A reboiler is a critical heat exchanger used in industrial processes to provide the necessary heat to the bottom of distillation columns, enabling the separation of chemical components through vaporization. Efficient reboiler operation ensures optimal energy use and maintains process stability by controlling temperature and flow rates. Discover how your system can benefit from advanced reboiler designs and maintenance strategies by reading the rest of the article.

Table of Comparison

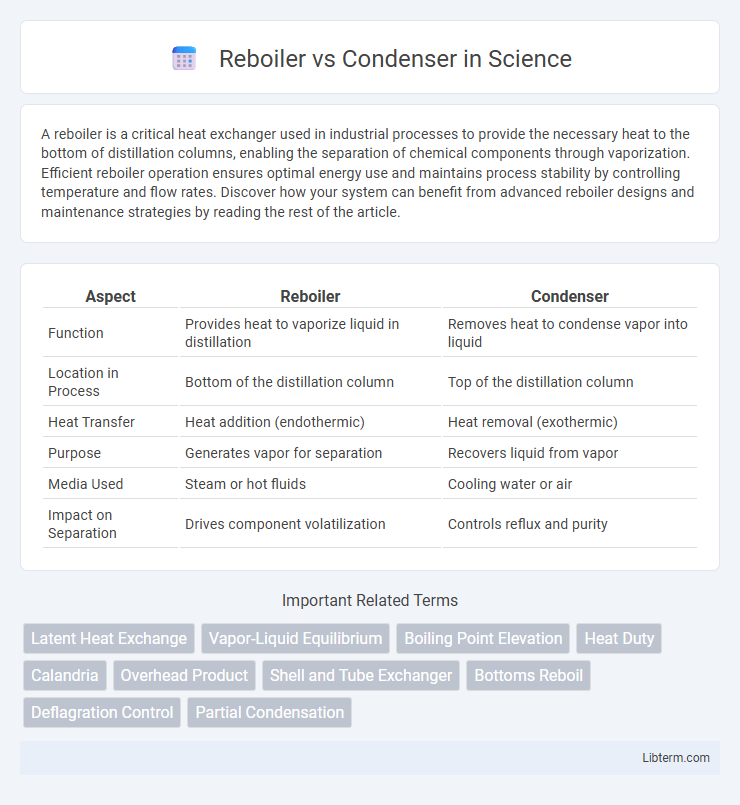

| Aspect | Reboiler | Condenser |

|---|---|---|

| Function | Provides heat to vaporize liquid in distillation | Removes heat to condense vapor into liquid |

| Location in Process | Bottom of the distillation column | Top of the distillation column |

| Heat Transfer | Heat addition (endothermic) | Heat removal (exothermic) |

| Purpose | Generates vapor for separation | Recovers liquid from vapor |

| Media Used | Steam or hot fluids | Cooling water or air |

| Impact on Separation | Drives component volatilization | Controls reflux and purity |

Introduction to Reboilers and Condensers

Reboilers and condensers are essential heat exchangers in distillation processes, where reboilers provide the necessary heat to generate vapor at the bottom of the column, enhancing separation efficiency. Condensers, positioned at the top of the column, cool and condense vapor back into liquid, allowing for reflux and product collection. Understanding their distinct roles and operational parameters is critical for optimizing heat integration and energy consumption in chemical processing units.

Basic Functions and Principles

A reboiler supplies heat to the bottom of a distillation column, generating vapor to drive the separation process by boiling the liquid feed. A condenser removes heat from the vapor at the top of the column, condensing it back into liquid to either collect as a product or return as reflux. Both devices operate on heat exchange principles, with reboilers providing latent heat for vaporization and condensers facilitating heat rejection for condensation.

Key Differences Between Reboilers and Condensers

Reboilers supply heat to the bottom of distillation columns to vaporize liquid mixtures, whereas condensers remove heat at the top to convert vapor back into liquid. Reboilers operate by transferring thermal energy to generate vapor, while condensers rely on cooling mechanisms, often using water or air, to condense vapor into liquid. These equipment differences directly impact the energy balance and operational control within chemical separation processes.

Types of Reboilers

Reboilers, essential for providing the heat required for the distillation process, come in several types: kettle, thermosiphon, and forced circulation. Kettle reboilers use a shell-and-tube design with liquid levels controlling heat transfer, while thermosiphon reboilers rely on natural circulation driven by density differences. Forced circulation reboilers utilize pumps to circulate the liquid, offering higher heat transfer rates and prevention of fouling in high-viscosity fluids.

Types of Condensers

Types of condensers include air-cooled, shell-and-tube, and plate condensers, each designed to efficiently remove heat by condensing vapor into liquid using air or cooling water. Air-cooled condensers use ambient air as a cooling medium, suitable for environments lacking water resources, while shell-and-tube condensers rely on water or other fluids flowing through tubes surrounded by vapor for heat exchange. Plate condensers consist of thin, corrugated plates to maximize surface area for heat transfer, making them ideal for compact installations with high thermal performance requirements.

Design Considerations for Reboilers and Condensers

Design considerations for reboilers involve ensuring efficient heat transfer while maintaining proper fluid circulation to avoid overheating or fouling, with common types including kettle, thermosyphon, and forced circulation designs. Condenser design focuses on maximizing condensate removal and heat exchange efficiency, often selecting between air-cooled or water-cooled systems based on cooling medium availability and process requirements. Material selection, pressure drop constraints, and maintenance accessibility are critical factors influencing both reboiler and condenser design to optimize performance and longevity.

Applications in Industrial Processes

Reboilers are primarily used in distillation columns to provide the necessary heat for vaporizing the liquid mixture, essential in refining, petrochemical processing, and chemical manufacturing. Condensers serve to cool and condense vapor back into liquid form, playing a critical role in processes such as vapor recovery units, refrigeration cycles, and solvent recovery systems. Both units optimize mass and heat transfer efficiency, directly impacting energy consumption and product purity in large-scale industrial operations.

Efficiency and Performance Factors

Reboilers and condensers are critical components in distillation columns, with reboiler efficiency dependent on heat transfer rates and steam utilization, while condenser performance hinges on effective cooling medium flow and temperature control. Performance factors for reboilers include fouling resistance and thermal conductivity of heat exchange surfaces, whereas condensers require minimal pressure drop and optimal condensing area to maintain phase change efficiency. Maximizing energy recovery in reboilers and ensuring consistent subcooling in condensers are essential for improving overall process energy efficiency and separation quality.

Maintenance and Troubleshooting

Reboilers require regular inspection for scaling and tube fouling to maintain efficient heat transfer, with common issues including leaks and overheating that can reduce performance. Condensers demand frequent cleaning to prevent fouling and corrosion in cooling water channels, and troubleshooting often involves checking for air leaks and ensuring proper coolant flow to avoid inefficient condensation. Both units benefit from routine monitoring of temperature and pressure parameters to detect anomalies early and minimize downtime.

Selection Criteria: Choosing Reboilers or Condensers

Selection criteria for choosing reboilers or condensers depend on process requirements such as temperature, pressure, and heat duty. Reboilers are selected for providing the necessary vaporization in distillation columns, emphasizing high heat transfer efficiency and minimal liquid hold-up. Condensers are chosen for condensing vapors with considerations including cooling medium availability, condensation temperature, and pressure drop constraints.

Reboiler Infographic

libterm.com

libterm.com