Casting is a pivotal process in manufacturing where molten material is poured into a mold to create complex shapes with precise details. This technique enables the production of components with high strength and durability, essential for industries like automotive and aerospace. Discover how casting can enhance your projects and explore its various methods in the full article.

Table of Comparison

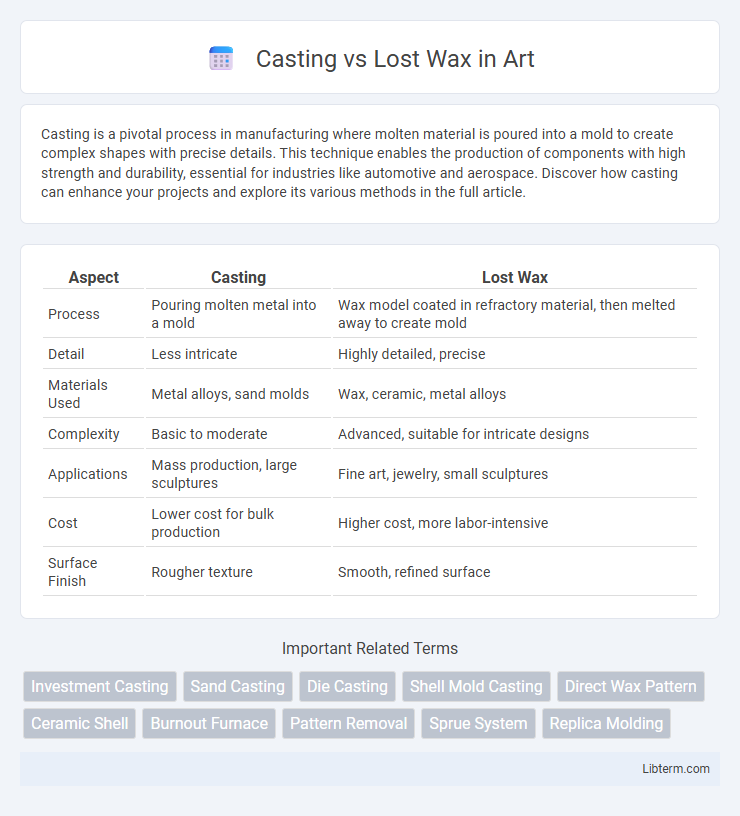

| Aspect | Casting | Lost Wax |

|---|---|---|

| Process | Pouring molten metal into a mold | Wax model coated in refractory material, then melted away to create mold |

| Detail | Less intricate | Highly detailed, precise |

| Materials Used | Metal alloys, sand molds | Wax, ceramic, metal alloys |

| Complexity | Basic to moderate | Advanced, suitable for intricate designs |

| Applications | Mass production, large sculptures | Fine art, jewelry, small sculptures |

| Cost | Lower cost for bulk production | Higher cost, more labor-intensive |

| Surface Finish | Rougher texture | Smooth, refined surface |

Introduction to Casting and Lost Wax Techniques

Casting involves pouring molten metal into a mold to create precise shapes, a technique commonly used in industrial manufacturing for complex parts. Lost wax casting, an ancient method, uses a wax model coated with a refractory material to form a mold; once the wax melts away, molten metal fills the cavity, enabling high-detail jewelry and sculpture production. Both techniques offer distinct advantages in producing metal objects, with lost wax casting excelling in fine detail and traditional casting favored for mass production.

Historical Background of Metal Casting

The historical background of metal casting dates back over 5,000 years, with lost wax casting being one of the earliest and most intricate methods used by ancient civilizations such as the Egyptians and Mesopotamians. Lost wax casting involves creating a detailed wax model that is coated in a refractory material to form a mold, which is then heated to melt away the wax before molten metal is poured in, allowing for high precision in complex designs. Traditional casting methods, including sand casting and investment casting, have evolved alongside lost wax techniques, reflecting advancements in metallurgy and craftsmanship throughout history.

What is Lost Wax Casting?

Lost wax casting, also known as investment casting, is a precise metal casting process where a wax model is coated with a ceramic shell that hardens to form a mold; the wax is then melted away, leaving a cavity for molten metal to be poured in. This technique enables the production of intricate and detailed components, commonly used in jewelry, aerospace, and art manufacturing. Compared to traditional casting methods, lost wax casting offers superior accuracy and fine surface finishes for complex shapes.

Key Differences: Casting vs Lost Wax

Casting involves pouring molten metal into a mold to create a desired shape, while lost wax casting specifically uses a wax model coated with a refractory material to form a mold that is melted away before metal is poured. Key differences include the precision and detail achievable; lost wax casting excels in producing intricate designs and fine details compared to traditional casting methods. Lost wax casting also offers greater versatility in metal types and is commonly used for jewelry, art sculptures, and complex mechanical parts due to its superior accuracy.

Materials Used in Both Techniques

Casting involves melting metals such as aluminum, bronze, and steel, which are poured into molds made from sand, metal, or ceramic materials. Lost wax casting uses a wax model encased in refractory materials like silica, plaster, or ceramic to create molds that capture fine details before the wax is melted away and replaced by molten metal. Both techniques rely heavily on heat-resistant mold materials but differ in their initial model substances and precision capabilities.

Step-by-Step Process: Standard Casting

Standard casting involves creating a mold by pouring molten metal into a prepared cavity, typically made from sand, ceramic, or metal. The process starts by melting the metal to a precise temperature, followed by pouring it into the mold to solidify into the desired shape. After cooling, the casting is removed, cleaned, and finished through grinding or machining to achieve the final product specifications.

Step-by-Step Process: Lost Wax Casting

Lost wax casting begins by sculpting a detailed wax model, which is then coated with a ceramic slurry to form a heat-resistant mold. After the mold hardens, the wax is melted away in a kiln, leaving a cavity for molten metal to be poured. Once the metal cools and solidifies, the ceramic shell is broken away to reveal the final metal casting, followed by cleaning and finishing steps to achieve the desired detail and surface quality.

Advantages of Lost Wax Casting

Lost wax casting offers exceptional precision and intricate detail replication, making it ideal for complex metal components and fine jewelry. This method enables high-quality surface finishes and consistent dimensional accuracy, reducing the need for extensive post-processing. It also allows for efficient production of small to medium-sized batches, optimizing material use and minimizing waste.

Limitations and Challenges of Each Method

Casting methods face limitations such as lower precision and surface finish compared to lost wax techniques, often resulting in rougher textures and dimensional inaccuracies. Lost wax casting, while offering high detail and complex shapes, presents challenges including longer production times, higher costs, and potential defects like porosity or incomplete wax removal. Both methods require careful control of temperature and material properties to minimize issues like shrinkage and warping during solidification.

Which Technique to Choose: Applications and Recommendations

Lost wax casting offers superior detail and surface finish, making it ideal for intricate jewelry, art pieces, and precision components. Traditional casting methods suit larger, less detailed parts where speed and cost-efficiency are prioritized over fine resolution. Selecting the right technique depends on project complexity, material type, production volume, and budget constraints, with lost wax favored for high-detail and small batch productions.

Casting Infographic

libterm.com

libterm.com