Incineration is a waste treatment process that involves burning organic materials at high temperatures to reduce volume and destroy hazardous substances. This method effectively decreases landfill use and can generate energy, making it a practical solution for waste management. Discover how incineration works and the benefits it can bring to your waste disposal strategies in the rest of the article.

Table of Comparison

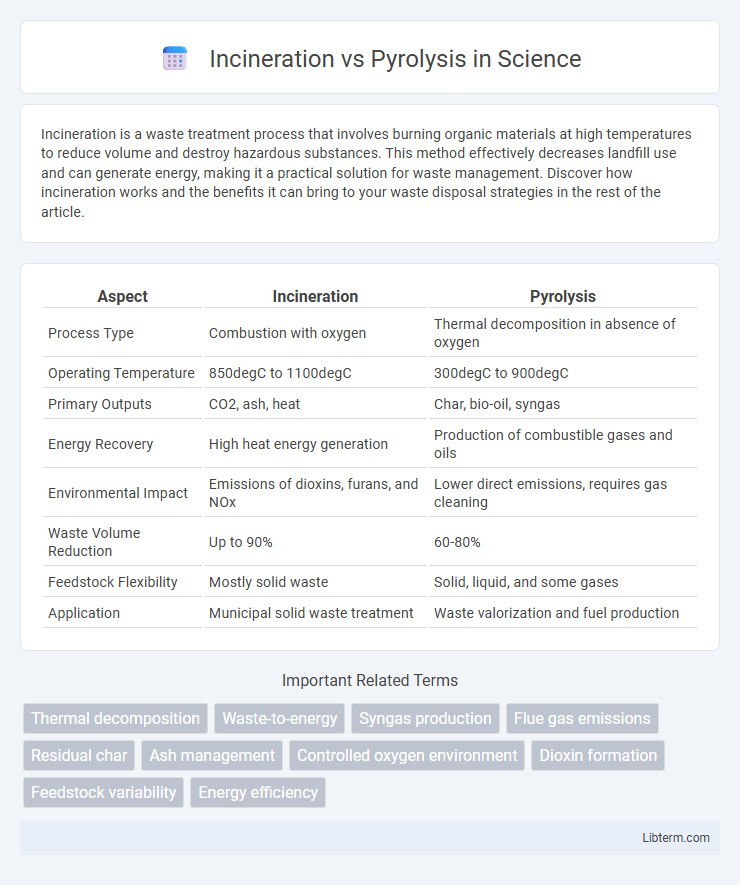

| Aspect | Incineration | Pyrolysis |

|---|---|---|

| Process Type | Combustion with oxygen | Thermal decomposition in absence of oxygen |

| Operating Temperature | 850degC to 1100degC | 300degC to 900degC |

| Primary Outputs | CO2, ash, heat | Char, bio-oil, syngas |

| Energy Recovery | High heat energy generation | Production of combustible gases and oils |

| Environmental Impact | Emissions of dioxins, furans, and NOx | Lower direct emissions, requires gas cleaning |

| Waste Volume Reduction | Up to 90% | 60-80% |

| Feedstock Flexibility | Mostly solid waste | Solid, liquid, and some gases |

| Application | Municipal solid waste treatment | Waste valorization and fuel production |

Introduction to Incineration and Pyrolysis

Incineration is a high-temperature waste treatment process that combusts organic materials to convert waste into ash, flue gas, and heat, effectively reducing waste volume and generating energy. Pyrolysis involves the thermal decomposition of organic materials at elevated temperatures in an oxygen-free environment, producing bio-oil, syngas, and char, which can be utilized as fuel or chemical feedstocks. Both technologies offer waste-to-energy solutions but differ significantly in operational conditions and byproduct composition.

How Incineration Works

Incineration works by burning waste at high temperatures, typically between 850degC and 1100degC, in the presence of oxygen, which converts organic materials into ash, flue gas, and heat. The heat generated can be harnessed to produce steam and electricity, making incineration a waste-to-energy process. This method effectively reduces waste volume by up to 90%, while emissions are controlled using advanced air pollution control systems to minimize environmental impact.

The Pyrolysis Process Explained

The pyrolysis process involves heating organic materials in an oxygen-free environment to decompose complex substances into simpler compounds, producing syngas, bio-oil, and char. This thermochemical conversion differs from incineration, which burns waste in the presence of oxygen, resulting primarily in ash, carbon dioxide, and water vapor. Pyrolysis enables energy recovery and material recycling with lower emissions and greater control over product outputs than traditional incineration methods.

Key Differences Between Incineration and Pyrolysis

Incineration is a combustion process that burns waste at high temperatures, producing ash, flue gases, and heat, whereas pyrolysis thermally decomposes organic materials in an oxygen-free environment, generating bio-oil, syngas, and char. Incineration primarily reduces waste volume and can generate electricity but emits pollutants like dioxins, while pyrolysis offers a cleaner alternative with greater recovery of valuable energy and fewer emissions. The temperature range for incineration typically exceeds 850degC, whereas pyrolysis operates between 300degC and 700degC, enabling distinct chemical reactions and product outcomes.

Environmental Impacts of Incineration

Incineration produces significant amounts of air pollutants, including dioxins, furans, and heavy metals, which contribute to environmental toxicity and health risks. The process generates ash containing hazardous residues that require careful disposal to prevent soil and water contamination. Despite energy recovery, incineration's greenhouse gas emissions and potential for toxic releases pose challenges for sustainable waste management.

Environmental Benefits of Pyrolysis

Pyrolysis offers significant environmental benefits over incineration by converting waste into valuable byproducts like biochar, oils, and syngas without releasing harmful dioxins and furans. The low-oxygen thermal decomposition process in pyrolysis reduces greenhouse gas emissions and minimizes air pollution compared to the high-temperature, oxygen-rich combustion in incineration. Furthermore, pyrolysis enables carbon sequestration through biochar application in soil, enhancing soil health and reducing overall carbon footprint.

Energy Recovery from Both Processes

Incineration produces energy by combusting waste at high temperatures, generating steam for electricity and heat but often releases significant emissions requiring treatment. Pyrolysis thermally decomposes organic materials in an oxygen-free environment, yielding bio-oil, syngas, and char, which can be used as fuels or feedstocks, offering higher energy recovery efficiency and lower emissions. Energy recovery from pyrolysis includes capturing combustible gases for power generation and converting liquid bio-oil into transportation fuels, making it a more versatile and environmentally friendly option compared to traditional incineration.

Emissions and Byproducts Comparison

Incineration produces higher emissions of nitrogen oxides, sulfur dioxide, and particulate matter due to the combustion of waste in the presence of oxygen, leading to the formation of toxic ash as a byproduct. Pyrolysis operates under oxygen-starved conditions, resulting in lower emissions of harmful gases and generating valuable byproducts such as bio-oil, syngas, and char, which can be utilized as fuel or soil amendments. Both technologies require emissions control systems, but pyrolysis tends to offer a cleaner environmental profile with fewer toxic residues compared to incineration.

Economic Considerations: Costs and Benefits

Incineration generally involves higher operating costs due to complex air pollution controls and fuel requirements but yields immediate energy recovery through electricity generation. Pyrolysis offers potential economic benefits by producing valuable byproducts such as bio-oil, syngas, and char, which can be sold as fuels or raw materials, enhancing revenue streams. Capital expenditures for pyrolysis plants tend to be higher, but lower emissions and byproduct commercialization can offset these expenses over time.

Future Trends and Innovations in Waste Treatment

Advancements in incineration technology are focusing on enhanced emission controls and energy recovery systems to meet stringent environmental regulations. Pyrolysis innovation emphasizes producing higher-value biochar, synthetic fuels, and reducing greenhouse gas emissions through optimized thermal decomposition processes. Integration of AI and real-time monitoring systems is driving efficiency and sustainability in both waste treatment methods.

Incineration Infographic

libterm.com

libterm.com