Directional products optimize the flow and efficiency of your processes by guiding movement precisely where needed. Understanding the benefits and applications of directional technology can enhance operational accuracy and reduce waste. Explore the full article to discover how directional solutions can transform your workflow.

Table of Comparison

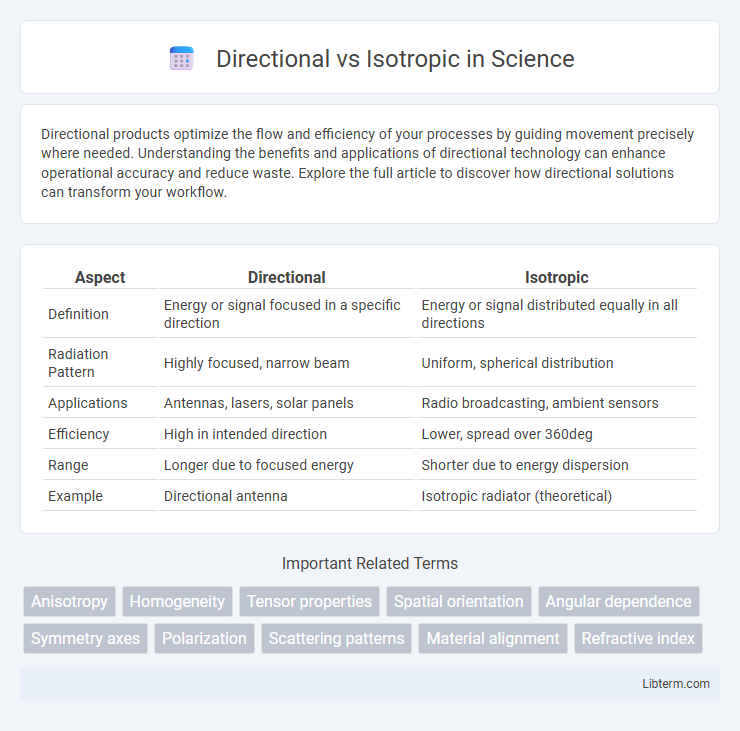

| Aspect | Directional | Isotropic |

|---|---|---|

| Definition | Energy or signal focused in a specific direction | Energy or signal distributed equally in all directions |

| Radiation Pattern | Highly focused, narrow beam | Uniform, spherical distribution |

| Applications | Antennas, lasers, solar panels | Radio broadcasting, ambient sensors |

| Efficiency | High in intended direction | Lower, spread over 360deg |

| Range | Longer due to focused energy | Shorter due to energy dispersion |

| Example | Directional antenna | Isotropic radiator (theoretical) |

Understanding Directional and Isotropic Concepts

Directional concepts refer to properties or measurements that vary based on a specific orientation or angle, such as directional microphones capturing sound predominantly from one direction. Isotropic concepts describe uniformity in all directions, meaning characteristics remain constant regardless of the angle, exemplified by isotropic antennas radiating signal strength equally in every direction. Understanding these differences is crucial in fields like physics, acoustics, and antenna design, where choosing between directional and isotropic models impacts performance and accuracy.

Key Differences Between Directional and Isotropic Properties

Directional properties vary based on orientation, meaning their values change depending on the direction of measurement, which is crucial in materials like composites and crystals that exhibit anisotropy. Isotropic properties remain constant regardless of direction, providing uniform behavior in all orientations, commonly seen in materials such as metals and glass. Understanding these key differences aids in selecting appropriate materials for engineering applications requiring specific mechanical, thermal, or optical performance.

Real-World Examples of Directional Materials

Directional materials are characterized by properties that vary depending on the direction of measurement, commonly seen in wood, which exhibits higher strength along the grain than across it. Composite materials like carbon fiber reinforced polymers also demonstrate directional strength, making them ideal for aerospace and automotive applications where load paths are predictable. In contrast, isotropic materials such as metals typically have uniform properties in all directions, simplifying design considerations.

Isotropic Materials: Common Applications

Isotropic materials exhibit uniform properties in all directions, making them ideal for applications requiring consistent strength and conductivity. Common uses include metals like aluminum and copper in electrical wiring, glass in optical lenses, and polymers in packaging due to their predictable mechanical behavior. Their homogeneity simplifies design processes in aerospace, automotive, and civil engineering sectors where isotropic stress distribution is critical.

How Directional Properties Affect Performance

Directional properties significantly influence sensor and antenna performance by enhancing sensitivity and accuracy in targeted areas while minimizing interference from unwanted directions. Devices with directional characteristics concentrate energy or reception in a specific path, leading to improved signal strength and reduced noise compared to isotropic counterparts that distribute energy uniformly. This focused approach boosts overall efficiency in applications like radar, wireless communication, and imaging systems.

Measuring Isotropy and Directionality

Measuring isotropy involves assessing uniformity in all directions, often quantified using parameters such as the isotropy index derived from tensor-based metrics like diffusion tensor imaging (DTI). Directionality measurement evaluates the degree to which physical properties or patterns align preferentially along specific axes, using tools like directional variance or anisotropy coefficients. Techniques such as spherical harmonics decomposition help distinguish isotropic diffusion from directional diffusion, enabling accurate characterization of material or signal properties.

Advantages of Directional Materials

Directional materials exhibit superior strength and stiffness along specific orientations, making them ideal for applications requiring high performance under targeted loads. Their anisotropic nature allows for optimized weight-to-strength ratios, enhancing structural efficiency in aerospace and automotive industries. Enhanced fatigue resistance and tailored thermal expansion properties further contribute to their widespread use in advanced engineering solutions.

Benefits of Isotropic Materials

Isotropic materials offer uniform properties in all directions, enhancing consistency and reliability in applications like aerospace and electronics where predictable performance under varying stresses is crucial. Their homogeneous structure improves fatigue resistance and reduces the risk of structural failures compared to directional materials, which may have weak points along certain axes. This uniformity simplifies design processes and increases efficiency in manufacturing, leading to cost savings and improved product longevity.

Choosing Between Directional and Isotropic Materials

Choosing between directional and isotropic materials depends on the specific application requirements such as mechanical strength, thermal conductivity, and electrical properties. Directional materials exhibit anisotropic behavior, offering superior performance along a particular axis, ideal for aerospace components and high-performance composites. Isotropic materials provide uniform properties in all directions, making them suitable for general structural applications and ensuring consistent performance regardless of orientation.

Future Trends in Material Science: Directional vs Isotropic

Future trends in material science emphasize the development of directional materials with tailored anisotropic properties to enhance mechanical strength, thermal conductivity, and electronic performance in applications such as flexible electronics and aerospace components. Advanced manufacturing techniques like additive manufacturing and nanoscale patterning enable precise control over microstructural orientation, optimizing isotropic materials for uniform performance in multi-directional stress environments. Integration of machine learning models accelerates the discovery and design of hybrid materials combining directional and isotropic features for next-generation high-performance, sustainable materials.

Directional Infographic

libterm.com

libterm.com