Decontamination involves the removal or neutralization of harmful substances from surfaces, equipment, or individuals to prevent contamination and ensure safety. Effective decontamination protocols are essential in healthcare, industrial settings, and emergency response to minimize health risks and environmental impact. Discover detailed methods and best practices on how your environment can be safely decontaminated in the rest of this article.

Table of Comparison

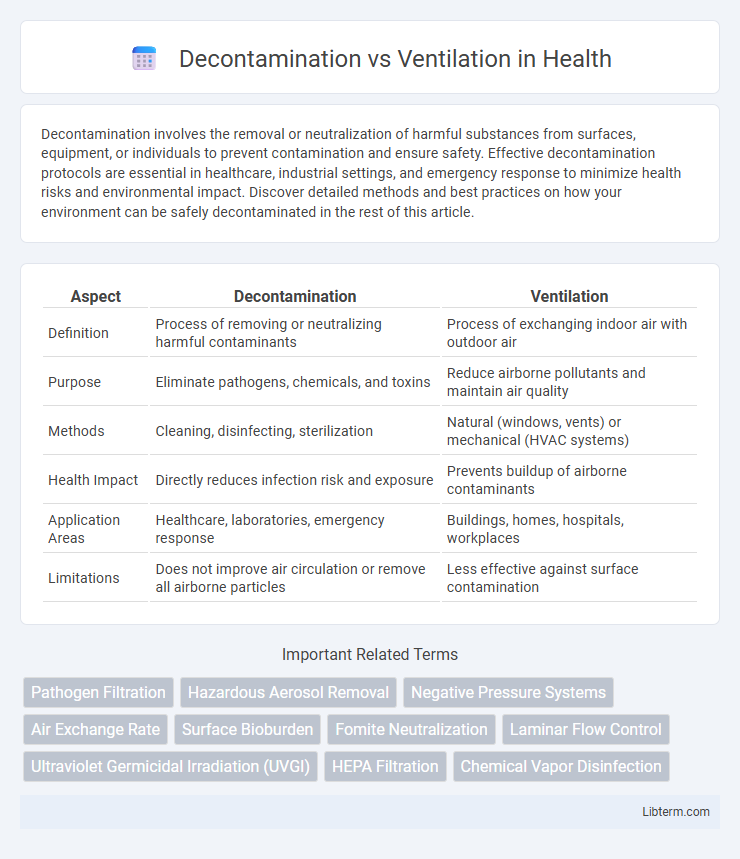

| Aspect | Decontamination | Ventilation |

|---|---|---|

| Definition | Process of removing or neutralizing harmful contaminants | Process of exchanging indoor air with outdoor air |

| Purpose | Eliminate pathogens, chemicals, and toxins | Reduce airborne pollutants and maintain air quality |

| Methods | Cleaning, disinfecting, sterilization | Natural (windows, vents) or mechanical (HVAC systems) |

| Health Impact | Directly reduces infection risk and exposure | Prevents buildup of airborne contaminants |

| Application Areas | Healthcare, laboratories, emergency response | Buildings, homes, hospitals, workplaces |

| Limitations | Does not improve air circulation or remove all airborne particles | Less effective against surface contamination |

Introduction: Understanding Decontamination and Ventilation

Decontamination involves the removal or neutralization of harmful substances from surfaces or environments, ensuring safety and preventing contamination spread. Ventilation refers to the process of exchanging indoor air with fresh outdoor air to reduce the concentration of airborne pollutants, including chemical, biological, and particulate contaminants. Both processes play critical roles in maintaining health and safety standards in industrial, healthcare, and environmental settings.

Defining Decontamination in Environmental Safety

Decontamination in environmental safety involves the systematic removal or neutralization of hazardous substances from surfaces, air, water, or soil to prevent exposure and contamination. This process includes methods such as chemical cleaning, physical removal, or bioremediation to restore environments to safe conditions. Effective decontamination reduces toxic risks and supports regulatory compliance, distinguishing it from ventilation, which primarily dilutes contaminants through air exchange.

The Science Behind Ventilation: Basics and Importance

Ventilation is the process of introducing fresh air into indoor spaces to dilute and remove contaminants, including airborne pathogens and volatile organic compounds. Its effectiveness depends on factors such as air exchange rate, airflow patterns, and filtration systems, which collectively reduce exposure to harmful substances. Proper ventilation is scientifically proven to lower the risk of respiratory infections and improve indoor air quality by maintaining optimal oxygen levels and minimizing pollutant concentrations.

Key Differences Between Decontamination and Ventilation

Decontamination involves the removal or neutralization of hazardous substances from people, equipment, or environments to prevent contamination spread, while ventilation focuses on the circulation and exchange of air to dilute and remove airborne contaminants. Decontamination requires specific agents and procedures tailored to the type of contaminant, whereas ventilation relies on mechanical or natural airflow methods to improve air quality. The key difference lies in decontamination addressing surface and body contamination, and ventilation targeting airborne hazards to maintain a safe environment.

When to Prioritize Decontamination Over Ventilation

Prioritize decontamination over ventilation when dealing with hazardous chemical spills, biological contaminants, or radiological exposure to prevent the spread of toxins and reduce direct health risks. Immediate decontamination is critical in environments where airborne contaminants are minimal but surface contamination can cause secondary exposure. In scenarios involving highly toxic or reactive substances, decontamination minimizes the overall contamination load before ventilation can safely disperse residual fumes.

Ventilation Strategies for Effective Hazard Control

Ventilation strategies play a crucial role in effective hazard control by reducing airborne contaminants and improving indoor air quality. Key methods include local exhaust ventilation (LEV) to capture pollutants at the source and dilution ventilation to introduce fresh air and disperse hazardous substances. Properly designed ventilation systems comply with OSHA guidelines and enhance worker safety by maintaining contaminant levels below permissible exposure limits (PELs).

Integrating Decontamination and Ventilation for Maximum Safety

Integrating decontamination and ventilation systems enhances maximum safety by simultaneously reducing airborne contaminants and surface pollutants. Effective ventilation dilutes hazardous particles in the air while decontamination processes eliminate pathogens and toxins from surfaces, creating a comprehensive contamination control strategy. Combining advanced filtration technologies with systematic cleaning protocols optimizes indoor air quality and minimizes health risks in high-exposure environments.

Common Misconceptions: Decontamination vs Ventilation

Decontamination and ventilation are often confused, but they serve distinct purposes in hazard control: decontamination removes contaminants from surfaces or individuals, while ventilation dilutes or removes airborne pollutants. A common misconception is that ventilation alone can eliminate surface contaminants, which is inaccurate as it primarily addresses air quality. Effective hazard management requires understanding that decontamination targets direct contaminant removal, whereas ventilation reduces airborne concentrations to improve breathing conditions.

Industry Applications: Case Studies and Best Practices

In industrial settings, decontamination processes such as chemical cleaning and thermal treatment effectively remove hazardous substances, ensuring worker safety and regulatory compliance. Ventilation systems employing advanced air exchange rates and filtration technologies play a critical role in controlling airborne contaminants, particularly in manufacturing plants and chemical processing facilities. Case studies reveal best practices including integrating real-time air quality monitoring with automated ventilation controls to optimize both decontamination efficiency and operational productivity.

Conclusion: Choosing the Right Approach for Risk Mitigation

Decontamination effectively eliminates hazardous contaminants from surfaces, reducing the potential for exposure, while ventilation dilutes airborne pollutants to improve indoor air quality. Selecting the appropriate risk mitigation strategy depends on the specific contamination type, exposure pathways, and environmental conditions present in the affected area. Integrating both decontamination and ventilation measures often provides a comprehensive approach to minimizing health risks in contaminated environments.

Decontamination Infographic

libterm.com

libterm.com