Composite materials combine two or more distinct substances to create a product with enhanced properties such as increased strength, durability, and reduced weight. Widely used in aerospace, automotive, and construction industries, composites offer superior resistance to environmental factors and stress. Explore the full article to discover how composites can improve your projects through innovative applications and benefits.

Table of Comparison

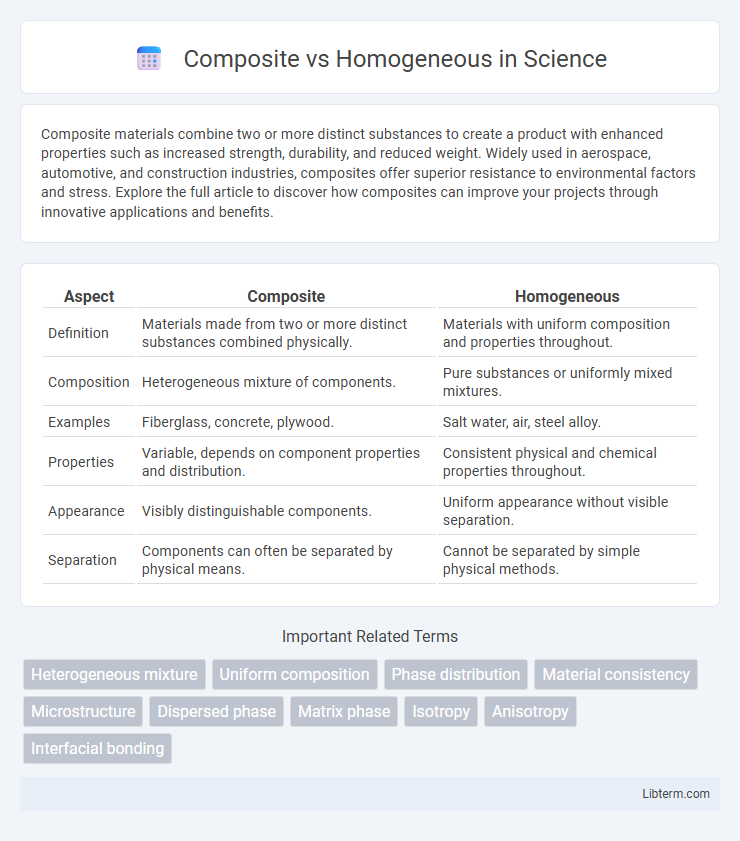

| Aspect | Composite | Homogeneous |

|---|---|---|

| Definition | Materials made from two or more distinct substances combined physically. | Materials with uniform composition and properties throughout. |

| Composition | Heterogeneous mixture of components. | Pure substances or uniformly mixed mixtures. |

| Examples | Fiberglass, concrete, plywood. | Salt water, air, steel alloy. |

| Properties | Variable, depends on component properties and distribution. | Consistent physical and chemical properties throughout. |

| Appearance | Visibly distinguishable components. | Uniform appearance without visible separation. |

| Separation | Components can often be separated by physical means. | Cannot be separated by simple physical methods. |

Understanding Composite and Homogeneous Materials

Composite materials consist of two or more distinct phases combined at a macroscopic level, providing enhanced mechanical, thermal, or chemical properties that individual components cannot achieve alone. Homogeneous materials have uniform composition and structure throughout, resulting in consistent material properties in every part. Understanding the microstructural differences between composite and homogeneous materials is essential for selecting appropriate applications in aerospace, automotive, and construction industries.

Key Differences Between Composite and Homogeneous Structures

Composite structures combine multiple materials with distinct physical or chemical properties to achieve enhanced mechanical performance, while homogeneous structures consist of a single material with uniform composition throughout. The key differences include anisotropy in composites, where properties vary with direction, compared to the isotropy of homogeneous materials that exhibit consistent properties in all directions. Composites provide tailored strength, stiffness, and weight advantages ideal for aerospace and automotive applications, whereas homogeneous materials offer simplicity in manufacturing and predictable behavior under stress.

Advantages of Composite Materials

Composite materials offer superior strength-to-weight ratios compared to homogeneous materials, making them ideal for aerospace and automotive applications where weight reduction is critical. Their enhanced corrosion resistance and fatigue durability extend the lifespan of structures, reducing maintenance costs and improving safety. Customizable properties such as stiffness, thermal conductivity, and impact resistance provide engineers with versatile options for optimizing performance in specialized environments.

Benefits of Homogeneous Materials

Homogeneous materials offer consistent mechanical and thermal properties throughout their structure, ensuring predictable performance and durability in engineering applications. Their uniform composition simplifies manufacturing processes and enhances material reliability by reducing the risk of weak points or defects. This uniformity is particularly beneficial in precision industries where consistent material behavior under stress is critical.

Common Applications of Composite Materials

Composite materials, combining two or more distinct substances, are widely used in aerospace, automotive, and construction industries for their superior strength-to-weight ratios and corrosion resistance. Common applications include carbon fiber-reinforced polymers in aircraft structures, fiberglass in boat hulls, and concrete with steel reinforcement in building foundations. Homogeneous materials, in contrast, are typically utilized where uniform properties are required, such as metals and plastics for everyday manufacturing.

Typical Uses of Homogeneous Materials

Homogeneous materials are commonly used in applications requiring uniform properties throughout the material, such as metals in structural engineering, glass in windows, and polymers in packaging. Their consistent composition ensures predictable mechanical, thermal, and chemical behavior, making them ideal for precision instruments, piping, and consumer electronics. Typical uses include aerospace components, automotive parts, and medical devices where reliability and uniformity are critical.

Strength and Durability Comparison

Composite materials typically exhibit superior strength-to-weight ratios and enhanced durability compared to homogeneous materials due to their mixed constituent phases, such as fiber-reinforced polymers incorporating carbon or glass fibers. Homogeneous materials, like metals or pure polymers, often provide uniform properties but lack the tailored mechanical reinforcement found in composites, resulting in lower resistance to fatigue, impact, and environmental degradation. Advanced composites maintain structural integrity under stress and harsh conditions, making them ideal for aerospace, automotive, and construction applications where high strength and longevity are critical.

Cost Considerations: Composite vs Homogeneous

Composite materials generally offer lower lifecycle costs compared to homogeneous materials due to their enhanced strength-to-weight ratios and durability, which reduce maintenance and replacement expenses. Homogeneous materials often have higher initial costs and may require more frequent repairs or replacements, increasing long-term expenditures. Choosing composites can optimize cost efficiency in applications demanding performance and longevity.

Environmental Impact and Sustainability

Composite materials often have a higher environmental impact due to challenges in recycling and resource-intensive production processes, whereas homogeneous materials tend to be more sustainable because they are easier to recycle and reuse. The durability and longevity of composites can reduce the need for frequent replacements, partially offsetting their initial environmental footprint. Sustainable design increasingly favors recyclable homogeneous materials to minimize waste and promote circular economy goals.

Choosing the Right Material for Your Project

Composite materials combine two or more distinct substances, offering enhanced strength, durability, and lightweight properties suitable for complex engineering projects. Homogeneous materials consist of a single, uniform composition, providing consistent mechanical and thermal properties ideal for applications requiring predictability and ease of machining. Selecting the right material depends on project requirements such as load-bearing capacity, environmental resistance, and cost-effectiveness, with composites excelling in high-performance scenarios and homogeneous materials preferred for straightforward, uniform tasks.

Composite Infographic

libterm.com

libterm.com