Anisotropic materials exhibit different properties depending on the direction of measurement, influencing factors such as strength, conductivity, and refractive index. Understanding anisotropy is crucial for applications in engineering, materials science, and optics, where direction-dependent behavior affects performance and design. Discover how anisotropic characteristics impact various industries and why your knowledge of this concept matters by reading the full article.

Table of Comparison

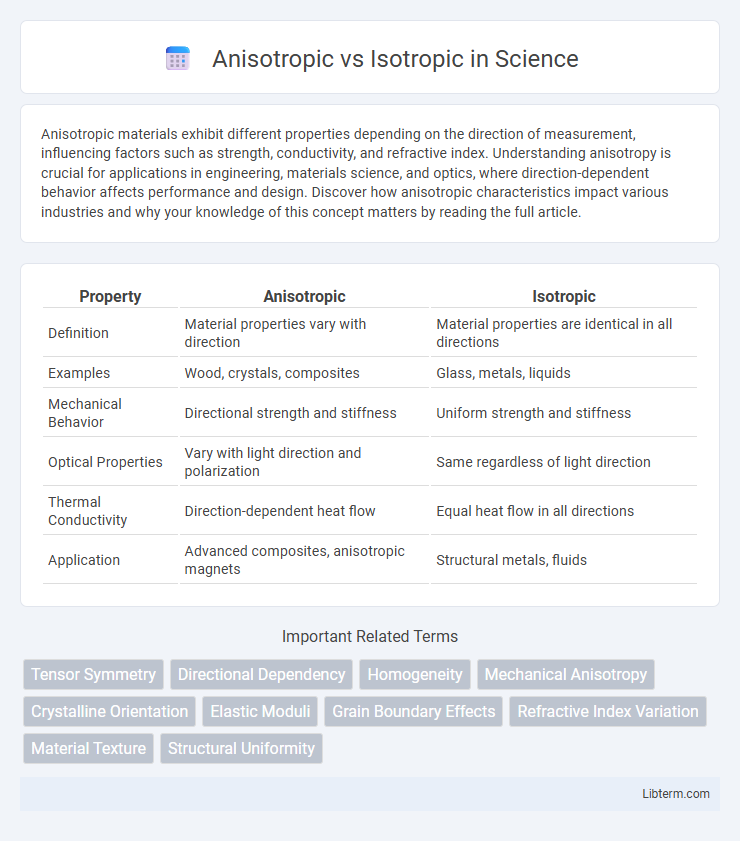

| Property | Anisotropic | Isotropic |

|---|---|---|

| Definition | Material properties vary with direction | Material properties are identical in all directions |

| Examples | Wood, crystals, composites | Glass, metals, liquids |

| Mechanical Behavior | Directional strength and stiffness | Uniform strength and stiffness |

| Optical Properties | Vary with light direction and polarization | Same regardless of light direction |

| Thermal Conductivity | Direction-dependent heat flow | Equal heat flow in all directions |

| Application | Advanced composites, anisotropic magnets | Structural metals, fluids |

Understanding Anisotropy and Isotropy

Anisotropy describes materials or properties that vary based on direction, affecting physical characteristics like thermal conductivity, refractive index, and mechanical strength. Isotropy refers to uniformity in properties regardless of direction, ensuring consistent behavior in materials such as isotropic metals or glass. Understanding anisotropy and isotropy is critical in fields like materials science, optics, and engineering for tailoring applications that depend on directional dependencies or uniformity.

Key Differences Between Anisotropic and Isotropic Materials

Anisotropic materials exhibit direction-dependent properties, meaning their mechanical, thermal, or electrical characteristics vary based on the orientation of measurement, unlike isotropic materials which have uniform properties in all directions. Anisotropic materials include composites and certain crystals, offering tailored performance, whereas isotropic materials such as metals and glasses provide consistent behavior regardless of directional forces. The key difference lies in the variability of responses under stress or strain, which significantly impacts design decisions in engineering, materials science, and manufacturing processes.

Physical Properties: Anisotropic vs Isotropic

Anisotropic materials exhibit direction-dependent physical properties such as thermal conductivity, electrical resistivity, and mechanical strength, varying significantly along different crystallographic axes. Isotropic materials possess uniform physical properties in all directions, resulting in consistent behavior regardless of orientation. Understanding these differences is crucial for applications in materials science, engineering, and nanotechnology where directional properties impact performance and functionality.

Common Examples in Nature and Technology

Anisotropic materials, such as wood, crystals, and liquid crystals, exhibit direction-dependent properties, making them essential in technologies like LCD screens and fiber optics. Isotropic materials, including metals like copper, glass, and water, have uniform properties in all directions, which is crucial for applications requiring consistent strength and thermal conductivity. Understanding the distinction between anisotropic and isotropic behaviors informs the design of advanced composites, sensors, and structural components in various engineering fields.

Applications of Anisotropic Materials

Anisotropic materials exhibit directional dependence in their physical properties, making them essential in advanced applications like aerospace composites, where strength and stiffness vary with orientation for optimized performance. In electronics, anisotropic conductive films enable precise electrical connectivity by conducting current in one direction while insulating in others. Their use in medical imaging, such as MRI contrast agents, leverages anisotropic magnetic susceptibility to enhance image resolution and contrast.

Advantages and Limitations of Isotropic Materials

Isotropic materials exhibit uniform properties in all directions, offering consistent mechanical strength, thermal conductivity, and electrical performance, which simplifies design and analysis in engineering applications. Their advantages include predictable behavior under stress and ease of manufacturing due to homogeneous structure. However, isotropic materials may lack the enhanced directional properties found in anisotropic materials, limiting their effectiveness in applications requiring tailored strength or conductivity along specific axes.

Measurement Techniques for Anisotropy and Isotropy

Measurement techniques for anisotropy often involve directional analysis methods such as X-ray diffraction (XRD) and polarized light microscopy, which assess variations in physical properties along different axes. Isotropy measurement typically employs uniform property evaluations through techniques like ultrasonic testing or thermal conductivity tests, ensuring consistency in all directions. Advanced methods such as electron backscatter diffraction (EBSD) provide detailed microstructural information critical for distinguishing anisotropic from isotropic materials.

Anisotropy and Isotropy in Engineering Design

Anisotropy in engineering design refers to materials or structures exhibiting direction-dependent properties, such as varying strength, stiffness, or thermal conductivity along different axes, which is critical for optimizing performance in applications like composite materials and aerospace components. Isotropy describes materials with uniform properties in all directions, simplifying analysis and manufacturing processes but potentially limiting design flexibility in performance-critical environments. Engineers select anisotropic or isotropic materials based on application demands, balancing factors like load distribution, durability, and weight considerations.

Impact on Performance and Durability

Anisotropic materials exhibit direction-dependent properties that enhance performance by optimizing strength and stiffness along specific orientations, leading to improved durability in applications like composite structures and aerospace components. Isotropic materials, with uniform properties in all directions, offer consistent but generally lower performance, which can limit their durability under directional stress or strain. Understanding these differences allows engineers to select materials that maximize longevity and efficiency based on specific load conditions and environmental factors.

Choosing Between Anisotropic and Isotropic Materials

Choosing between anisotropic and isotropic materials depends on the specific mechanical and thermal performance requirements of the application. Anisotropic materials, such as composites and single crystals, offer directional strength and stiffness, making them ideal for aerospace, automotive, and structural components that demand tailored properties. Isotropic materials, including metals like aluminum and steel, provide uniform properties in all directions, simplifying design and manufacturing processes for general-purpose applications.

Anisotropic Infographic

libterm.com

libterm.com