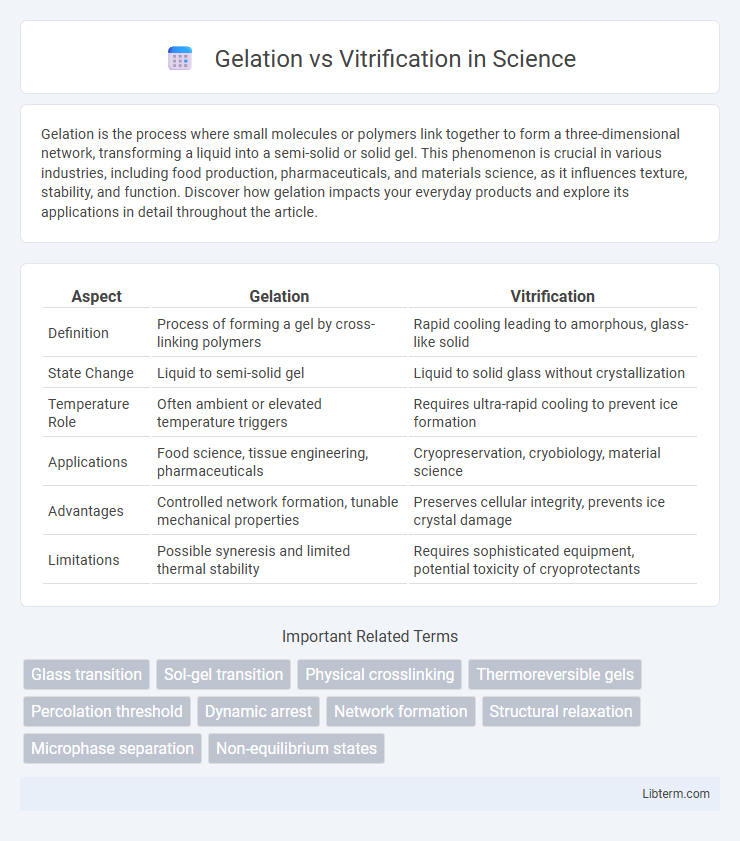

Gelation is the process where small molecules or polymers link together to form a three-dimensional network, transforming a liquid into a semi-solid or solid gel. This phenomenon is crucial in various industries, including food production, pharmaceuticals, and materials science, as it influences texture, stability, and function. Discover how gelation impacts your everyday products and explore its applications in detail throughout the article.

Table of Comparison

| Aspect | Gelation | Vitrification |

|---|---|---|

| Definition | Process of forming a gel by cross-linking polymers | Rapid cooling leading to amorphous, glass-like solid |

| State Change | Liquid to semi-solid gel | Liquid to solid glass without crystallization |

| Temperature Role | Often ambient or elevated temperature triggers | Requires ultra-rapid cooling to prevent ice formation |

| Applications | Food science, tissue engineering, pharmaceuticals | Cryopreservation, cryobiology, material science |

| Advantages | Controlled network formation, tunable mechanical properties | Preserves cellular integrity, prevents ice crystal damage |

| Limitations | Possible syneresis and limited thermal stability | Requires sophisticated equipment, potential toxicity of cryoprotectants |

Introduction to Gelation and Vitrification

Gelation is a process where a liquid transforms into a gel through the formation of a three-dimensional network, often involving polymer cross-linking or colloidal particle aggregation. Vitrification refers to the transition of a liquid into a glassy, non-crystalline solid state by rapid cooling that prevents crystallization. Both processes influence material properties such as viscosity, rigidity, and thermal stability, playing critical roles in fields like food science, cryopreservation, and materials engineering.

Defining Gelation: Key Processes and Outcomes

Gelation is the process where polymers or colloidal particles form a three-dimensional network resulting in a transition from a liquid to a gel state, characterized by increased viscosity and elasticity. This network formation occurs through physical or chemical crosslinking mechanisms, affecting material properties like rigidity and solvent retention. Gelation outcomes include enhanced structural stability and altered diffusion dynamics, distinct from vitrification, which involves an amorphous solidification without network formation.

Understanding Vitrification: Concepts and Mechanisms

Vitrification is a process where a liquid transforms into an amorphous solid without crystallization, preserving cellular structures by rapidly cooling biological samples to prevent ice formation. This method relies on high concentrations of cryoprotectants and ultra-rapid cooling rates, enabling cells or tissues to enter a glass-like state, which is critical in cryopreservation for maintaining viability. Understanding the mechanisms of vitrification involves studying the balance between cryoprotectant toxicity and cooling kinetics to optimize survival rates in applications like embryo freezing and organ preservation.

Molecular and Structural Differences

Gelation involves the formation of a three-dimensional network through physical or chemical crosslinking of polymer chains, resulting in a semi-solid state with interconnected molecular structures. Vitrification refers to the transition of a liquid into an amorphous glassy solid where molecular mobility is significantly reduced, and the material lacks long-range order but maintains a rigid, disordered structure. Structurally, gelation features an organized network of polymer junctions, whereas vitrification is characterized by molecular arrest without organized connectivity, impacting mechanical and thermal properties distinctly.

Thermodynamics of Gelation vs Vitrification

Gelation involves the formation of a polymer network through chemical or physical cross-linking, driven by thermodynamic phase separation and entropy reduction, resulting in a semi-solid gel state. Vitrification is the transition of a liquid into a glassy, amorphous solid without crystallization, characterized by a dramatic increase in viscosity and a kinetically frozen disorder state originating from thermodynamic supercooling. The thermodynamics of gelation emphasizes equilibrium phase behavior and network connectivity, whereas vitrification centers on nonequilibrium kinetic arrest and energy landscape trapping.

Common Applications in Science and Industry

Gelation is widely employed in biomedical engineering for developing hydrogels used in drug delivery systems and tissue scaffolding due to its controlled network formation. Vitrification finds extensive applications in cryopreservation of biological samples, such as embryos and stem cells, by preventing ice crystal formation and preserving cell viability. Both processes are critical in materials science for creating polymers and glass-like substances with tailored mechanical and thermal properties.

Comparing Mechanical Properties

Gelation exhibits lower mechanical strength and elasticity due to its network structure formed by physical cross-links, resulting in a softer and more flexible material. Vitrification results in a rigid, glass-like state with significantly higher mechanical stiffness and brittleness, owing to the immobilization of molecules in an amorphous solid. The mechanical modulus and fracture toughness are generally superior in vitrified materials compared to gels, impacting their applicability in load-bearing scenarios.

Advantages and Limitations of Each Process

Gelation offers advantages such as ease of processing and the ability to form uniform polymer networks at relatively low temperatures, making it suitable for biomedical and food applications. However, gelation can be limited by slower reaction times and potential sensitivity to environmental factors like pH and ionic strength, which may affect product stability. Vitrification provides superior thermal stability and resistance to molecular mobility, benefiting applications requiring long-term preservation, yet it often involves rapid cooling and higher energy input, which can introduce stresses and complexity in scale-up processes.

Factors Influencing Gelation and Vitrification

Factors influencing gelation include polymer concentration, temperature, pH, and cross-linking density, which determine the formation and strength of the gel network. Vitrification is primarily affected by cooling rate, solute concentration, and molecular mobility, which govern the transition of a solution into a glassy, amorphous state without crystallization. Both processes rely on controlling environmental conditions to achieve desired physical properties in materials such as hydrogels and cryopreserved biological samples.

Future Directions and Innovations

Future directions in gelation and vitrification emphasize developing hybrid materials that combine the mechanical strength of gels with the thermal stability of vitrified states. Innovations in nanoscale control and real-time monitoring techniques aim to enhance precision in manipulating phase transitions, enabling customized applications in biomedical engineering and materials science. Advances in computational modeling and machine learning also promise to accelerate the discovery of novel gelation and vitrification pathways, optimizing performance for next-generation technologies.

Gelation Infographic

libterm.com

libterm.com