Radial designs optimize space by extending elements outward from a central point, creating balanced and visually appealing layouts. This structure enhances user engagement by naturally guiding the eye along each spoke or segment. Discover how radial patterns can transform your projects and improve functionality in the full article.

Table of Comparison

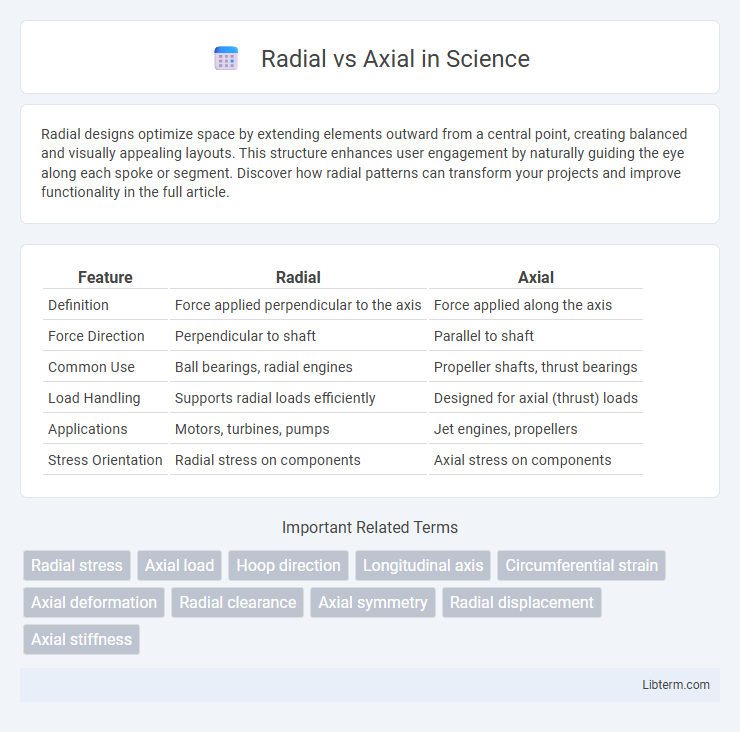

| Feature | Radial | Axial |

|---|---|---|

| Definition | Force applied perpendicular to the axis | Force applied along the axis |

| Force Direction | Perpendicular to shaft | Parallel to shaft |

| Common Use | Ball bearings, radial engines | Propeller shafts, thrust bearings |

| Load Handling | Supports radial loads efficiently | Designed for axial (thrust) loads |

| Applications | Motors, turbines, pumps | Jet engines, propellers |

| Stress Orientation | Radial stress on components | Axial stress on components |

Introduction to Radial and Axial Concepts

Radial and axial describe two fundamental orientations in mechanical and electrical engineering, representing directions relative to an object's axis. Radial refers to a direction moving outward from the center or shaft, critical in bearings and fan blade designs where forces radiate perpendicular to the axis. Axial indicates movement or force along the axis or length of a component, essential in applications like axial flow compressors and shaft-driven systems that operate parallel to the axis.

Definition of Radial vs Axial

Radial and axial refer to directions relative to an object's geometry: radial direction extends outward from the center or axis, while axial direction runs parallel to the object's central axis or length. In mechanical contexts, radial forces act perpendicular to the shaft, influencing bearing load, whereas axial forces apply along the shaft's length, affecting thrust load. Understanding the distinction between radial and axial directions is critical for designing components such as bearings, motors, and turbines to ensure proper load management and durability.

Key Differences Between Radial and Axial

Radial and axial lead styles differ primarily in their orientations and applications; radial leads extend perpendicularly from the component body, while axial leads protrude from both ends along the component's axis. Radial components typically offer a more compact footprint ideal for automated assembly in high-density circuit boards, whereas axial components provide easier alignment and flexibility in connecting wires or through-hole mounting. Electrical characteristics remain similar, but the mechanical and layout advantages influence their selection in electronic design.

Radial Applications Across Industries

Radial components, known for their robust construction and superior heat dissipation, are extensively utilized in automotive, aerospace, and industrial machinery sectors for applications requiring high reliability and performance under dynamic conditions. Their design enables efficient handling of radial loads, making them ideal for electric motors, gearboxes, and heavy-duty pumps in manufacturing plants and transportation equipment. Industries leverage radial bearings and capacitors to enhance equipment durability and operational efficiency, underscoring their critical role in modern engineering solutions.

Axial Applications Across Industries

Axial capacitors are widely utilized in automotive electronics for ignition systems and headlight circuits due to their reliable voltage handling and compact form factor. In consumer electronics, axial capacitors are favored for their ease of installation on printed circuit boards, especially in audio equipment and power supplies. Industrial machinery also relies on axial capacitors for motor start and run applications, benefiting from their high ripple current capacity and durability under mechanical stress.

Radial vs Axial in Mechanical Engineering

In mechanical engineering, radial and axial refer to two primary directions of force or motion relative to a rotating shaft. Radial forces act perpendicular to the shaft axis and are commonly addressed in the design of radial ball bearings, which support loads from the side, while axial forces act parallel to the shaft and are managed by thrust bearings designed to handle push or pull forces along the shaft. Selecting appropriate bearings to accommodate radial or axial loads is critical for ensuring efficiency, reducing wear, and prolonging the lifespan of rotating machinery components.

Pros and Cons of Radial Orientation

Radial orientation in electrical machines offers improved thermal management due to better cooling efficiency and reduced hot spots, enhancing overall performance and longevity. However, radial designs typically have a more complex manufacturing process and increased material costs compared to axial counterparts. The radial layout also allows for higher torque density but may result in larger machine size and weight, impacting applications where compactness is critical.

Pros and Cons of Axial Orientation

Axial capacitors offer lower equivalent series resistance (ESR) and inductance compared to radial capacitors, enhancing performance in high-frequency applications. Their streamlined design allows easier mounting on narrow circuit boards but can complicate automated assembly processes due to lead spacing. However, axial orientation provides superior mechanical stability in vibrational environments, while radial types generally support higher capacitance in a more compact footprint.

How to Choose Between Radial and Axial

Choosing between radial and axial components depends on the application's space constraints, electrical characteristics, and mechanical requirements. Radial components, with leads exiting parallel to the component body, are ideal for compact, vertical mounting and efficient PCB space usage. Axial components, featuring leads extending from both ends along the component's axis, suit applications needing more robust mechanical stability and easy manual assembly.

Future Trends in Radial and Axial Technologies

Radial and axial technologies are evolving with advancements in materials science and manufacturing precision, driving improvements in efficiency and performance for electric motors and generators. Future trends highlight the integration of smart sensors and IoT connectivity in both radial and axial designs, enabling predictive maintenance and enhanced operational control. Innovations in lightweight composites and additive manufacturing are expected to reduce weight and production costs, accelerating the adoption of axial flux motors in electrification and renewable energy sectors.

Radial Infographic

libterm.com

libterm.com