Transitional periods in life often bring significant changes that require adaptability and resilience. These phases can impact your personal growth, relationships, and career trajectory in profound ways. Explore the rest of this article to discover strategies for navigating transitions successfully.

Table of Comparison

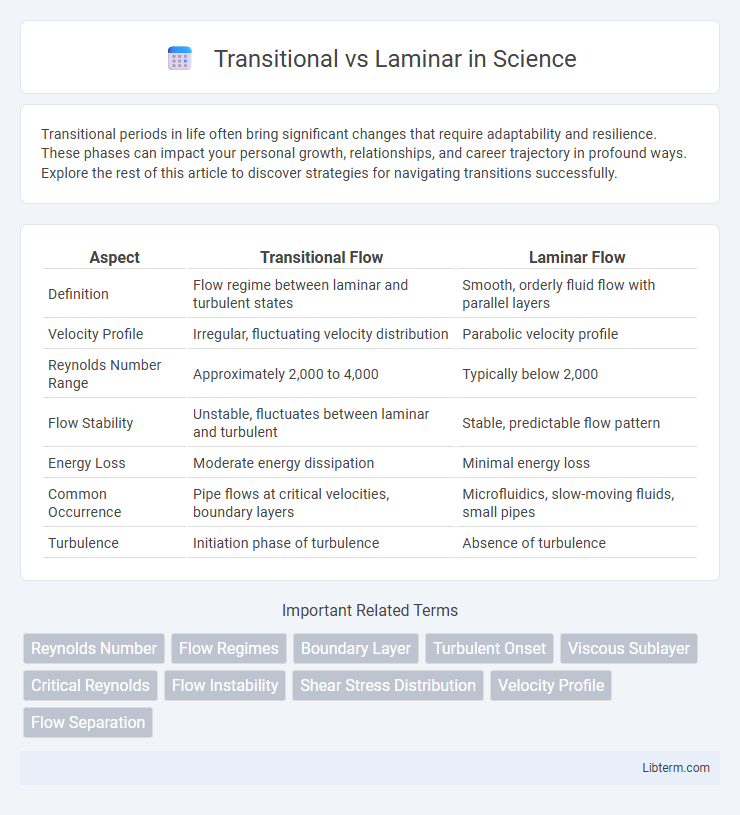

| Aspect | Transitional Flow | Laminar Flow |

|---|---|---|

| Definition | Flow regime between laminar and turbulent states | Smooth, orderly fluid flow with parallel layers |

| Velocity Profile | Irregular, fluctuating velocity distribution | Parabolic velocity profile |

| Reynolds Number Range | Approximately 2,000 to 4,000 | Typically below 2,000 |

| Flow Stability | Unstable, fluctuates between laminar and turbulent | Stable, predictable flow pattern |

| Energy Loss | Moderate energy dissipation | Minimal energy loss |

| Common Occurrence | Pipe flows at critical velocities, boundary layers | Microfluidics, slow-moving fluids, small pipes |

| Turbulence | Initiation phase of turbulence | Absence of turbulence |

Understanding Flow Dynamics: Transitional vs. Laminar

Transitional flow occurs when fluid velocity or other factors push the flow state between smooth laminar patterns and chaotic turbulent behavior, typically characterized by fluctuating velocity fields and increasing instability. Laminar flow exhibits orderly, layered fluid motion with minimal mixing, where velocity profiles are stable and predictable, often described by low Reynolds numbers below approximately 2,000. Understanding the distinction influences applications in aerodynamics and pipeline design by predicting pressure drops, drag, and heat transfer efficiency based on flow regime behavior.

Defining Laminar Flow: Key Characteristics

Laminar flow is characterized by smooth, orderly fluid motion with parallel layers that do not mix, resulting in minimal turbulence and friction. This flow regime typically occurs at low Reynolds numbers, usually below 2,000, where viscous forces dominate inertial forces. The predictability and low energy loss of laminar flow are critical for applications in aerodynamics, fluid mechanics, and medical devices.

What Is Transitional Flow? Core Features

Transitional flow occurs between laminar and turbulent flow, where fluid motion exhibits both smooth and chaotic characteristics. Core features include fluctuating velocity patterns, intermittent bursts of turbulence, and variable Reynolds numbers typically ranging from 2,000 to 4,000 in pipe flow. This flow regime is critical in engineering applications because it affects heat transfer, drag, and mixing rates.

Key Differences Between Transitional and Laminar Flow

Transitional flow occurs between laminar and turbulent flow, characterized by fluctuating velocity and intermittent bursts of turbulence, whereas laminar flow features smooth, orderly layers with minimal mixing. Key differences include Reynolds number ranges, with laminar flow typically below 2300 and transitional flow between 2300 and 4000, and the stability of the flow pattern, where laminar flow is stable and transitional flow is unstable. The impact on pressure drop and heat transfer efficiency also differs, as laminar flow exhibits lower pressure loss but reduced mixing compared to the enhanced mixing in transitional flow.

Factors Influencing the Transition of Flow

Flow transition from laminar to turbulent is influenced by factors such as Reynolds number, surface roughness, and flow velocity. Higher Reynolds numbers increase instability, prompting flow disturbances that grow and cause transition. Surface irregularities and velocity gradients amplify perturbations, accelerating the onset of turbulent flow in boundary layers.

Importance of Reynolds Number in Flow Analysis

Reynolds number serves as a critical parameter in distinguishing between laminar and transitional flow regimes by quantifying the ratio of inertial forces to viscous forces within a fluid. When Reynolds number remains below approximately 2,300, flow maintains a smooth, laminar state characterized by orderly fluid motion; beyond this threshold, flow transitions into a more chaotic and unstable transitional phase. Understanding the Reynolds number enables engineers and scientists to predict flow behavior, optimize fluid dynamics in applications such as pipe transport, aerodynamic design, and heat exchangers, thereby improving performance and efficiency.

Applications of Laminar Flow in Industry

Laminar flow, characterized by smooth, orderly fluid motion with minimal mixing, is crucial in industries requiring precise control over fluid dynamics, such as semiconductor manufacturing, pharmaceutical production, and cleanroom environments. This flow regime ensures contaminant-free conditions by minimizing turbulence and particle suspension, enhancing product quality and process reliability. In contrast, transitional flow, which exhibits fluctuating and unstable fluid behavior, is less desirable in applications demanding stringent environmental control.

Real-World Examples of Transitional Flow

Transitional flow occurs in scenarios such as blood flow in arteries, where velocity and pressure variations cause shifts between laminar and turbulent states, affecting cardiovascular health. In environmental studies, transitional flow is observed in river bends and estuaries, where changing water speed and obstacles create complex mixing patterns crucial for sediment transport and aquatic ecosystems. These examples highlight how transitional flow impacts engineering designs and natural processes requiring precise flow management.

Impact on Fluid Mechanics and Engineering Design

Transitional flow exhibits characteristics between laminar and turbulent regimes, causing fluctuations that impact fluid momentum and heat transfer rates differently than laminar flow, which is smooth and orderly. Engineers must account for the increased drag and potential flow separation in transitional flows when designing aerodynamic surfaces, pipelines, and heat exchangers to ensure efficiency and structural integrity. Accurate prediction of transitional behavior using criteria such as Reynolds number is critical for optimizing performance and avoiding premature failure in fluid systems.

Future Trends in Transitional and Laminar Flow Research

Future trends in transitional and laminar flow research emphasize advanced computational modeling techniques and machine learning algorithms to predict flow behavior with higher accuracy. Innovations in experimental methods, such as microfluidics and high-resolution flow visualization, aim to capture complex transitional phenomena at smaller scales. These advancements contribute to optimizing aerodynamic designs and energy-efficient systems across aerospace, automotive, and biomedical engineering applications.

Transitional Infographic

libterm.com

libterm.com