A contactor is an essential electrical device used to control the flow of electrical power in circuits, primarily for switching motors and lighting systems. It operates efficiently by providing a safe method to remotely switch high voltage loads with low voltage control signals, ensuring the protection of your equipment. Discover how contactors enhance system safety and performance by reading the rest of the article.

Table of Comparison

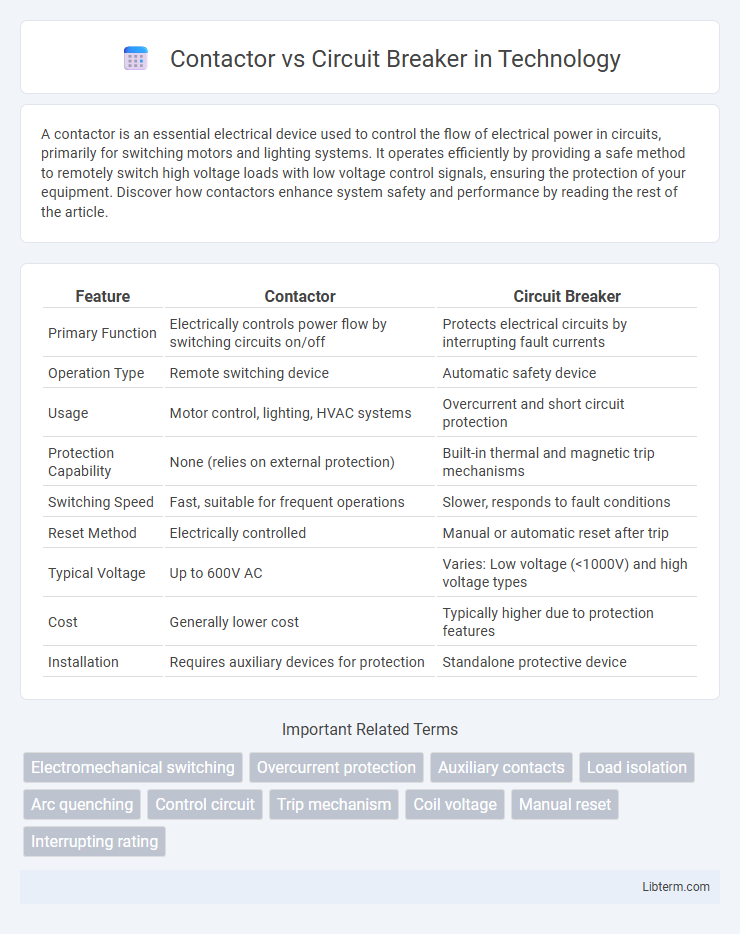

| Feature | Contactor | Circuit Breaker |

|---|---|---|

| Primary Function | Electrically controls power flow by switching circuits on/off | Protects electrical circuits by interrupting fault currents |

| Operation Type | Remote switching device | Automatic safety device |

| Usage | Motor control, lighting, HVAC systems | Overcurrent and short circuit protection |

| Protection Capability | None (relies on external protection) | Built-in thermal and magnetic trip mechanisms |

| Switching Speed | Fast, suitable for frequent operations | Slower, responds to fault conditions |

| Reset Method | Electrically controlled | Manual or automatic reset after trip |

| Typical Voltage | Up to 600V AC | Varies: Low voltage (<1000V) and high voltage types |

| Cost | Generally lower cost | Typically higher due to protection features |

| Installation | Requires auxiliary devices for protection | Standalone protective device |

Understanding Contactors and Circuit Breakers

Contactors are electromechanical switches designed to control high-power electrical circuits by making or breaking the connection based on control signals, commonly used for motor control and lighting systems. Circuit breakers provide essential overcurrent protection by automatically interrupting electrical flow during faults or overloads to prevent damage and ensure safety. Understanding the functional roles and operational mechanisms of contactors and circuit breakers is crucial for optimizing electrical system design and maintenance.

Key Differences Between Contactors and Circuit Breakers

Contactors are electromechanical switches designed for controlling power circuits by turning electrical loads on and off, while circuit breakers provide automatic protection by interrupting current flow in overload or short-circuit conditions. Contactors typically operate under normal load conditions without interrupting fault currents, whereas circuit breakers are engineered to detect and isolate faults to prevent damage and ensure safety. The main difference lies in functionality: contactors manage load switching, and circuit breakers manage circuit protection.

Primary Functions and Applications

Contactors primarily function as electrically controlled switches used to repeatedly make or break power circuits, commonly found in motor control applications and industrial automation systems. Circuit breakers serve as protective devices that automatically interrupt electrical flow during overloads or short circuits to prevent damage and ensure safety in residential, commercial, and industrial power distribution. While contactors enable controlled switching in high-current circuits, circuit breakers provide essential fault protection and overload prevention in electrical networks.

Working Principle of a Contactor

A contactor operates by using an electromagnetic coil to create a magnetic field that pulls in a set of contacts, allowing current to flow in a controlled electrical circuit. When the coil is de-energized, a spring mechanism returns the contacts to their original open state, interrupting the current. This working principle enables contactors to switch high-power loads remotely with fast and reliable response, unlike circuit breakers which primarily protect circuits by interrupting current during fault conditions.

Working Principle of a Circuit Breaker

A circuit breaker operates by automatically interrupting current flow in an electrical circuit when a fault, such as an overload or short circuit, is detected, using an internal switching mechanism triggered by thermal or magnetic sensors. The thermal sensor reacts to excessive current by bending a bimetallic strip, while the magnetic sensor responds to sudden surges by activating an electromagnet that trips the breaker. This rapid disconnection protects electrical equipment and prevents potential hazards like fires or equipment damage.

Advantages and Limitations of Contactors

Contactors offer advantages such as remote control capability, high switching speed, and the ability to handle frequent switching operations in electrical circuits. Their limitations include susceptibility to contact wear and limited protection capabilities compared to circuit breakers, which provide overload and short-circuit protection. Contactors are ideal for controlling electric motors and lighting circuits but require complementary protective devices for comprehensive safety.

Pros and Cons of Circuit Breakers

Circuit breakers offer superior protection by automatically interrupting electrical flow during overloads or short circuits, minimizing potential damage to wiring and connected devices. They provide easy reset capabilities without the need for replacement, enhancing operational convenience and reducing maintenance costs. However, circuit breakers can be more expensive upfront compared to fuses or contactors and may require periodic testing to ensure reliable performance.

Selection Criteria: Contactor vs Circuit Breaker

Contactor selection centers on managing high-frequency switching and controlling large electrical loads in motor and lighting circuits, emphasizing coil voltage, contact rating, and switching capacity. Circuit breaker selection prioritizes overcurrent protection, short-circuit interrupting capacity, and breaking capacity to prevent electrical faults and ensure system safety. Choosing between a contactor and circuit breaker depends on application requirements, with contactors ideal for control and automation, while circuit breakers offer essential protection and fault isolation in electrical systems.

Safety Considerations in Electrical Installations

Contactors and circuit breakers serve distinct safety roles in electrical installations, with contactors primarily managing controlled switching of electrical circuits and circuit breakers providing essential overcurrent protection to prevent electrical fires and equipment damage. Circuit breakers detect faults such as short circuits or overloads and automatically interrupt the current flow, ensuring electrical safety by minimizing risks of shock and overheating. Contactors, while not designed to interrupt fault currents, are used in tandem with protective devices like circuit breakers to maintain safe operation of motors and heavy electrical loads.

Choosing the Right Device for Your Needs

Selecting the right device between a contactor and a circuit breaker depends on the application requirements, such as load control and protection. Contactors are ideal for switching high-current electrical circuits in motor control systems, offering efficient remote operation. Circuit breakers provide essential protection by interrupting power during overloads or short circuits, ensuring safety and preventing damage.

Contactor Infographic

libterm.com

libterm.com