Digital print technology revolutionizes traditional printing by enabling fast, high-quality, and cost-effective production of customized materials. Your brand can benefit from vibrant colors, sharp details, and the flexibility to print on various substrates without the need for extensive setup or plates. Discover how digital print can transform your marketing strategy by reading the rest of the article.

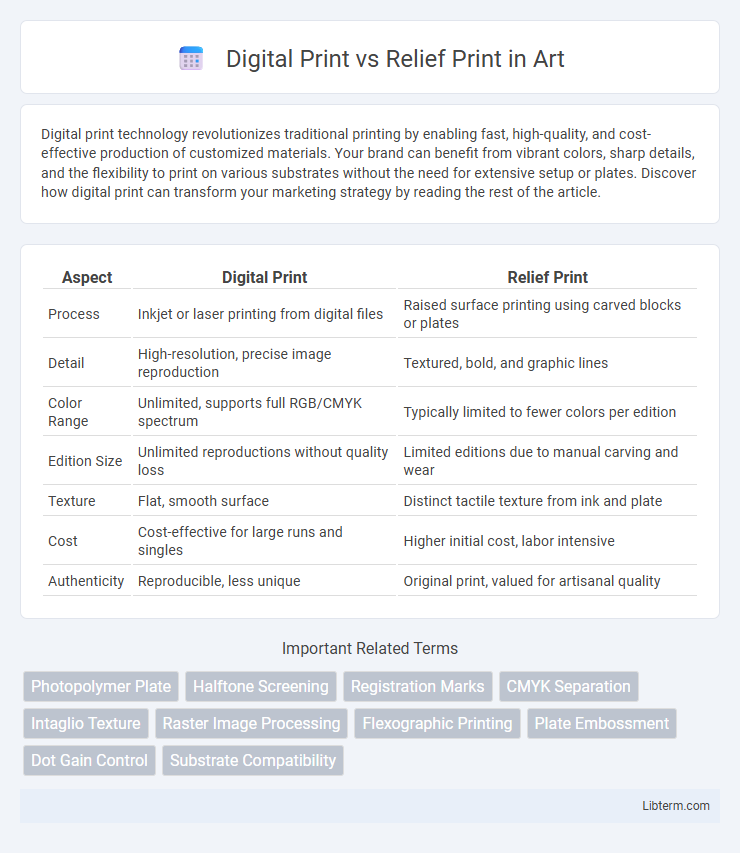

Table of Comparison

| Aspect | Digital Print | Relief Print |

|---|---|---|

| Process | Inkjet or laser printing from digital files | Raised surface printing using carved blocks or plates |

| Detail | High-resolution, precise image reproduction | Textured, bold, and graphic lines |

| Color Range | Unlimited, supports full RGB/CMYK spectrum | Typically limited to fewer colors per edition |

| Edition Size | Unlimited reproductions without quality loss | Limited editions due to manual carving and wear |

| Texture | Flat, smooth surface | Distinct tactile texture from ink and plate |

| Cost | Cost-effective for large runs and singles | Higher initial cost, labor intensive |

| Authenticity | Reproducible, less unique | Original print, valued for artisanal quality |

Introduction to Digital and Relief Printing

Digital printing utilizes digital files to produce images directly onto various substrates using inkjet or laser technology, offering high precision and fast turnaround times ideal for short runs and customized prints. Relief printing, one of the oldest printing techniques, involves carving images into a surface such as wood or linoleum, where raised areas are inked and pressed onto paper, producing distinct textures and rich detail. Both methods serve unique purposes: digital print excels in efficiency and color accuracy, while relief print emphasizes artisanal quality and tactile depth.

Understanding Digital Printing: Definition and Process

Digital printing is a modern printing technique that uses digital files to produce images directly onto various substrates without the need for printing plates. The process involves technologies such as inkjet and laser printing, where tiny droplets of ink or toner are precisely applied to paper, fabric, or other materials based on digital data. This method offers high-speed production, cost-effectiveness for short runs, and the flexibility to easily customize each print.

Exploring Relief Printing: Definition and History

Relief printing, a traditional printmaking technique dating back to ancient Mesopotamia around 3000 BCE, involves carving an image into a surface such as wood or linoleum, where the raised areas are inked and pressed onto paper. This method contrasts with digital printing, which uses electronic templates and inkjet or laser technology for faster production and more precise color control. Understanding relief printing's historical significance highlights its artisanal value, characterized by the tactile quality and unique textures achieved through manual craftsmanship.

Key Differences Between Digital and Relief Printing

Digital print utilizes inkjet or laser technology to produce high-resolution images directly from a digital file, enabling rapid production and easy customization without the need for physical plates. Relief printing involves carving an image onto a surface, such as wood or linoleum, where the raised areas transfer ink onto paper, producing textured and tactile prints with a handcrafted quality. Key differences include digital print's speed and versatility versus relief print's artisanal texture and traditional craftsmanship.

Advantages of Digital Print Technology

Digital print technology offers superior versatility by enabling fast turnaround times and lower costs for short print runs compared to relief printing. It provides high-resolution images with precise color matching and allows for easy customization without the need for physical plates. This technology supports on-demand printing, reducing waste and inventory needs while maintaining consistent quality across multiple copies.

Benefits of Traditional Relief Printing

Traditional relief printing offers unmatched tactile quality and depth, creating rich textures that digital prints often lack. Its hands-on process allows for intricate detail and unique imperfections, enhancing artistic authenticity. Relief printing also requires minimal technology, making it accessible and affordable for small studios and artisans.

Limitations of Digital Printing Methods

Digital printing faces limitations such as lower durability and color vibrancy compared to relief printing, as it relies on toner or inkjet technology that may fade over time. The resolution and texture detail achievable in relief printing, which involves carving or etching, surpass the often flatter and less tactile results of digital methods. Additionally, digital printing struggles with textured or uneven surfaces where traditional relief print presses can apply consistent pressure for clearer impressions.

Challenges of Relief Printing Techniques

Relief printing techniques face challenges like limited resolution and color complexity compared to digital print, which supports finer details and a broader color gamut. The manual nature of relief printing leads to inconsistencies and longer production times, restricting large-scale or highly detailed projects. Material limitations and wear of printing blocks also impact the durability and repeatability of relief prints compared to the precision and efficiency offered by digital printing technologies.

Choosing the Right Printing Method for Your Project

Digital print offers high precision, vibrant colors, and rapid turnaround, making it ideal for detailed images and short runs. Relief print excels in texture, durability, and tactile appeal, often preferred for artisanal or limited-edition projects. Assess project goals--such as quantity, material, and design complexity--to select the optimal printing method.

Future Trends in Printing: Digital vs Relief

Future trends in printing reveal a strong shift towards digital print due to its ability to deliver high-resolution images with quick turnaround times and customizable options, making it ideal for short runs and on-demand production. Relief printing, known for its tactile quality and traditional craftsmanship, maintains a niche market in luxury packaging and art prints but faces limitations in speed and scalability. Innovations in digital ink and substrate compatibility suggest continued dominance of digital print technology, while relief printing evolves through hybrid techniques integrating digital elements to meet modern design demands.

Digital Print Infographic

libterm.com

libterm.com