Chillers are essential components in cooling systems, efficiently removing heat from liquids to maintain optimal temperatures in various industrial and commercial applications. They improve energy efficiency and ensure reliable operation of HVAC systems by regulating the temperature of equipment and processes. Discover how choosing the right chiller can enhance your system's performance and reduce operating costs in the full article.

Table of Comparison

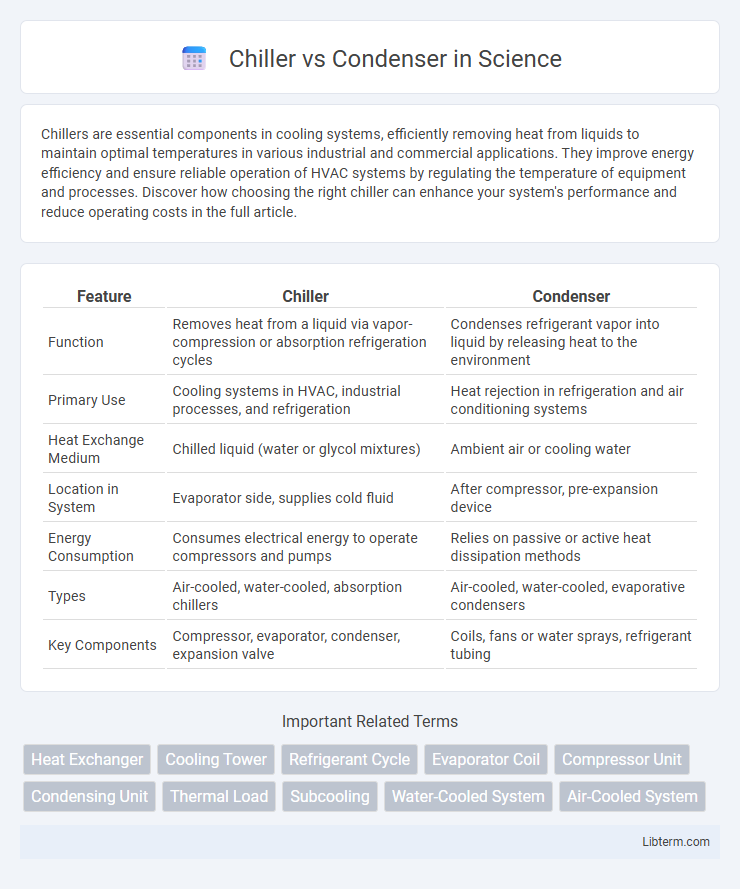

| Feature | Chiller | Condenser |

|---|---|---|

| Function | Removes heat from a liquid via vapor-compression or absorption refrigeration cycles | Condenses refrigerant vapor into liquid by releasing heat to the environment |

| Primary Use | Cooling systems in HVAC, industrial processes, and refrigeration | Heat rejection in refrigeration and air conditioning systems |

| Heat Exchange Medium | Chilled liquid (water or glycol mixtures) | Ambient air or cooling water |

| Location in System | Evaporator side, supplies cold fluid | After compressor, pre-expansion device |

| Energy Consumption | Consumes electrical energy to operate compressors and pumps | Relies on passive or active heat dissipation methods |

| Types | Air-cooled, water-cooled, absorption chillers | Air-cooled, water-cooled, evaporative condensers |

| Key Components | Compressor, evaporator, condenser, expansion valve | Coils, fans or water sprays, refrigerant tubing |

Introduction: Understanding Chillers and Condensers

Chillers are refrigeration systems designed to remove heat from a liquid via a vapor-compression or absorption refrigeration cycle, primarily used in industrial and commercial cooling applications. Condensers function by converting refrigerant vapor into liquid through heat exchange, typically using air or water to dissipate heat from the system. Understanding the distinct roles of chillers and condensers is essential for optimizing HVAC and process cooling efficiency.

What is a Chiller?

A chiller is an advanced HVAC system component designed to remove heat from a liquid via a vapor-compression or absorption refrigeration cycle, effectively cooling spaces or industrial processes. Chillers play a critical role in providing precise temperature control by circulating chilled water or coolant to air handlers, cooling towers, or manufacturing equipment. The efficiency and capacity of chillers are measured by their cooling tons and coefficient of performance (COP), distinguishing them from condensers, which primarily function as heat exchangers in refrigeration cycles.

What is a Condenser?

A condenser is a critical component in HVAC and refrigeration systems responsible for converting refrigerant vapor into liquid by dissipating heat to the surrounding environment. It typically consists of coils and fins that facilitate heat exchange, using air or water as a cooling medium. This process allows the refrigerant to continue its cycle efficiently, supporting temperature regulation and system performance.

Key Differences Between Chillers and Condensers

Chillers and condensers serve distinct roles in HVAC and refrigeration systems, with chillers primarily responsible for removing heat from a liquid via a vapor-compression or absorption cycle, while condensers expel heat from refrigerant vapor, turning it into liquid. Chillers circulate chilled water or coolant to cool air or equipment, whereas condensers release the absorbed heat to the external environment, typically through air or water-cooled coils. Key differences include their placement in the cooling cycle and their function; chillers provide cooled fluid for cooling applications, and condensers facilitate heat rejection from refrigerants.

Working Principles of Chillers

Chillers operate by extracting heat from a liquid through a refrigeration cycle, which involves the compression, condensation, expansion, and evaporation of a refrigerant to absorb and remove heat from the chilled water system. The compressor increases the pressure and temperature of the refrigerant vapor before it moves to the condenser, where heat is expelled to the environment, often through air or water cooling. This cooled refrigerant then expands and evaporates, absorbing heat from the water circulating through the chiller, effectively cooling the water for use in air conditioning or industrial processes.

Working Principles of Condensers

Condensers operate by transferring heat from the hot refrigerant vapor to a cooling medium, typically air or water, causing the vapor to condense into a high-pressure liquid. This phase change releases latent heat, which the condenser dissipates to the surroundings, maintaining the refrigeration cycle's efficiency. Unlike chillers that cool fluids via vapor-compression or absorption, condensers specifically manage heat rejection crucial for system performance.

Applications of Chillers in Industry

Chillers are extensively used in industries like manufacturing, chemical processing, and pharmaceuticals to control equipment temperature and ensure process stability. These systems provide precise cooling for machinery, mold cooling, and temperature regulation in large-scale HVAC systems. Condensers, while essential in refrigeration cycles, mainly function to dissipate heat, making chillers more critical for direct cooling applications in industrial environments.

Common Uses for Condensers

Condensers are commonly used in HVAC systems to expel heat from refrigerants, facilitating the cooling process in air conditioners and refrigeration units. Industrial applications utilize condensers in power plants and chemical processing to convert steam or gases back into liquids, improving system efficiency. These devices play a critical role in automotive cooling systems by dissipating engine heat, thereby preventing overheating and maintaining optimal engine performance.

Energy Efficiency: Chiller vs Condenser

Chillers and condensers play crucial roles in HVAC systems, with energy efficiency varying based on their type and application. Chillers, particularly those with variable-speed compressors, often deliver higher energy efficiency by precisely controlling cooling loads and reducing power consumption during partial loads. Condensers, integral to heat rejection, impact overall system efficiency through their design, such as air-cooled vs. water-cooled configurations, with water-cooled condensers typically providing better energy performance in large-scale cooling systems.

Choosing the Right System for Your Needs

Choosing the right system between a chiller and a condenser depends on the specific cooling requirements and application context. Chillers are ideal for providing precise temperature control in large-scale industrial processes or HVAC systems, while condensers are primarily used to expel heat from refrigerants in air conditioning units or refrigeration cycles. Evaluating factors such as cooling capacity, energy efficiency, installation space, and maintenance costs will help determine the optimal solution for your cooling needs.

Chiller Infographic

libterm.com

libterm.com