Laterite is a soil type rich in iron and aluminum, commonly found in tropical regions with high rainfall. It forms through intense weathering and plays a crucial role in construction and agriculture due to its unique properties. Discover how laterite impacts your environment and why it matters by reading the rest of the article.

Table of Comparison

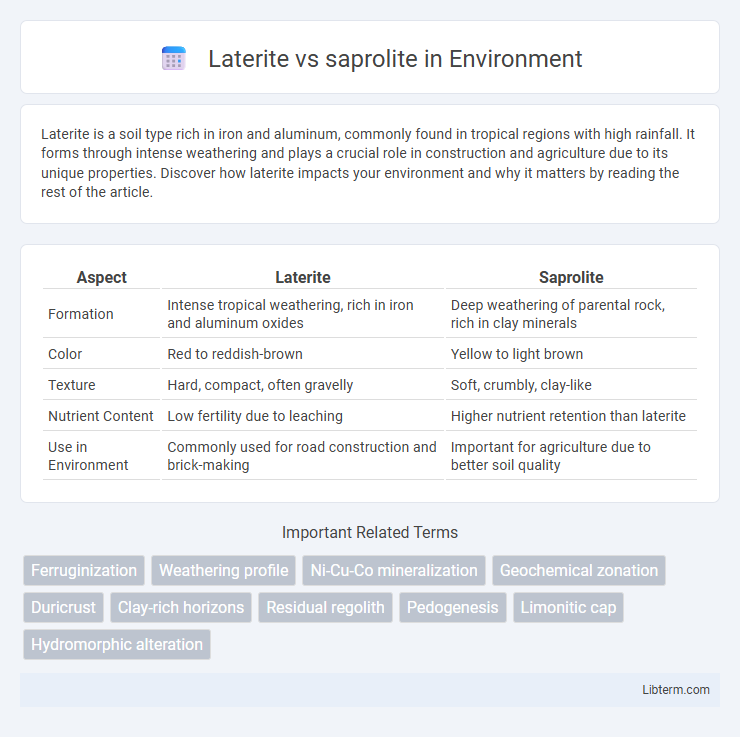

| Aspect | Laterite | Saprolite |

|---|---|---|

| Formation | Intense tropical weathering, rich in iron and aluminum oxides | Deep weathering of parental rock, rich in clay minerals |

| Color | Red to reddish-brown | Yellow to light brown |

| Texture | Hard, compact, often gravelly | Soft, crumbly, clay-like |

| Nutrient Content | Low fertility due to leaching | Higher nutrient retention than laterite |

| Use in Environment | Commonly used for road construction and brick-making | Important for agriculture due to better soil quality |

Introduction to Laterite and Saprolite

Laterite is a highly weathered soil rich in iron and aluminum oxides, commonly found in tropical regions with high rainfall and intense weathering processes. Saprolite is a softer, more clay-rich, and less weathered material that retains the original rock's texture and minerals, typically located beneath the laterite layer. Both laterite and saprolite serve as important indicators of tropical weathering intensity and are critical for understanding soil formation and mineral resource distribution.

Geological Formation Processes

Laterite forms through intense chemical weathering in tropical climates, where prolonged leaching removes silica and bases, enriching iron and aluminum oxides. Saprolite originates from the in-situ chemical weathering of bedrock, maintaining the rock's original texture while altering its mineralogy under moderate weathering conditions. The key difference lies in laterite's accumulation of insoluble minerals and saprolite's retention of parent rock features during geological formation.

Mineralogical Composition

Laterite primarily consists of iron and aluminum oxides such as hematite, goethite, and gibbsite, reflecting intense weathering and leaching processes in tropical climates. Saprolite retains more of the original bedrock minerals, including quartz, feldspar, and mica, with less alteration and lower concentrations of oxides compared to laterite. The mineralogical contrast between laterite and saprolite directly influences their chemical properties, soil fertility, and suitability for various industrial applications.

Physical Characteristics Comparison

Laterite exhibits a dense, hard texture with a reddish or rusty color due to iron oxide accumulation, while saprolite is softer, friable, and often pale or yellowish, reflecting less intense weathering. Laterite's compact structure results from leaching processes that concentrate iron and alumina, contrasting with saprolite's looser grain arrangement and higher clay mineral content. Porosity is typically lower in laterite, making it less permeable compared to the more porous and permeable saprolite layer beneath.

Occurrence and Global Distribution

Laterite soils predominantly occur in tropical and subtropical regions with high rainfall and intense weathering, such as parts of Africa, India, Southeast Asia, and South America. Saprolite is commonly found in humid temperate to tropical climates, often beneath laterite layers, with notable deposits in regions like the southeastern United States, Brazil, and Australia. Globally, laterite is widely distributed in latitudes between 10degN and 30degS where prolonged leaching occurs, while saprolite extends over broader climatic zones due to its formation from in-situ chemical weathering of parent rock.

Economic Importance and Uses

Laterite deposits are economically significant due to their high concentration of iron and aluminum oxides, making them essential sources for extracting metals like bauxite, nickel, and iron ore used in construction, manufacturing, and metallurgical industries. Saprolite, rich in weathered rock minerals, serves as a valuable ore for lateritic nickel mines, providing a crucial supply for stainless steel production and battery materials. Both laterite and saprolite contribute substantially to the mining sector, supporting economic growth through resource extraction and export revenues.

Laterite vs Saprolite in Nickel Ore Mining

Laterite and saprolite represent two distinct types of nickel ore deposits, each crucial in nickel mining due to their unique mineralogy and extraction methods. Laterite ores, formed through intense tropical weathering, are rich in iron and aluminum oxides with nickel concentrations usually between 1-2%, making them amenable to hydrometallurgical processing such as High Pressure Acid Leaching (HPAL). Saprolite ores originate from the in-situ weathering of ultramafic rocks and typically contain higher nickel grades (1.5-2.5%) with more magnesium silicates, favoring pyrometallurgical techniques like smelting for nickel recovery.

Environmental Impact of Extraction

Extraction of laterite often leads to significant soil erosion and deforestation, disrupting local ecosystems and reducing biodiversity. Saprolite mining causes lower surface degradation but can contaminate groundwater due to the leaching of minerals and chemicals. Both types of extraction require careful management to minimize adverse environmental impacts and maintain land stability.

Challenges in Processing and Extraction

Laterite presents challenges in processing due to its high iron and aluminum oxide content, resulting in dense, compact layers that require intensive mechanical processing and chemical treatment to extract valuable metals. Saprolite, being softer and less consolidated with higher nickel and cobalt content, allows for easier extraction but often requires careful handling to prevent contamination and loss of fine minerals during hydrometallurgical processes. Both ore types demand tailored beneficiation techniques to overcome mineralogical complexity and optimize recovery rates in nickel laterite mining.

Future Trends in Laterite and Saprolite Utilization

Future trends in laterite and saprolite utilization emphasize sustainable mining practices and advanced beneficiation technologies to enhance metal recovery, particularly for nickel and aluminum extraction. Integration of renewable energy in processing plants and development of eco-friendly leaching agents aim to reduce environmental impact while improving economic viability. Emerging research explores the potential of these materials as raw sources for battery metals, critical for electric vehicle and renewable energy storage industries.

Laterite Infographic

libterm.com

libterm.com