Plastic plays a crucial role in everyday life due to its versatility, durability, and cost-effectiveness, making it indispensable in packaging, construction, and medical devices. Understanding the environmental impact of plastic waste and exploring innovative recycling methods can help mitigate pollution and promote sustainability. Discover how you can contribute to reducing plastic waste by reading the rest of this article.

Table of Comparison

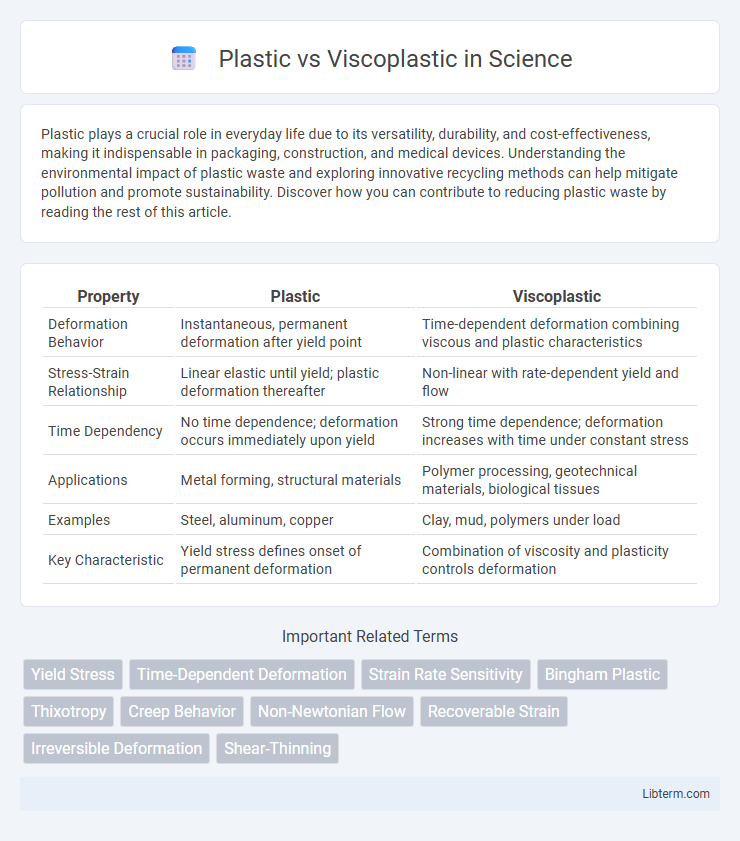

| Property | Plastic | Viscoplastic |

|---|---|---|

| Deformation Behavior | Instantaneous, permanent deformation after yield point | Time-dependent deformation combining viscous and plastic characteristics |

| Stress-Strain Relationship | Linear elastic until yield; plastic deformation thereafter | Non-linear with rate-dependent yield and flow |

| Time Dependency | No time dependence; deformation occurs immediately upon yield | Strong time dependence; deformation increases with time under constant stress |

| Applications | Metal forming, structural materials | Polymer processing, geotechnical materials, biological tissues |

| Examples | Steel, aluminum, copper | Clay, mud, polymers under load |

| Key Characteristic | Yield stress defines onset of permanent deformation | Combination of viscosity and plasticity controls deformation |

Introduction to Plastic and Viscoplastic Materials

Plastic materials exhibit a permanent deformation when subjected to stress beyond their yield point, characterized by a linear elastic region followed by plastic flow without time-dependent effects. Viscoplastic materials combine viscous and plastic behavior, showing rate-dependent deformation where strain accumulates over time under constant stress, commonly described by models such as Perzyna or Bingham. Understanding the differences between plastic and viscoplastic responses is crucial for applications in metal forming, polymer processing, and geotechnical engineering.

Fundamental Definitions: Plasticity and Viscoplasticity

Plasticity defines a material's ability to undergo irreversible deformation without returning to its original shape when the applied stress is removed. Viscoplasticity combines viscosity and plasticity, describing materials that exhibit time-dependent, rate-sensitive irreversible deformation under stress. Understanding these fundamental definitions is crucial for analyzing material behavior in engineering applications involving metals, polymers, and soils.

Key Differences in Material Behavior

Plastic materials exhibit a permanent deformation after the yield point is reached, maintaining a constant shape without returning to their original form when the load is removed. Viscoplastic materials combine both viscous and plastic behaviors, showing time-dependent strain that increases under sustained stress, eventually leading to irreversible deformation. The key difference lies in viscoplasticity's rate-dependent flow and delayed deformation response, unlike purely plastic materials that deform instantaneously upon yielding.

Stress-Strain Relationships Explained

Plastic materials exhibit a distinct yield point in their stress-strain relationship, where deformation transitions from elastic to irreversible plastic flow, characterized by a constant stress level during strain hardening. Viscoplastic behavior combines both viscous and plastic deformation mechanisms, showing time-dependent strain under constant stress, modeled by constitutive equations incorporating rate sensitivity and internal state variables. Understanding the difference in stress-strain curves for plastic and viscoplastic materials is crucial in predicting material performance under varying load and time conditions, especially in metals and polymers used in structural applications.

Importance of Yield Point in Both Materials

The yield point signifies the stress level at which a material transitions from elastic to plastic deformation, critically influencing the behavior of both plastic and viscoplastic materials. In plastic materials, the yield point marks the start of irreversible deformation, essential for designing components that must withstand permanent shape changes. For viscoplastic materials, the yield point also involves time-dependent strain, making it crucial for predicting long-term material performance under sustained loading conditions.

Time-Dependent Deformation: Creep and Flow

Viscoplastic materials exhibit time-dependent deformation characterized by creep and flow under sustained stress, unlike purely plastic materials that deform instantly and remain static once the yield stress is exceeded. Creep in viscoplastic substances involves a gradual strain increase over time, influenced by temperature and applied stress, which impacts long-term structural integrity in engineering applications. Understanding viscoplastic behavior is essential for predicting material performance in components subjected to prolonged loading conditions, such as metals at high temperature or polymers under constant force.

Applications in Engineering and Industry

Plastic materials exhibit permanent deformation after yield and are commonly used in manufacturing structural components, packaging, and consumer goods due to their predictable load-bearing capacity. Viscoplastic materials combine both viscous and plastic behavior, making them ideal for applications in metal forming, soil mechanics, and polymer processing where time-dependent deformation and stress relaxation are critical factors. Engineering disciplines leverage plasticity theory for designing rigid parts, while viscoplastic models are essential in simulating creep behavior in aerospace turbine blades and geotechnical stability analysis.

Modeling and Simulation Techniques

Plastic and viscoplastic materials differ significantly in their stress-strain responses under loading, requiring distinct modeling and simulation techniques. Plasticity models typically use yield criteria, flow rules, and hardening laws to predict permanent deformation, while viscoplastic models incorporate time-dependent behavior through viscosity parameters and rate-dependent constitutive equations. Numerical methods such as finite element analysis implement these models, with viscoplastic simulations demanding more advanced algorithms to capture strain rate sensitivity and creep effects accurately.

Factors Influencing Material Selection

Material selection between plastic and viscoplastic substances depends heavily on mechanical behavior under stress and deformation rates. Plastics generally exhibit elastic or purely plastic behavior, making them suitable for applications with predictable loads, while viscoplastic materials show time-dependent strain, crucial for high-temperature or long-term load conditions. Key factors influencing choice include operating temperature, strain rate sensitivity, structural durability, and environmental exposure, ensuring optimal performance and longevity in engineering applications.

Future Trends in Plastic and Viscoplastic Research

Future trends in plastic and viscoplastic research emphasize advanced material modeling to improve predictive accuracy for complex deformation behaviors under varying thermal and mechanical conditions. Innovations in multiscale simulation techniques and machine learning integration are accelerating the development of new polymer composites with optimized viscoplastic properties for high-performance applications. Research also focuses on sustainable plastic materials featuring enhanced viscoplastic characteristics to meet environmental regulations and extend product lifespans.

Plastic Infographic

libterm.com

libterm.com