RFID technology uses radio waves to automatically identify and track tags attached to objects, enhancing inventory management and supply chain efficiency. It offers real-time data collection and reduces human error, making it indispensable in various industries. Discover how RFID can transform your operations by reading the full article.

Table of Comparison

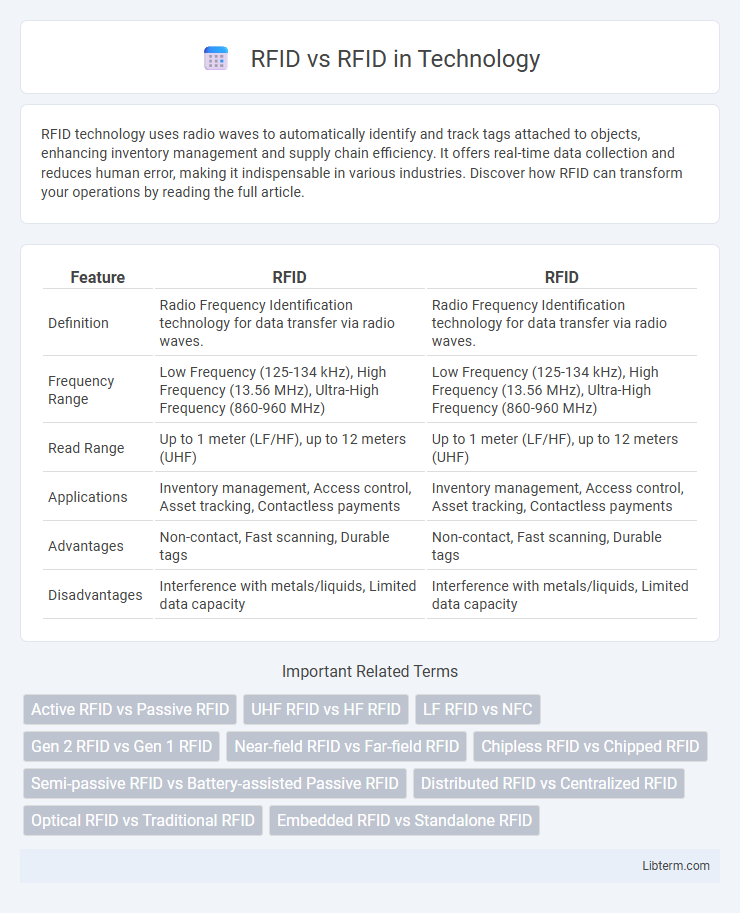

| Feature | RFID | RFID |

|---|---|---|

| Definition | Radio Frequency Identification technology for data transfer via radio waves. | Radio Frequency Identification technology for data transfer via radio waves. |

| Frequency Range | Low Frequency (125-134 kHz), High Frequency (13.56 MHz), Ultra-High Frequency (860-960 MHz) | Low Frequency (125-134 kHz), High Frequency (13.56 MHz), Ultra-High Frequency (860-960 MHz) |

| Read Range | Up to 1 meter (LF/HF), up to 12 meters (UHF) | Up to 1 meter (LF/HF), up to 12 meters (UHF) |

| Applications | Inventory management, Access control, Asset tracking, Contactless payments | Inventory management, Access control, Asset tracking, Contactless payments |

| Advantages | Non-contact, Fast scanning, Durable tags | Non-contact, Fast scanning, Durable tags |

| Disadvantages | Interference with metals/liquids, Limited data capacity | Interference with metals/liquids, Limited data capacity |

Understanding RFID: An Overview

RFID (Radio Frequency Identification) uses electromagnetic fields to automatically identify and track tags attached to objects, enabling efficient inventory management and asset tracking. Passive RFID tags derive power from the reader's signal, offering cost-effective solutions for short-range applications, while active RFID tags contain their own power source, providing longer read ranges and enhanced functionality. Understanding the distinction between passive and active RFID systems is essential for optimizing implementation in industries such as logistics, retail, and manufacturing.

Types of RFID Systems: Passive vs. Active

Passive RFID systems rely on tags that draw power from the RFID reader's electromagnetic field, offering cost-effective solutions for short-range applications such as inventory tracking and access control. Active RFID systems utilize battery-powered tags that actively transmit signals, enabling longer read ranges and real-time location tracking in environments like asset management and supply chain logistics. The choice between passive and active RFID depends on factors like range, tag lifespan, cost, and application requirements.

Key Components of RFID Technology

RFID technology consists primarily of three key components: the RFID tag, the RFID reader, and the antenna. The RFID tag stores unique identification data and can be passive, active, or semi-passive, impacting read range and power requirements. The RFID reader emits radio waves through the antenna to communicate with the tag, process the data, and interface with backend systems for accurate real-time tracking and inventory management.

RFID Frequencies: LF, HF, and UHF Compared

RFID frequencies are categorized into Low Frequency (LF), High Frequency (HF), and Ultra High Frequency (UHF), each optimized for specific applications and environments. LF RFID operates around 125-134 kHz with short read ranges up to 10 cm and is ideal for animal tracking and access control due to its interference resistance. HF RFID at 13.56 MHz offers moderate read ranges up to 1 meter and is widely used in smart cards, contactless payments, and library systems, while UHF RFID, ranging from 300 MHz to 3 GHz (commonly 860-960 MHz), provides long read distances up to 12 meters with faster data transfer rates, making it preferred for supply chain management and asset tracking.

Performance Comparison: Range, Speed, and Accuracy

RFID performance varies significantly based on frequency bands: Low Frequency (LF) offers limited range up to 10 cm with slower data transfer but high accuracy in metal and wet environments, while High Frequency (HF) provides moderate range around 1 meter with faster speeds and good accuracy for access control. Ultra-High Frequency (UHF) RFID achieves ranges up to 12 meters with rapid data transfer rates, ideal for inventory tracking but prone to interference and reduced accuracy near metals or liquids. In terms of accuracy and speed, UHF tags excel in bulk reading scenarios, whereas LF and HF tags perform better in precision-required single-tag reads within shorter distances.

Security Features: Protecting RFID Data

RFID systems employ multiple security features such as encryption, mutual authentication, and secure key management to protect data from unauthorized access and cloning. Advanced protocols like AES encryption safeguard the communication between RFID tags and readers, preventing eavesdropping and data interception. Implementing tamper-resistant hardware and access control mechanisms further enhances the protection of sensitive RFID data in high-security environments.

Cost Analysis: Implementation and Maintenance

RFID systems vary widely in cost depending on the type of tags--passive RFID tags typically cost between $0.10 and $0.50 each, while active RFID tags can range from $10 to $50 per tag, significantly impacting implementation expenses. Maintenance costs for passive RFID are generally lower due to the absence of batteries, whereas active RFID requires periodic battery replacement and more complex upkeep, increasing long-term expenses. The total cost of ownership should include initial hardware, software, installation, and ongoing support, with passive RFID presenting a more cost-effective solution for large-scale inventory management compared to active RFID's higher investment suitable for real-time tracking in dynamic environments.

Practical Applications: Use Cases Across Industries

RFID technology enables seamless asset tracking in healthcare, improving inventory management for medical supplies and equipment. In logistics, RFID streamlines supply chain operations by providing real-time visibility into shipment locations and status. Retail leverages RFID for inventory accuracy and loss prevention, enhancing customer experience through efficient stock management and faster checkout processes.

Scalability and Integration Challenges

RFID scalability depends on the system's ability to handle increased tag volume and data traffic without performance degradation, with passive RFID systems generally offering easier scalability due to lower costs and simpler infrastructure. Integration challenges arise when RFID technology must be incorporated into existing IT frameworks, often requiring customized middleware and compatibility adjustments to ensure seamless data flow and interoperability. Enterprise-scale deployments demand robust network architecture and standardized protocols to overcome latency issues and maintain real-time tracking accuracy.

Future Trends in RFID Technology

Future trends in RFID technology emphasize increased integration with the Internet of Things (IoT), enhancing real-time data collection and asset tracking across industries. Advances in chip miniaturization and energy-efficient passive RFID tags are expected to boost adoption in healthcare, retail, and supply chain management. Emerging innovations in RFID security protocols aim to address privacy concerns and improve data encryption for more reliable, scalable deployments.

RFID Infographic

libterm.com

libterm.com