Fair compensation is essential for maintaining employee motivation and ensuring long-term organizational success by aligning pay with performance and market standards. Transparent and competitive compensation structures help attract and retain top talent while fostering a positive workplace culture. Explore the rest of the article to discover key strategies for optimizing Your compensation approach effectively.

Table of Comparison

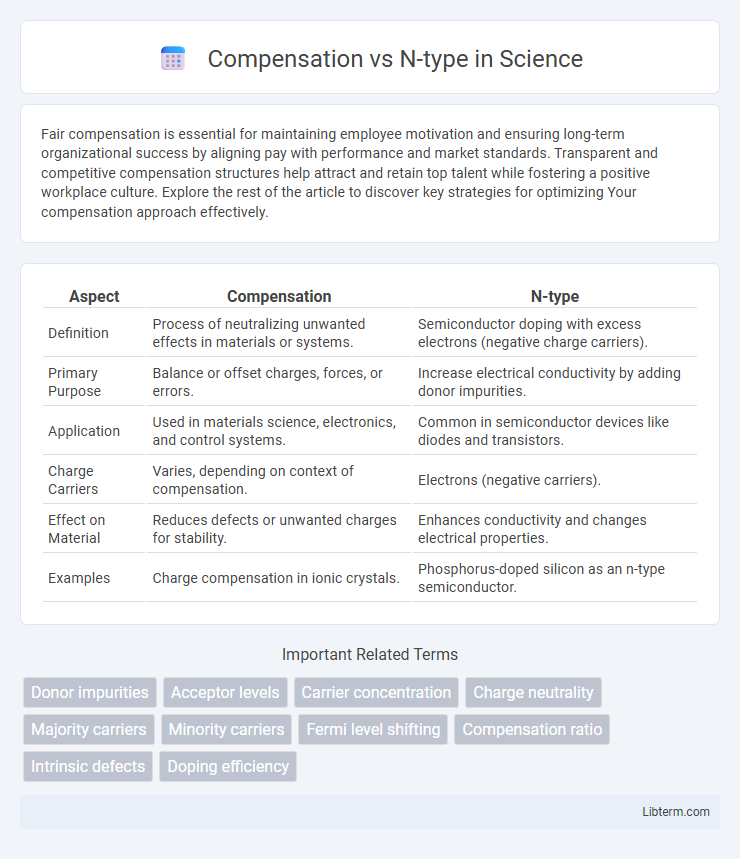

| Aspect | Compensation | N-type |

|---|---|---|

| Definition | Process of neutralizing unwanted effects in materials or systems. | Semiconductor doping with excess electrons (negative charge carriers). |

| Primary Purpose | Balance or offset charges, forces, or errors. | Increase electrical conductivity by adding donor impurities. |

| Application | Used in materials science, electronics, and control systems. | Common in semiconductor devices like diodes and transistors. |

| Charge Carriers | Varies, depending on context of compensation. | Electrons (negative carriers). |

| Effect on Material | Reduces defects or unwanted charges for stability. | Enhances conductivity and changes electrical properties. |

| Examples | Charge compensation in ionic crystals. | Phosphorus-doped silicon as an n-type semiconductor. |

Introduction to Compensation and N-type Concepts

Compensation techniques enhance the performance and stability of electronic circuits by adjusting gain and frequency response, critical in amplifier and feedback systems. N-type concepts refer to a classification of semiconductor materials or transistor types with negative charge carriers (electrons) as the majority carriers, influencing device behavior and application. Understanding the interplay between compensation methods and N-type components is essential for optimizing electronic circuit functionality and reliability.

Defining Compensation in Semiconductor Physics

Compensation in semiconductor physics refers to the process where donor impurities (n-type) are partially neutralized by acceptor impurities, resulting in a reduction of free charge carriers. This balance affects the effective carrier concentration, altering the electrical conductivity and overall behavior of the semiconductor material. Understanding compensation is crucial for tailoring semiconductor properties for specific electronic applications.

Understanding N-type Semiconductor Basics

N-type semiconductors are created by doping intrinsic silicon with donor impurities such as phosphorus or arsenic, which introduce free electrons as majority carriers. Compensation in N-type materials occurs when acceptor impurities counteract donor atoms, reducing the free electron concentration and altering the semiconductor's electrical properties. Understanding the balance between donor and acceptor impurities is crucial for optimizing conductivity and device performance in N-type semiconductors.

Compensation Mechanisms in N-type Materials

Compensation mechanisms in N-type materials primarily involve balancing donor and acceptor defect populations to regulate free electron concentration. Common compensation occurs through the introduction of acceptor-like defects such as vacancies or interstitials that trap free electrons, reducing conductivity. Optimizing these mechanisms enhances carrier mobility and stability in semiconductors like silicon and gallium nitride, crucial for electronic and optoelectronic device performance.

Influence of Doping on N-type Semiconductors

Doping N-type semiconductors with donor impurities introduces extra electrons, enhancing conductivity by increasing free charge carriers. Compensation occurs when acceptor impurities are unintentionally introduced, neutralizing donor electrons and reducing the net carrier concentration, thereby diminishing electrical performance. The balance between donor and acceptor dopants directly influences the semiconductor's conductivity, enabling precise control of electrical properties in N-type materials.

Key Differences: Pure N-type vs Compensated N-type

Pure N-type silicon contains only donor impurities, resulting in electrons as the majority charge carriers and minimal hole presence, leading to high electron mobility and conductivity. Compensated N-type silicon includes both donor and acceptor impurities, where acceptor atoms partially neutralize donor atoms, reducing the effective electron concentration and altering electrical properties. This compensation decreases carrier mobility and conductivity compared to pure N-type, affecting device performance in semiconductors.

Electrical Properties: Compensation Impact on N-type Conductivity

Compensation in N-type semiconductors significantly influences electrical properties by reducing free electron concentration, which directly affects conductivity. The presence of acceptor impurities or defects compensates donor electrons, leading to decreased carrier mobility and increased resistivity. Optimizing compensation levels is critical for tailoring N-type conductivity in semiconductor devices.

Applications of Compensated N-type Semiconductors

Compensated N-type semiconductors are widely applied in radiation detectors and photovoltaic devices where controlled electrical properties are crucial for performance optimization. By carefully adjusting donor and acceptor impurity concentrations, these materials achieve high resistivity and stability, essential for precision sensors and high-efficiency solar cells. Industrial applications benefit from compensated N-type semiconductors in producing components with tailored charge carrier lifetimes and reduced noise levels.

Challenges in Managing Compensation for N-type Devices

Managing compensation for N-type devices presents significant challenges due to the inherent variability in electron mobility and doping concentrations, which affect device performance consistency. Precise control over compensation levels is critical to minimize defects and optimize conductivity, yet discrepancies during fabrication lead to unpredictable electrical behavior. Advanced characterization techniques and adaptive compensation strategies are required to address these inconsistencies and enhance device reliability in semiconductor applications.

Future Trends in Compensation Engineering and N-type Materials

Future trends in compensation engineering emphasize integrating advanced N-type materials such as GaN and SiC for enhanced electronic device performance, offering superior efficiency and thermal stability. Emerging research explores novel doping techniques and heterostructures to optimize charge carrier mobility and reduce power loss in N-type semiconductors. Industry adoption of these innovations drives the development of high-performance power electronics and next-generation energy-efficient technologies.

Compensation Infographic

libterm.com

libterm.com