Isotropic materials exhibit uniform properties in all directions, making them essential in fields like physics and engineering for consistent performance. Understanding isotropy helps in designing components that behave predictably under various stresses and conditions. Explore the rest of the article to discover how isotropic properties impact your projects and applications.

Table of Comparison

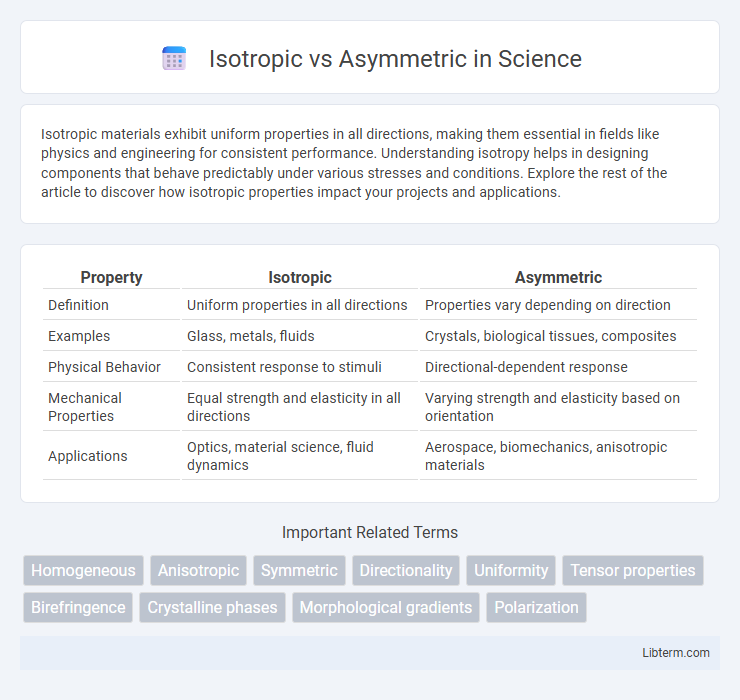

| Property | Isotropic | Asymmetric |

|---|---|---|

| Definition | Uniform properties in all directions | Properties vary depending on direction |

| Examples | Glass, metals, fluids | Crystals, biological tissues, composites |

| Physical Behavior | Consistent response to stimuli | Directional-dependent response |

| Mechanical Properties | Equal strength and elasticity in all directions | Varying strength and elasticity based on orientation |

| Applications | Optics, material science, fluid dynamics | Aerospace, biomechanics, anisotropic materials |

Understanding Isotropic and Asymmetric Materials

Isotropic materials exhibit uniform properties in all directions, making them predictable and consistent under various loading conditions. Asymmetric materials have directional dependence, meaning their mechanical, thermal, or optical properties vary based on orientation. Understanding the difference between isotropic and asymmetric materials is crucial for applications in engineering, materials science, and design where directional behavior impacts performance and durability.

Key Differences Between Isotropic and Asymmetric Properties

Isotropic materials exhibit uniform properties in all directions, making them ideal for applications requiring consistent performance, such as metals and glass. Asymmetric materials, however, have direction-dependent properties, often found in composites and crystals, which influence their mechanical strength and optical behavior. Understanding these differences is crucial for selecting materials in engineering, where isotropic materials provide predictability, and asymmetric materials enable tailored functionalities.

Applications of Isotropic Materials in Industry

Isotropic materials exhibit uniform properties in all directions, making them ideal for applications requiring consistent performance, such as metal components in aerospace and automotive industries. Their predictable mechanical behavior enhances reliability in structural parts, ensuring safety and efficiency in manufacturing. Industries utilize isotropic materials for precision instruments, pressure vessels, and machine parts where directional independence in strength and durability is critical.

Advantages of Asymmetric Materials

Asymmetric materials offer enhanced directional properties that improve performance in applications requiring tailored mechanical, thermal, or electrical behaviors. Their anisotropic nature allows engineers to optimize strength, stiffness, and conductivity along specific axes, surpassing the uniform characteristics of isotropic materials. This directional control facilitates lightweight structures and energy-efficient systems in aerospace, automotive, and electronics industries.

Mechanical Behavior: Isotropic vs Asymmetric

Isotropic materials exhibit uniform mechanical behavior in all directions, meaning their strength, elasticity, and deformation response remain consistent regardless of the load orientation. Asymmetric materials display direction-dependent mechanical properties, leading to varying stiffness, strength, and failure mechanisms when subjected to different stress directions. Understanding these distinctions is critical for designing components subjected to complex loading conditions, ensuring reliability and optimal performance.

Impact on Product Design and Engineering

Isotropic materials exhibit uniform properties in all directions, simplifying product design by ensuring consistent performance under varied stress orientations, which reduces the complexity of engineering simulations and testing. Asymmetric materials possess direction-dependent characteristics, requiring engineers to tailor design approaches to optimize strength, durability, and functionality according to specific load paths and operational conditions. Understanding the impact of isotropic versus asymmetric behavior enables precise material selection and structural optimization, enhancing overall product reliability and performance in sectors like aerospace, automotive, and electronics.

Testing Methods for Isotropic and Asymmetric Properties

Testing methods for isotropic properties typically involve uniform measurements in multiple directions using techniques like tensile testing, ultrasonic pulse velocity, or hardness testing to confirm consistent material behavior irrespective of orientation. In contrast, testing asymmetric properties requires direction-dependent evaluations such as anisotropic tensile testing, shear testing at different angles, or ultrasonic testing with varying wave propagation directions to capture variations in mechanical or acoustic responses. Advanced methods like X-ray diffraction and electron backscatter diffraction (EBSD) can further analyze crystallographic texture and grain orientation, crucial for accurately characterizing asymmetric materials.

Material Selection Criteria: Isotropic or Asymmetric?

Material selection criteria hinge on understanding isotropic versus asymmetric properties, where isotropic materials exhibit uniform strength and thermal expansion in all directions, ideal for applications requiring consistent performance under multi-directional stresses. Asymmetric materials, often composite laminates or single-crystal structures, provide tailored mechanical properties and enhanced strength along specific axes, benefiting aerospace and automotive components subjected to directional loads. Evaluating the operational environment, load conditions, and performance requirements determines whether isotropic homogeneity or asymmetric anisotropy optimizes material efficiency and durability.

Case Studies: Real-World Examples

Case studies in seismic imaging reveal isotropic models often simplify subsurface interpretations, providing uniform velocity assumptions that suit sedimentary basins but miss complex geologies. Asymmetric models, incorporating anisotropy and heterogeneity, enhance accuracy in areas like fractured reservoirs and fold-thrust belts by capturing directional velocity variations. Real-world examples from Gulf of Mexico and North Sea demonstrate improved hydrocarbon detection and reservoir characterization using asymmetric seismic modeling.

Future Trends in Material Science: Isotropic vs Asymmetric

Future trends in material science emphasize the development of asymmetric materials due to their unique directional properties that enable enhanced performance in applications like flexible electronics and advanced composites. Isotropic materials continue to be relevant for uniform stress distribution in structural components, but asymmetric designs are increasingly favored for tailored functionalities at the nanoscale. Innovations in additive manufacturing and nanotechnology drive the precise control of asymmetry, opening pathways for smart materials with customizable mechanical, thermal, and optical characteristics.

Isotropic Infographic

libterm.com

libterm.com