaining elastic properties, making them ideal for metal forming, automotive crash components, and earthquake-resistant building designs. These materials offer high durability and energy absorption, critical for load-bearing applications and safety equipment such as helmets and protective gear. Their common applications leverage both elasticity for shape recovery and plasticity for permanent shape change under stress, optimizing performance in mechanical and civil engineering fields.

Experimental Methods to Distinguish Behaviors

Experimental methods to distinguish viscoplastic from elastoplastic behaviors primarily involve stress relaxation tests and creep experiments, where viscoplastic materials exhibit time-dependent strain under constant stress, unlike elastoplastic materials which behave elastically until yield. Dynamic mechanical analysis (DMA) provides frequency-dependent modulus data, revealing viscoelastic or viscoplastic characteristics through phase lag between stress and strain. Micro-indentation testing combined with digital image correlation enhances spatial resolution of deformation, enabling differentiation based on rate-dependent irreversible strain accumulation in viscoplastic materials versus instant plastic deformation in elastoplastic ones.

Advantages and Limitations of Each Model

Viscoplastic models capture time-dependent plastic deformation, offering accurate predictions for materials under varying strain rates and improving simulation of creep and relaxation phenomena, but they require complex parameter calibration and higher computational costs. Elastoplastic models efficiently describe instantaneous plastic yielding and reversible elastic behavior, providing simplicity and reduced computational effort; however, they lack capability to model rate-dependent or time-dependent effects critical in viscoplastic behavior. Choosing between viscoplastic and elastoplastic frameworks depends on the need to balance fidelity in capturing strain-rate sensitivity and time-dependent effects against computational efficiency and model simplicity.

Summary Table: Viscoplastic vs Elastoplastic Properties

Viscoplastic materials exhibit time-dependent, irreversible deformation under stress, characterized by a continuous strain rate linked to viscous flow, while elastoplastic materials display immediate elastic deformation followed by permanent plastic deformation without time dependence. The summary table highlights key differences such as strain recovery--absent in viscoplasticity but partially present in elastoplasticity--and the presence of a yield stress in elastoplastic materials versus a rate-dependent yield condition for viscoplastic materials. Stress-strain behavior contrasts with viscoplasticity showing smooth, continuous curves and elastoplasticity demonstrating distinct elastic and plastic regions separated by a clear yield point.

Viscoplastic Infographic

libterm.com

libterm.com