A reboiler plays a crucial role in distillation processes by providing the necessary heat to vaporize the liquid mixture, ensuring efficient separation. Heat exchangers transfer thermal energy between fluids, optimizing temperature control and energy use within industrial systems. Explore the article to understand how reboilers and heat exchangers enhance your operational efficiency.

Table of Comparison

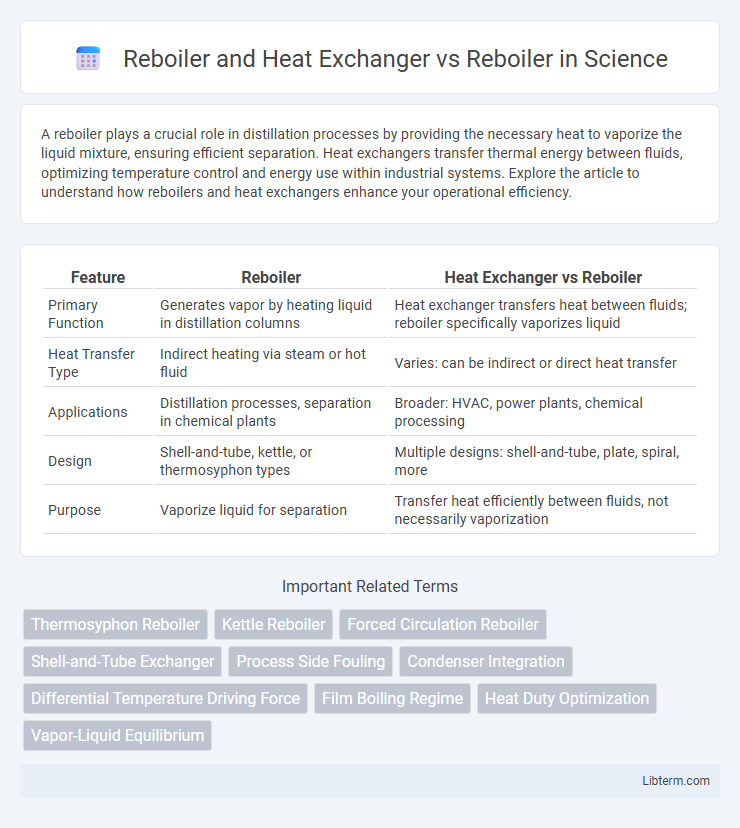

| Feature | Reboiler | Heat Exchanger vs Reboiler |

|---|---|---|

| Primary Function | Generates vapor by heating liquid in distillation columns | Heat exchanger transfers heat between fluids; reboiler specifically vaporizes liquid |

| Heat Transfer Type | Indirect heating via steam or hot fluid | Varies: can be indirect or direct heat transfer |

| Applications | Distillation processes, separation in chemical plants | Broader: HVAC, power plants, chemical processing |

| Design | Shell-and-tube, kettle, or thermosyphon types | Multiple designs: shell-and-tube, plate, spiral, more |

| Purpose | Vaporize liquid for separation | Transfer heat efficiently between fluids, not necessarily vaporization |

Introduction to Reboilers and Heat Exchangers

Reboilers are specialized heat exchangers designed to supply the necessary heat to distillation columns by vaporizing the bottom liquid mixture. Heat exchangers, including reboilers, transfer thermal energy between two fluids without direct contact, optimizing energy consumption and process efficiency. Understanding the role of reboilers as integral heat exchangers highlights their critical function in maintaining temperature gradients essential for effective separation processes.

What Is a Reboiler?

A reboiler is a heat exchanger specifically designed to provide the necessary heat to the bottom of a distillation column, vaporizing the liquid mixture to facilitate separation. Unlike general heat exchangers, reboilers operate at high temperatures and pressures to generate vapor directly within the process system. Their critical function in continuous distillation processes ensures efficient energy transfer and effective phase separation.

Types of Reboilers in Industry

Industrial reboilers are critical components used to supply heat to distillation columns, with common types including kettle, thermosiphon, forced circulation, and bayonet reboilers. Each reboiler type offers distinct advantages: kettle reboilers provide stable liquid levels and efficient heat transfer, thermosiphon reboilers rely on natural circulation for energy savings, while forced circulation reboilers handle high-viscosity fluids and fouling. Unlike general heat exchangers, reboilers are specifically designed for vapor generation, emphasizing boiling efficiency and phase change optimization essential in chemical, petrochemical, and refining industries.

Fundamentals of Heat Exchangers

Reboilers and heat exchangers both facilitate heat transfer to process fluids, but reboilers specifically provide the latent heat necessary to vaporize liquid in distillation columns by boiling a portion of the bottom product. Heat exchangers encompass a broader category that transfers heat between two or more fluids without phase change, emphasizing sensible heat transfer based on conduction and convection principles. Understanding the fundamentals of heat exchangers, including the types like shell-and-tube and plate designs, heat transfer coefficients, and fouling effects, is crucial for optimizing reboiler performance and ensuring energy-efficient operation.

Key Differences: Reboiler vs Heat Exchanger

Reboilers and heat exchangers both transfer heat, but reboilers specifically generate vapor to drive distillation by boiling the liquid in a distillation column, whereas heat exchangers transfer heat between two fluids without phase change. Reboilers often operate at higher temperatures to vaporize the liquid, while heat exchangers maintain fluid temperatures without boiling. The primary function of reboilers is vapor production, contrasting with heat exchangers that focus on efficient thermal energy exchange.

Applications of Reboilers in Process Industries

Reboilers play a critical role in process industries by providing the necessary heat to facilitate vapor-liquid separation in distillation columns, a function distinct from general heat exchangers which transfer heat without phase change emphasis. Common applications of reboilers include refining crude oil in petroleum plants, concentrating chemical solutions in the chemical industry, and recovering solvents in pharmaceutical manufacturing. The efficiency of reboilers directly impacts product purity, energy consumption, and overall process optimization in these sectors.

Design Considerations for Reboilers

Reboilers require careful design considerations including thermal duty, fluid properties, pressure drop, and compatibility with process fluids to ensure efficient phase separation and heat transfer. Unlike general heat exchangers, reboiler designs must prevent fouling, accommodate vapor disengagement, and maintain safe operating temperatures to avoid degradation of process fluids. Material selection and maintenance accessibility are critical for extending reboiler lifecycle and optimizing energy efficiency within distillation columns or evaporators.

Efficiency Comparison: Reboiler and Heat Exchanger

Reboilers combined with heat exchangers offer enhanced thermal efficiency by maximizing heat recovery from process streams and minimizing energy loss, often achieving up to 95% energy utilization compared to standalone reboilers that typically operate around 70-80%. The integration of heat exchangers optimizes the heat transfer process, reducing fuel consumption and operational costs significantly in distillation setups. This synergy improves process stability and throughput by maintaining consistent temperature profiles, making the combined system superior in energy efficiency and performance.

Operational Challenges and Maintenance

Reboilers and heat exchangers face operational challenges such as fouling, corrosion, and thermal stresses that reduce efficiency and increase downtime. Reboilers require frequent monitoring of tube integrity and scale buildup to maintain optimal heat transfer rates, while combined heat exchanger-reboiler units demand complex maintenance strategies to address both heat exchange surfaces and vaporization zones. Effective preventive maintenance includes routine cleaning, inspection, and material upgrades to minimize unplanned outages and extend equipment lifespan.

Choosing the Right Equipment: Factors to Consider

Selecting the right equipment between a combined reboiler and heat exchanger versus a standalone reboiler depends on factors such as heat transfer efficiency, process temperature, and space constraints. Integrated units offer compact design and energy savings by utilizing heat from the process fluid, while standalone reboilers provide greater operational flexibility and easier maintenance. Material compatibility, pressure ratings, and fouling tendencies must also be evaluated to optimize performance and lifespan in specific industrial applications.

Reboiler and Heat Exchanger Infographic

libterm.com

libterm.com