Direct Metal Laser Sintering (DMLS) is an advanced additive manufacturing technique that creates highly detailed metal parts layer by layer using a laser to fuse metal powder. This process allows for complex geometries and strong, durable components typically used in aerospace, automotive, and medical industries. Explore the rest of the article to discover how DMLS can revolutionize your metal fabrication projects.

Table of Comparison

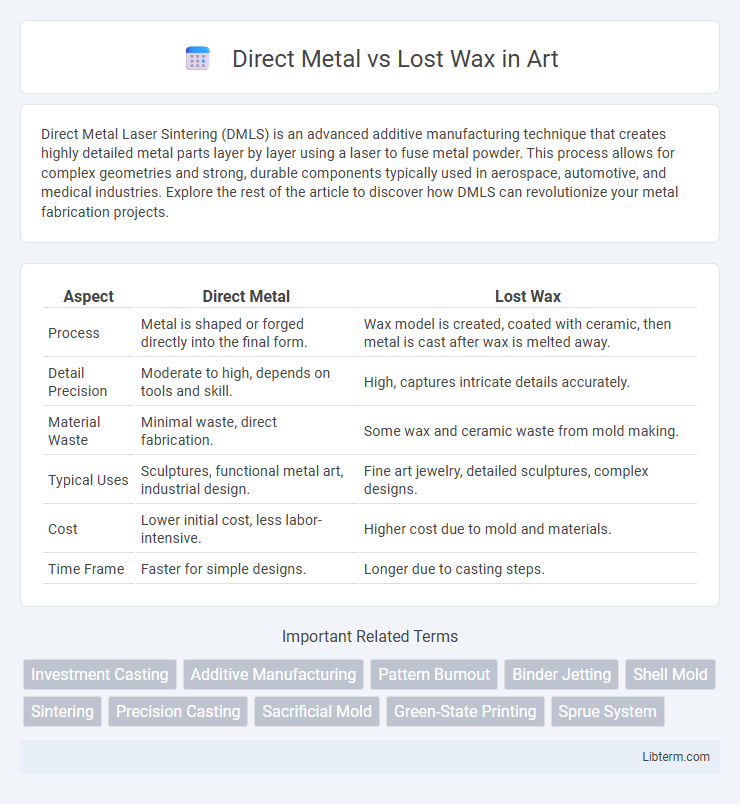

| Aspect | Direct Metal | Lost Wax |

|---|---|---|

| Process | Metal is shaped or forged directly into the final form. | Wax model is created, coated with ceramic, then metal is cast after wax is melted away. |

| Detail Precision | Moderate to high, depends on tools and skill. | High, captures intricate details accurately. |

| Material Waste | Minimal waste, direct fabrication. | Some wax and ceramic waste from mold making. |

| Typical Uses | Sculptures, functional metal art, industrial design. | Fine art jewelry, detailed sculptures, complex designs. |

| Cost | Lower initial cost, less labor-intensive. | Higher cost due to mold and materials. |

| Time Frame | Faster for simple designs. | Longer due to casting steps. |

Introduction to Direct Metal and Lost Wax Casting

Direct metal casting involves pouring molten metal directly into a mold to create precise and durable components, commonly used in industries like aerospace and automotive manufacturing. Lost wax casting, also known as investment casting, uses a wax model coated with ceramic material to form a detailed mold, producing complex shapes with excellent surface finish and dimensional accuracy. Both methods excel in applications requiring high-quality metal parts, but differ in process complexity, cost, and suitability for intricate designs.

Overview of the Direct Metal Process

The Direct Metal process involves the use of advanced 3D printing technology to create precise metal parts layer by layer directly from digital files, eliminating the need for molds. This method utilizes metal powders fused by lasers or electron beams to build components with high accuracy, complex geometries, and superior mechanical properties. It offers faster production times and reduced material waste compared to traditional Lost Wax casting techniques.

Understanding the Lost Wax Casting Method

The Lost Wax Casting method involves creating a detailed wax model, which is then encased in a refractory material to form a mold; the wax is melted away, leaving a cavity for molten metal to be poured into, capturing fine details with high precision. This process contrasts with direct metal casting, where the metal is poured directly into a mold without a wax model, often resulting in less intricate designs. Lost Wax Casting excels in producing complex geometries and smooth surface finishes, making it ideal for jewelry, intricate art pieces, and precise industrial components.

Materials Used in Direct Metal vs Lost Wax

Direct metal casting primarily utilizes metals such as aluminum, stainless steel, and titanium, allowing for high-strength, durable parts with precise dimensions. Lost wax casting employs wax patterns that are replaced by molten metals like bronze, gold, or silver to produce intricate and detailed components. The choice of materials influences the casting method's suitability for applications demanding either robustness or fine artistic detail.

Precision and Detail: Comparing Results

Direct metal 3D printing offers remarkable precision with layer resolutions typically as fine as 20 microns, enabling intricate geometries and sharp edges ideal for aerospace and medical applications. Lost wax casting excels in capturing organic details and complex surface textures due to its mold-based process, but generally achieves slightly lower dimensional accuracy compared to direct metal printing, with tolerances around +-0.1 mm. While direct metal printing ensures consistent high-resolution detail directly from digital files, lost wax remains preferred for ultra-fine artistic features and smooth finishes on small batch projects.

Speed and Efficiency in Production

Direct Metal Laser Sintering (DMLS) offers faster production cycles compared to Lost Wax casting due to its layer-by-layer additive manufacturing process, eliminating the need for mold creation and wax burnout. Lost Wax casting involves multiple time-consuming steps, including wax model fabrication, investment molds, and furnace cycles, which extend overall production time. DMLS enables rapid prototyping and small-batch production with minimal post-processing, significantly enhancing efficiency for complex metal parts.

Cost Implications of Both Methods

Direct metal 3D printing typically incurs higher upfront costs due to advanced equipment and material expenses but can reduce labor and tooling costs over time. Lost wax casting involves lower initial investment but often leads to higher per-unit costs because of labor-intensive mold preparation and wax model creation. Businesses must weigh the balance between initial capital expenditure and long-term production volume to determine cost efficiency.

Suitability for Complex Designs

Direct metal 3D printing offers superior suitability for complex designs due to its layer-by-layer additive process, enabling intricate geometries and internal structures that traditional lost wax casting struggles to replicate. Lost wax casting can achieve high detail but is limited by mold complexities and design constraints, often requiring multiple steps to produce delicate features. For applications demanding precise internal channels, undercuts, or complex lattice frameworks, direct metal printing provides unmatched versatility and accuracy.

Environmental Impact and Sustainability

Direct metal 3D printing minimizes material waste by using precise additive processes, reducing scrap rates compared to the lost wax casting method, which involves additional steps such as wax mold creation and melting, generating higher energy consumption and waste. Lost wax casting relies on disposable molds and consumes significant amounts of energy during wax melting and metal pouring, contributing to environmental pollution and resource depletion. Sustainable manufacturing trends favor direct metal techniques for their efficiency in material usage, lower carbon footprint, and reduced hazardous waste production.

Choosing the Right Method for Your Project

Choosing between Direct Metal and Lost Wax casting depends on project complexity, material type, and desired surface finish. Direct Metal casting is ideal for rapid production with durable metals like steel and aluminum, offering strength and precision in larger, less intricate designs. Lost Wax casting excels in creating highly detailed pieces with complex geometries, commonly used for precious metals such as gold and silver, delivering superior surface smoothness and fine detailing.

Direct Metal Infographic

libterm.com

libterm.com