Uniforms create a cohesive and professional appearance, enhancing brand identity and promoting equality among team members. They simplify daily wardrobe decisions while fostering a sense of belonging and discipline in various environments. Discover how choosing the right uniform can elevate your team's image and boost morale by reading the full article.

Table of Comparison

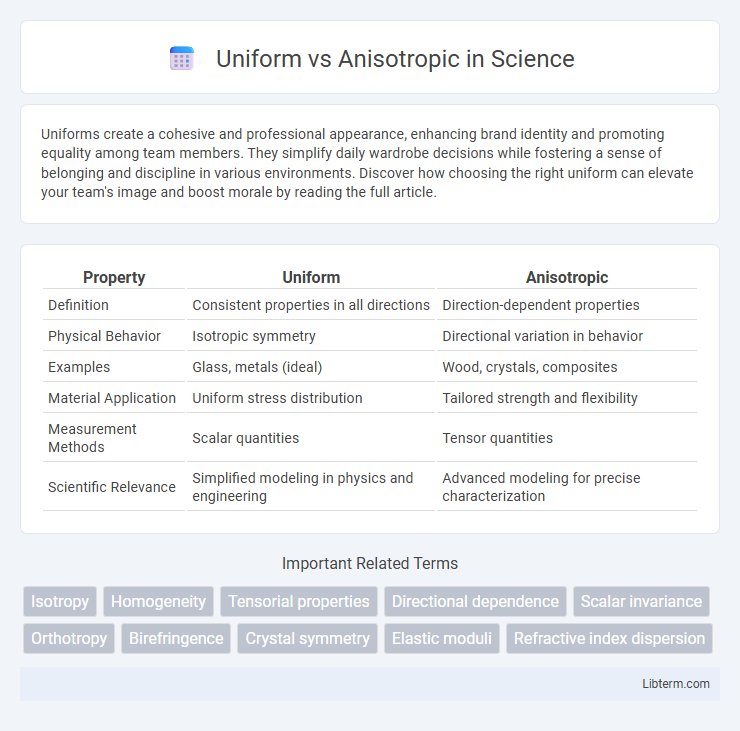

| Property | Uniform | Anisotropic |

|---|---|---|

| Definition | Consistent properties in all directions | Direction-dependent properties |

| Physical Behavior | Isotropic symmetry | Directional variation in behavior |

| Examples | Glass, metals (ideal) | Wood, crystals, composites |

| Material Application | Uniform stress distribution | Tailored strength and flexibility |

| Measurement Methods | Scalar quantities | Tensor quantities |

| Scientific Relevance | Simplified modeling in physics and engineering | Advanced modeling for precise characterization |

Introduction to Uniform and Anisotropic Materials

Uniform materials exhibit consistent properties throughout their structure, ensuring predictable behavior under various conditions. Anisotropic materials have directional dependence, meaning their physical or mechanical properties vary based on the orientation within the material. Understanding the distinction between uniform and anisotropic materials is crucial for applications in engineering, materials science, and manufacturing where performance under stress and environmental factors varies.

Defining Uniformity in Material Science

Uniformity in material science refers to the consistent distribution of physical and chemical properties throughout a material, ensuring isotropic behavior regardless of direction. Uniform materials exhibit identical mechanical, thermal, and electrical characteristics along all axes, contrasting with anisotropic materials whose properties vary based on orientation. Precise control of uniformity influences performance, durability, and reliability in applications ranging from composites to crystalline solids.

What is Anisotropy? Understanding Its Basics

Anisotropy refers to the directional dependence of a material's properties, meaning these properties vary when measured along different axes. Unlike uniform (isotropic) materials that exhibit identical characteristics in all directions, anisotropic materials display variation in parameters such as mechanical strength, thermal conductivity, or optical behavior depending on orientation. Key examples include crystals, composite materials, and biological tissues where anisotropy significantly impacts performance and functionality.

Key Differences: Uniform vs Anisotropic Properties

Uniform properties exhibit consistent characteristics in all directions, ensuring homogeneity and predictable behavior across a material or system. Anisotropic properties vary depending on the direction, leading to differences in strength, conductivity, or refractive index based on orientation. This directional dependence in anisotropy is critical for applications requiring tailored mechanical or optical performance.

Mechanical Behavior: Uniformity vs Anisotropy

Uniform mechanical behavior refers to materials exhibiting consistent properties such as strength, stiffness, and ductility in all directions, often seen in isotropic metals and polymers. Anisotropic materials demonstrate direction-dependent mechanical properties due to their internal structure, like composites or wood, where strength and elasticity vary along different axes. Understanding this distinction is crucial for engineering applications requiring predictable performance under multi-directional stresses.

Real-world Examples of Uniform and Anisotropic Materials

Uniform materials like glass and pure metals exhibit isotropic properties, meaning their mechanical, optical, and thermal characteristics remain consistent regardless of direction. Anisotropic materials, such as wood, carbon fiber composites, and certain crystals like calcite, display varying strength, conductivity, or refractive indices depending on their orientation. These differences influence applications in industries ranging from construction and aerospace to electronics and optics, where directional properties are critical for performance and durability.

Applications Demanding Uniformity

Applications demanding uniformity require materials or processes with consistent properties throughout, ensuring predictable performance in critical fields such as optical coatings, electronics, and precision manufacturing. Uniform materials minimize variability in mechanical, thermal, and electrical characteristics, essential for producing high-quality semiconductor wafers, display panels, and biomedical devices. Achieving uniformity reduces defects, enhances reliability, and optimizes efficiency in mass production environments where precision and consistency are paramount.

Industries Benefiting from Anisotropic Materials

Anisotropic materials exhibit direction-dependent properties, providing tailored mechanical, thermal, or electrical characteristics essential in aerospace, automotive, and electronics industries, where precise performance and strength variability enhance product reliability. These materials improve composite structures, enabling lightweight designs with superior stress resistance, crucial for high-performance aircraft and electric vehicle components. Advanced manufacturing sectors leverage anisotropic materials to optimize heat dissipation and electrical conductivity in semiconductors and flexible displays.

Challenges in Measuring Uniform and Anisotropic Characteristics

Measuring uniform and anisotropic characteristics presents significant challenges due to variations in material properties across different directions, complicating accurate data collection and analysis. Uniform materials require consistent measurement techniques to ensure homogeneity, while anisotropic materials demand advanced instrumentation capable of capturing directional dependencies with high precision. Calibration issues, sensor alignment, and environmental factors further complicate the reliability and reproducibility of measurements in both uniform and anisotropic contexts.

Future Trends: From Uniform to Anisotropic Engineering

Future trends in material science highlight a shift from uniform to anisotropic engineering, enabling precise control over directional properties such as thermal conductivity, electrical resistance, and mechanical strength. Advances in additive manufacturing and nanotechnology facilitate the design of customized anisotropic structures tailored for applications in aerospace, electronics, and biomedical devices. This transition promises enhanced performance and functionality by leveraging the inherent directional dependencies within engineered materials.

Uniform Infographic

libterm.com

libterm.com