Elastic materials exhibit the ability to return to their original shape after being stretched or compressed, making them essential in various applications from clothing to industrial products. Understanding the properties of elasticity can help you choose the right materials for durability and flexibility. Explore the rest of the article to learn how elasticity impacts everyday items and innovative technologies.

Table of Comparison

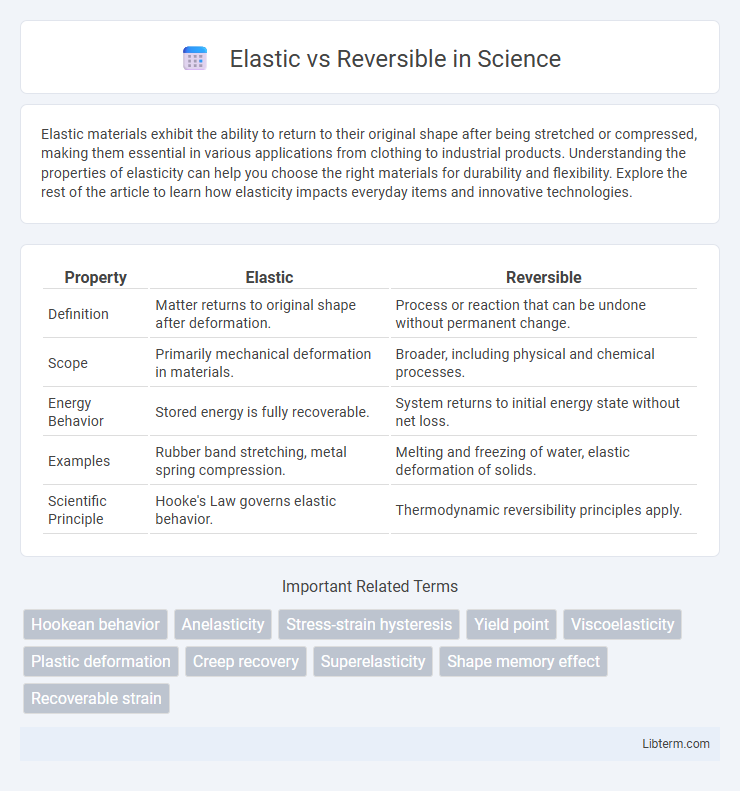

| Property | Elastic | Reversible |

|---|---|---|

| Definition | Matter returns to original shape after deformation. | Process or reaction that can be undone without permanent change. |

| Scope | Primarily mechanical deformation in materials. | Broader, including physical and chemical processes. |

| Energy Behavior | Stored energy is fully recoverable. | System returns to initial energy state without net loss. |

| Examples | Rubber band stretching, metal spring compression. | Melting and freezing of water, elastic deformation of solids. |

| Scientific Principle | Hooke's Law governs elastic behavior. | Thermodynamic reversibility principles apply. |

Introduction to Elastic and Reversible Processes

Elastic processes involve deformation of materials that return to their original shape upon the removal of applied stress, adhering to Hooke's Law within the elastic limit. Reversible processes refer to thermodynamic changes that can be reversed without increasing entropy or dissipating energy, maintaining equilibrium throughout the transformation. Understanding the distinction between elastic mechanical behavior and reversible thermodynamic processes is essential for applications in materials science and thermodynamics.

Defining Elastic Changes

Elastic changes refer to temporary deformations where a material returns to its original shape after the removal of stress, characterized by reversible molecular rearrangements within elastic limits. These changes occur when stress remains below the yield strength, ensuring no permanent distortion or damage to the material's structure. Elastic deformation is fundamental in materials science for applications requiring resilience and energy absorption without permanent alteration.

Understanding Reversible Processes

Reversible processes in thermodynamics maintain equilibrium at every stage, allowing the system to return to its initial state without entropy change. Unlike elastic deformations that instantaneously recover shape upon stress removal, reversible processes involve infinitesimal changes ensuring no energy dissipation or hysteresis. Mastery of reversible processes enables accurate determination of maximum work output and efficient energy transformations in heat engines and thermodynamic cycles.

Key Differences: Elastic vs Reversible

Elastic deformation involves temporary shape change where materials return to their original form after the applied stress is removed, highlighting its non-permanent nature. Reversible deformation encompasses broader physical or chemical processes where changes can be undone, including phase transitions or molecular rearrangements that restore the initial state. Key differences lie in elasticity being a subset of reversible behavior primarily concerned with mechanical stress-strain relationships, while reversible processes extend beyond mechanical changes to include thermodynamic and chemical reversibility.

Examples of Elastic Materials

Rubber bands, natural rubber, and silicone are common examples of elastic materials known for their ability to return to their original shape after deformation. Metals such as steel and aluminum exhibit elastic properties within their elastic limit, allowing temporary shape changes under stress. Elastic materials differ from reversible systems in that their deformation is primarily physical and recoverable without permanent change.

Real-Life Instances of Reversible Changes

Reversible changes occur in everyday scenarios such as melting ice, where water repeatedly freezes and thaws without altering its chemical structure. Stretching a rubber band exemplifies elasticity, as it returns to its original shape once the force is removed. Boiling water and condensation also demonstrate reversible physical transformations, maintaining molecular integrity throughout the process.

Application in Physics and Engineering

Elastic materials store mechanical energy and return to their original shape after deformation, making them essential in structural engineering for designing resilient bridges and buildings. Reversible processes in physics describe ideal transformations where systems return to their initial state without energy loss, critical for thermodynamic cycle analysis in engines and refrigerators. Both concepts underpin efficient energy management and mechanical stability in engineering applications.

Importance in Material Science

Elastic and reversible deformations are critical concepts in material science, influencing the durability and performance of materials under stress. Elastic deformation refers to temporary shape changes that disappear upon load removal, ensuring materials resume original dimensions, which is essential for structural applications requiring resilience. Reversible deformation emphasizes the material's ability to undergo and recover from strain without permanent alteration, crucial for designing flexible electronics, sensors, and adaptive materials that maintain functionality through repeated cycles.

Factors Affecting Elasticity and Reversibility

Elasticity depends on factors such as temperature, material composition, and strain rate, which influence how a material deforms and returns to its original shape. Reversibility is affected by the molecular structure and the extent of stress applied, determining whether the deformation is temporary or leads to permanent changes. Materials with strong intermolecular bonds and low plastic deformation exhibit higher elasticity and greater reversibility under stress.

Conclusion: Choosing the Right Process

Choosing between elastic and reversible processes depends on the desired outcome and material properties. Elastic processes allow temporary shape change without permanent deformation, ideal for applications needing flexibility and resilience. Reversible processes enable full restoration after alteration, critical in systems requiring repeatable functionality and minimal wear.

Elastic Infographic

libterm.com

libterm.com