OEM, or Original Equipment Manufacturer, refers to companies that produce parts or equipment used in another company's end product. Understanding OEM can help you identify authentic components that ensure quality and compatibility in your purchases. Explore the rest of this article to learn how OEM impacts savings, performance, and reliability.

Table of Comparison

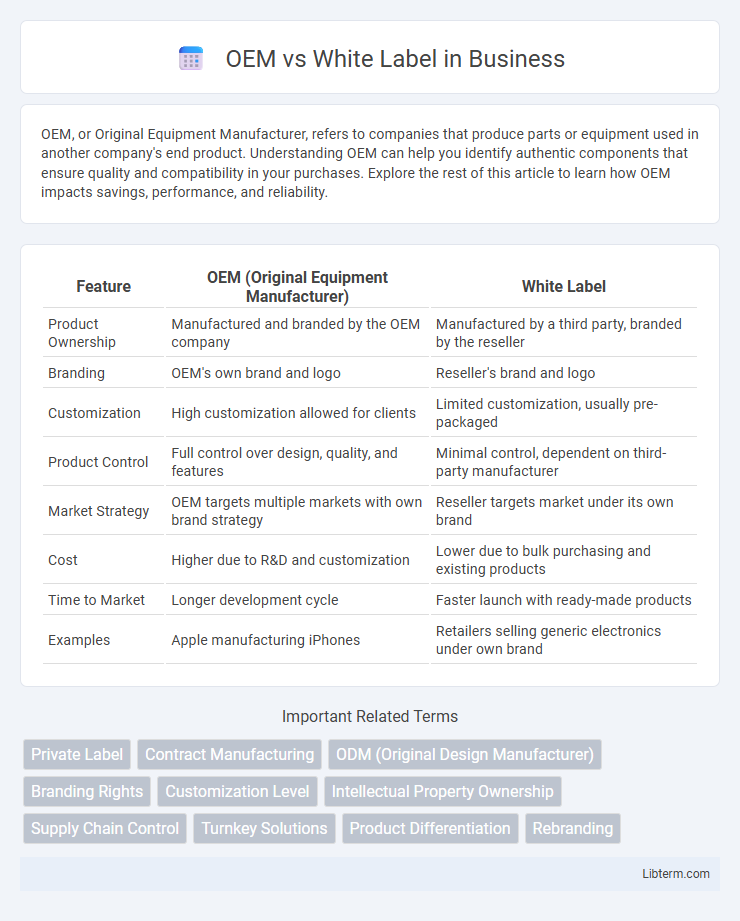

| Feature | OEM (Original Equipment Manufacturer) | White Label |

|---|---|---|

| Product Ownership | Manufactured and branded by the OEM company | Manufactured by a third party, branded by the reseller |

| Branding | OEM's own brand and logo | Reseller's brand and logo |

| Customization | High customization allowed for clients | Limited customization, usually pre-packaged |

| Product Control | Full control over design, quality, and features | Minimal control, dependent on third-party manufacturer |

| Market Strategy | OEM targets multiple markets with own brand strategy | Reseller targets market under its own brand |

| Cost | Higher due to R&D and customization | Lower due to bulk purchasing and existing products |

| Time to Market | Longer development cycle | Faster launch with ready-made products |

| Examples | Apple manufacturing iPhones | Retailers selling generic electronics under own brand |

Understanding OEM: Definition and Key Features

OEM (Original Equipment Manufacturer) refers to companies that produce components or products which are rebranded and sold by another company. Key features of OEM include customization options, control over design specifications, and direct manufacturing for client brands. OEM products typically maintain the manufacturing company's quality standards while allowing the purchasing brand to offer unique, branded products without developing them from scratch.

What is White Label? An Overview

White Label products are pre-manufactured goods produced by one company and rebranded by another to appear as their own, allowing brands to quickly enter the market without investing in product development. Unlike OEM (Original Equipment Manufacturer), which customizes products to client specifications, White Label solutions offer standardized items with customizable packaging and branding. This approach streamlines production costs, reduces time-to-market, and leverages existing manufacturing expertise for businesses seeking turnkey product offerings.

Core Differences Between OEM and White Label

OEM (Original Equipment Manufacturer) provides products designed and manufactured by one company that another company brands and sells under its own name, often allowing customization of hardware or software. White label products are generic items produced by one company and sold to multiple retailers, who rebrand them without altering the core product. The core difference lies in OEM enabling tailored modifications and exclusive branding, whereas white label products offer standardized goods for broad rebranding opportunities.

Business Benefits of OEM Solutions

OEM solutions offer businesses the advantage of customized product integration, allowing companies to enhance their brand identity without investing heavily in product development. By leveraging OEM partnerships, businesses can accelerate time-to-market and reduce operational costs through scalable manufacturing processes. This strategic approach supports competitive differentiation and drives higher profit margins by delivering tailored, high-quality products aligned with customer demands.

Advantages of White Label Products

White label products offer significant advantages by allowing businesses to quickly enter the market with pre-manufactured goods branded under their own name, saving time and reducing development costs. They provide flexibility in branding and customization, enabling companies to tailor packaging, marketing, and product features to better meet their target audience's preferences. This approach minimizes production risks and inventory management challenges while maximizing profit margins through efficient scale and established supply chains.

Customization: OEM vs White Label Approaches

OEM (Original Equipment Manufacturer) products offer extensive customization options, allowing businesses to modify design, features, and branding to create a unique product tailored to specific market needs. White label products provide limited customization, primarily focusing on branding and packaging changes while maintaining the core product's original design and features. OEM solutions are ideal for companies seeking full control over product development, whereas white label is suited for quick market entry with minimal product alteration.

Brand Control and Ownership Considerations

OEM products provide manufacturers with limited brand control as the product is designed and produced by another company, restricting customization options and ownership rights. White label products offer complete brand ownership, allowing companies to market the product under their own brand name with full control over branding, packaging, and customer experience. Businesses seeking strong brand identity and intellectual property rights typically prefer white labeling to maintain direct control over their market presence.

Cost Implications: OEM vs White Label

OEM products generally incur higher upfront costs due to custom design, manufacturing specifications, and brand integration, making them a larger initial investment compared to white label options. White label products benefit from economies of scale as manufacturers produce a standardized product sold to multiple brands, significantly lowering production and development expenses. Companies opting for white label solutions often face reduced marketing and design costs but sacrifice some control over product differentiation and customization.

Decision Factors: Which Model Suits Your Business?

Choosing between OEM and white label models depends on factors like control over product customization, brand identity, and cost structure. OEM suits businesses requiring tailored product development and exclusive branding, while white label is ideal for companies seeking quick market entry with minimal R&D investment. Evaluating scalability, intellectual property rights, and target market preferences helps determine the best fit for long-term growth.

Case Studies: Successful OEM and White Label Examples

Apple's collaboration with Foxconn exemplifies a successful OEM partnership, where Foxconn manufactures iPhones to Apple's specifications while maintaining Apple's brand identity. In contrast, Amazon's Echo devices showcase white-label strategy, sourcing products from third-party manufacturers rebranded under Amazon's name to rapidly expand its smart home ecosystem. These case studies highlight how OEM and white-label models optimize production efficiency and brand positioning in competitive markets.

OEM Infographic

libterm.com

libterm.com