Resolving conflicts effectively requires clear communication and active listening to understand all parties' perspectives. Implementing practical solutions and seeking mutual agreements can prevent escalation and foster positive relationships. Discover more strategies to enhance your conflict resolution skills in the rest of this article.

Table of Comparison

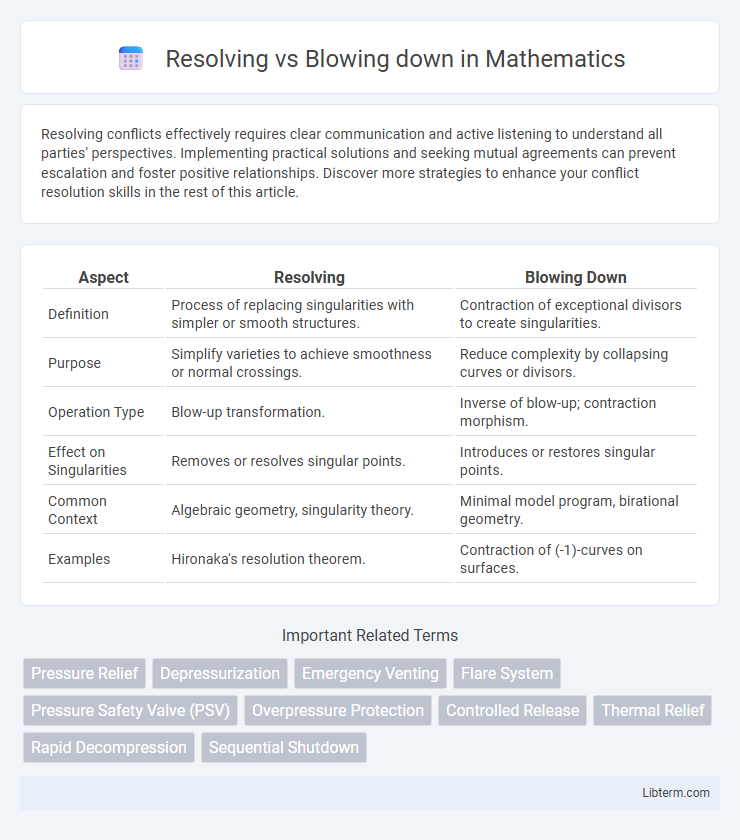

| Aspect | Resolving | Blowing Down |

|---|---|---|

| Definition | Process of replacing singularities with simpler or smooth structures. | Contraction of exceptional divisors to create singularities. |

| Purpose | Simplify varieties to achieve smoothness or normal crossings. | Reduce complexity by collapsing curves or divisors. |

| Operation Type | Blow-up transformation. | Inverse of blow-up; contraction morphism. |

| Effect on Singularities | Removes or resolves singular points. | Introduces or restores singular points. |

| Common Context | Algebraic geometry, singularity theory. | Minimal model program, birational geometry. |

| Examples | Hironaka's resolution theorem. | Contraction of (-1)-curves on surfaces. |

Understanding Resolving and Blowing Down

Resolving involves identifying and clarifying ambiguities or conflicts within data or systems to achieve accurate interpretation and functionality. Blowing down refers to the process of releasing excess pressure or waste materials, often in industrial contexts, to maintain safety and operational efficiency. Understanding resolving and blowing down is crucial for optimizing system performance and ensuring regulatory compliance in various technical fields.

Key Differences Between Resolving and Blowing Down

Resolving involves analyzing and breaking down data or problems into smaller components for clarity and decision-making, while blowing down refers to the deliberate process of reducing pressure or removing contaminants in engineering systems like boilers. The key difference lies in their domains: resolving pertains to cognitive or analytical tasks, whereas blowing down is a physical maintenance operation to ensure system safety and efficiency. Resolving aims at understanding and fixing issues through information processing, whereas blowing down focuses on physical control and operational stability.

Applications in Industrial Settings

Resolving in industrial settings involves precisely adjusting process variables to maintain optimal system performance, particularly in chemical manufacturing and power plants. Blowing down is a critical operation used to remove accumulated impurities or sediments from boilers and pressure vessels, ensuring safety and efficiency. Effective execution of both techniques enhances equipment lifespan and operational reliability in heavy industries.

Safety Considerations for Each Method

Resolving pressure issues by adjusting system parameters ensures controlled reduction, minimizing the risk of sudden pressure surges and equipment damage. Blowing down involves rapidly releasing pressure, which requires strict safety protocols to avoid hazards such as noise, debris ejection, and thermal shock to components. Proper training, use of protective equipment, and adherence to industry standards like ASME and OSHA guidelines are critical for safely managing both methods.

Environmental Impacts: Resolving vs. Blowing Down

Resolving processes typically minimize environmental impacts by recycling fluids and reducing waste discharge, whereas blowing down involves releasing large volumes of contaminated water or gases, contributing to air and water pollution. Resolving systems enhance sustainability through efficient resource management and lower emissions, while blowing down often results in higher energy consumption and increased environmental footprints. Implementing advanced resolving technologies supports regulatory compliance and promotes eco-friendly operations in industrial settings.

Efficiency and Cost Comparisons

Resolving steam traps involves cleaning or repairing, which extends equipment life and minimizes steam loss, enhancing overall system efficiency and reducing operating costs. Blowing down, while effective for removing accumulated debris and maintaining trap functionality, often results in higher steam wastage and increased fuel expenses due to frequent valve operations. Optimizing maintenance schedules by prioritizing resolving over blowing down can lead to significant energy savings and lower maintenance expenditures in steam systems.

Step-by-Step Process of Resolving

The step-by-step process of resolving typically involves identifying the root cause of an issue, gathering relevant data, analyzing possible solutions, and implementing corrective actions to address the problem effectively. This method emphasizes thorough evaluation and targeted intervention to prevent recurrence, contrasting with blowing down, which usually refers to quickly releasing pressure or clearing accumulated substances without detailed analysis. By following a systematic resolving process, organizations ensure long-term improvements and operational stability.

Step-by-Step Process of Blowing Down

Blowing down is a critical step in boiler maintenance involving the controlled removal of water to reduce impurities and sludge from the boiler system. The process begins by slowly opening the blowdown valve to allow water and sediment to escape, followed by closing the valve once the discharge appears clear, ensuring minimal heat and pressure loss. This step-by-step method helps maintain boiler efficiency, prevents corrosion, and complies with safety regulations by effectively managing water quality.

Common Challenges and Solutions

Resolving and blowing down processes often face challenges such as equipment fouling, pressure instability, and inefficient condensate removal, impacting operational efficiency and safety in pressure vessel and boiler management. Common solutions include implementing regular maintenance schedules, using automated control systems to monitor pressure and temperature fluctuations, and optimizing valve operation sequences to ensure smooth phase separation and condensate discharge. Employing advanced sensor technology and predictive analytics helps preempt failures and maintain consistent process conditions, thereby reducing downtime and enhancing system reliability.

Choosing the Right Method for Your Facility

Selecting the appropriate method between resolving and blowing down depends on the facility's operational requirements, safety protocols, and equipment specifications. Resolving improves efficiency by reducing pressure or concentration within a system through controlled processes, whereas blowing down rapidly relieves excess pressure or removes impurities to maintain system integrity. Evaluating factors such as system design, maintenance schedules, and environmental regulations ensures optimal performance and compliance when choosing between these two techniques.

Resolving Infographic

libterm.com

libterm.com