Effective support enhances user satisfaction by resolving issues promptly and providing clear, helpful guidance. Investing in responsive customer service channels ensures your audience feels valued and confident in your brand. Discover the key strategies to elevate your support system in the rest of the article.

Table of Comparison

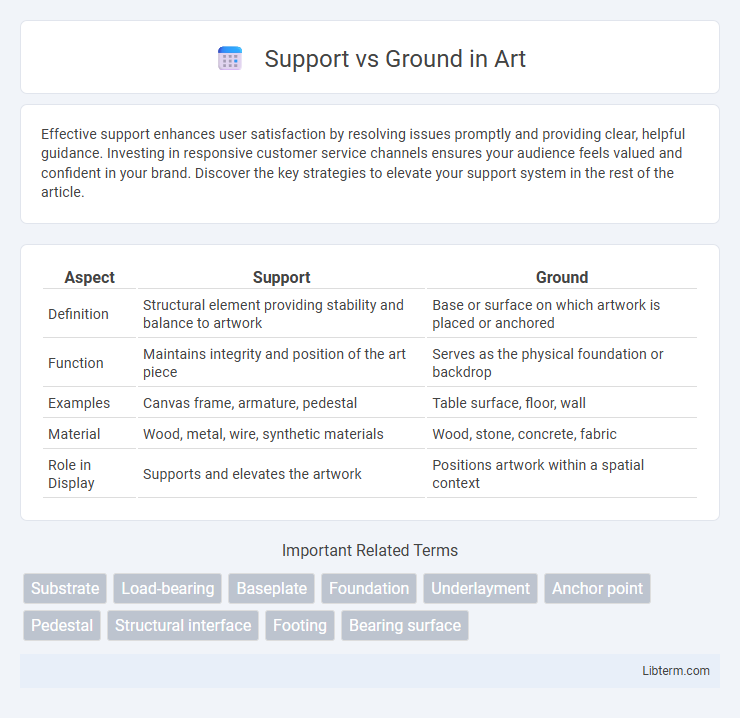

| Aspect | Support | Ground |

|---|---|---|

| Definition | Structural element providing stability and balance to artwork | Base or surface on which artwork is placed or anchored |

| Function | Maintains integrity and position of the art piece | Serves as the physical foundation or backdrop |

| Examples | Canvas frame, armature, pedestal | Table surface, floor, wall |

| Material | Wood, metal, wire, synthetic materials | Wood, stone, concrete, fabric |

| Role in Display | Supports and elevates the artwork | Positions artwork within a spatial context |

Understanding Support and Ground: Key Differences

Support refers to an electrical connection that carries current and powers devices, typically represented by hot or live wires in circuits. Ground acts as a safety path designed to carry fault current away from electrical devices, preventing electric shock and equipment damage. Understanding the difference ensures proper wiring practices, enhances circuit protection, and maintains overall electrical safety compliance.

The Importance of Electrical Grounding

Electrical grounding ensures safety by providing a low-resistance path for fault currents, preventing electric shock and equipment damage. Unlike structural support components, grounding connects electrical systems directly to the earth, stabilizing voltage levels and enabling the operation of protective devices like circuit breakers. Effective grounding minimizes electrical noise, reduces the risk of fire, and maintains system reliability in residential, commercial, and industrial installations.

Types of Support in Electrical Systems

Types of support in electrical systems include neutral support, ground support, and floating support, each serving distinct roles in circuit safety and functionality. Ground support provides a direct path to earth, preventing electric shock and equipment damage by stabilizing voltage levels. Neutral support acts as a return path for current, maintaining electrical balance, while floating support isolates certain components to prevent unintended currents and interference.

Functions of a Ground Connection

A ground connection functions as a safety path that directs excess electrical current away from circuits to prevent electric shock and equipment damage. It stabilizes voltage levels by providing a common reference point, ensuring consistent system operation. Grounding also minimizes electromagnetic interference, enhancing signal integrity and overall electrical performance.

Mechanical Support vs Electrical Ground: Clear Distinctions

Mechanical support refers to the structural components that securely hold or position electrical devices and wiring, ensuring physical stability and safety. Electrical ground, on the other hand, is a conductive connection that provides a zero-voltage reference point to safely dissipate fault currents and prevent electrical shock hazards. Understanding the distinction between mechanical support and electrical ground is crucial for effective electrical system design, ensuring both physical integrity and electrical safety compliance.

Common Applications for Support and Ground

Support structures typically provide mechanical stability and hold electrical components in place, crucial in power transmission towers and equipment mounting in industrial settings. Grounding systems ensure electrical safety by redirecting fault currents away from equipment and personnel, commonly used in residential wiring, electronic circuit protection, and lightning protection setups. Combining support with grounding enhances both structural integrity and safety in electrical and construction applications.

Safety Implications: Support vs Ground

Support and ground serve distinct roles in electrical systems, with support primarily providing mechanical stability and ground ensuring electrical safety by offering a low-resistance path for fault currents. Proper grounding minimizes shock hazards and equipment damage by safely dissipating electrical faults into the earth, whereas inadequate grounding can lead to dangerous voltage buildup. Differentiating between support structures and grounding conductors is crucial to maintain system integrity and protect both people and equipment from electrical hazards.

Materials Used for Support and Ground

Support materials are typically non-conductive substances such as fiberglass, plastic composites, or ceramic materials that provide structural stability and insulation in electrical systems. Ground materials predominantly consist of conductive metals like copper, aluminum, or galvanized steel, chosen for their excellent electrical conductivity and corrosion resistance to ensure effective grounding. The choice of these materials directly influences the safety, durability, and efficiency of electrical installations.

Installation Best Practices for Support and Ground

Proper installation of support and ground systems is critical for electrical safety and system reliability. Supports should be securely anchored and made of non-corrosive materials to maintain structural integrity, while grounding conductors must be sized according to NEC guidelines to ensure effective fault current dissipation. Regular inspection and adherence to manufacturer specifications help prevent loose connections and potential electrical hazards.

Troubleshooting Issues Related to Support and Ground

Support and ground wires play crucial roles in electrical safety, with support typically referring to the structural elements holding wiring in place and ground serving as a safety path for fault current. Troubleshooting issues related to support often involves checking for loose or damaged clamps, insulation wear, or inadequate wire tension that can cause mechanical stress or interference. Grounding problems usually stem from corrosion, broken connections, or improper grounding rod installation, resulting in ineffective fault current dissipation and increased risk of electrical shock or equipment damage.

Support Infographic

libterm.com

libterm.com