Structural rigidity ensures that a building or object maintains its shape and withstands external forces without excessive deformation. This property is crucial in engineering and construction to guarantee safety, durability, and stability under various loads. Explore the rest of the article to understand how structural rigidity impacts your designs and projects.

Table of Comparison

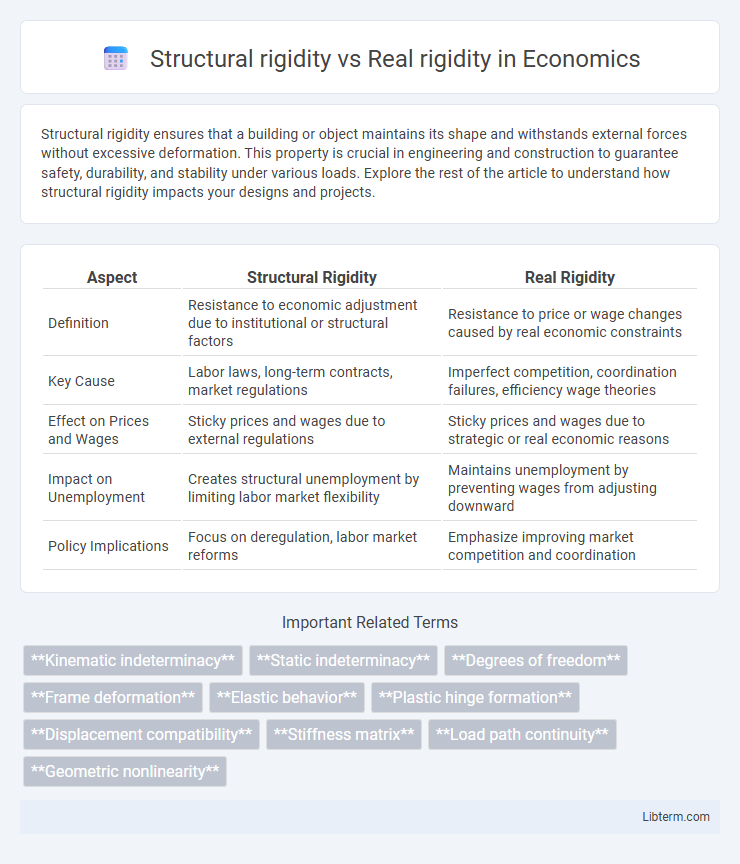

| Aspect | Structural Rigidity | Real Rigidity |

|---|---|---|

| Definition | Resistance to economic adjustment due to institutional or structural factors | Resistance to price or wage changes caused by real economic constraints |

| Key Cause | Labor laws, long-term contracts, market regulations | Imperfect competition, coordination failures, efficiency wage theories |

| Effect on Prices and Wages | Sticky prices and wages due to external regulations | Sticky prices and wages due to strategic or real economic reasons |

| Impact on Unemployment | Creates structural unemployment by limiting labor market flexibility | Maintains unemployment by preventing wages from adjusting downward |

| Policy Implications | Focus on deregulation, labor market reforms | Emphasize improving market competition and coordination |

Introduction to Structural Rigidity and Real Rigidity

Structural rigidity refers to the inherent ability of a framework or structure to maintain its shape and resist deformation under applied forces, largely defined by its geometric configuration and connectivity. Real rigidity extends this concept by incorporating material properties, such as elasticity and plasticity, to evaluate how actual physical components behave under stress, beyond idealized assumptions. Understanding both concepts is essential for accurate analysis and design of structures, ensuring stability and performance under real-world conditions.

Defining Structural Rigidity in Engineering and Physics

Structural rigidity in engineering and physics refers to a system's ability to maintain its shape and resist deformation under applied forces, characterized by the stiffness and connectivity of its components. Unlike real rigidity, which implies an idealized condition of absolute immovability, structural rigidity accounts for elastic deformations within a framework while preventing kinematic mechanisms. This concept is critical in designing stable structures, ensuring that the configuration of elements maintains equilibrium without significant strain or displacement.

Understanding Real Rigidity in Material Science

Real rigidity in material science refers to the actual resistance a material exhibits against deformation under applied stress, accounting for imperfections, defects, and environmental conditions. Unlike structural rigidity, which is an idealized measure based on geometry and material properties, real rigidity captures the true mechanical behavior observed in experimental settings. Understanding real rigidity is crucial for accurate predictions of material performance in real-world applications, ensuring safety and durability in engineering designs.

Key Differences Between Structural and Real Rigidity

Structural rigidity refers to the inherent stiffness of a material or structure based on its geometry and material properties, determining how much it deforms under applied loads. Real rigidity incorporates additional factors such as temperature effects, material imperfections, and dynamic loads, reflecting the actual behavior observed in practical applications. The key difference lies in structural rigidity being an idealized concept used for design calculations, while real rigidity accounts for environmental and operational conditions influencing true structural performance.

Factors Affecting Structural Rigidity

Structural rigidity depends on material properties such as Young's modulus and cross-sectional geometry, while real rigidity includes practical influences like boundary conditions and load distribution. Factors affecting structural rigidity include the type of material, shape and size of components, connection stiffness, and the presence of supports or restraints. Real rigidity also accounts for imperfections, joint flexibility, and dynamic loading effects that impact overall system stability.

Influences on Real Rigidity in Practical Applications

Real rigidity in practical applications is primarily influenced by factors such as material properties, connection types, and load distributions. Variations in temperature, manufacturing tolerances, and structural imperfections also significantly affect the actual stiffness of components. Understanding these influences helps engineers design structures that account for real-world deviations from idealized structural rigidity assumptions.

Structural Rigidity in Architectural Design

Structural rigidity in architectural design refers to a building's ability to maintain its shape and resist deformation under applied loads, ensuring stability and safety. This concept emphasizes the use of materials, geometric configuration, and connections that provide stiffness and limit deflections, which is critical for withstanding forces such as wind, earthquakes, and live loads. Unlike real rigidity, which assumes absolute immovability, structural rigidity acknowledges some flexibility but prioritizes adequate resistance to maintain overall integrity and functionality.

Real Rigidity and Its Role in Material Performance

Real rigidity refers to the inherent stiffness of a material, determined by its atomic bonding and microstructure, which directly influences its deformation behavior under load. Unlike structural rigidity that depends on geometry and size, real rigidity governs how materials resist shape changes at the molecular level, impacting their elasticity, strength, and durability. Understanding real rigidity is crucial for optimizing material performance in applications requiring precise mechanical stability and resilience against stress or fatigue.

Case Studies: Structural vs Real Rigidity in Practice

Case studies highlighting structural rigidity reveal organizations typically resistant to change due to entrenched policies, such as Kodak's delayed transition to digital photography, which hindered innovation and market adaptation. Real rigidity cases demonstrate the impact of fixed nominal prices on economic adjustments, exemplified by wage stickiness in Spain during the Eurozone crisis, where inflexible labor contracts prevented necessary wage reductions, exacerbating unemployment. Comparing these instances illustrates how structural rigidity stems from organizational frameworks, while real rigidity arises from economic constraints, both critically affecting adaptive capacity.

Conclusion: Balancing Structural and Real Rigidity for Optimal Design

Achieving optimal design requires a balance between structural rigidity, which ensures stability and load-bearing capacity, and real rigidity, reflecting material behavior under actual operating conditions. Overemphasizing structural rigidity can lead to excessive weight and cost, while neglecting real rigidity may result in premature failure due to unaccounted deformation. Integrating both concepts through advanced simulation techniques and material selection drives efficient, durable, and cost-effective engineering solutions.

Structural rigidity Infographic

libterm.com

libterm.com