Capacity defines the maximum amount something can hold, produce, or accommodate. Understanding capacity is crucial for optimizing space, resources, and productivity in various contexts like storage, manufacturing, or event planning. Explore the article to discover how mastering capacity can enhance your efficiency and decision-making.

Table of Comparison

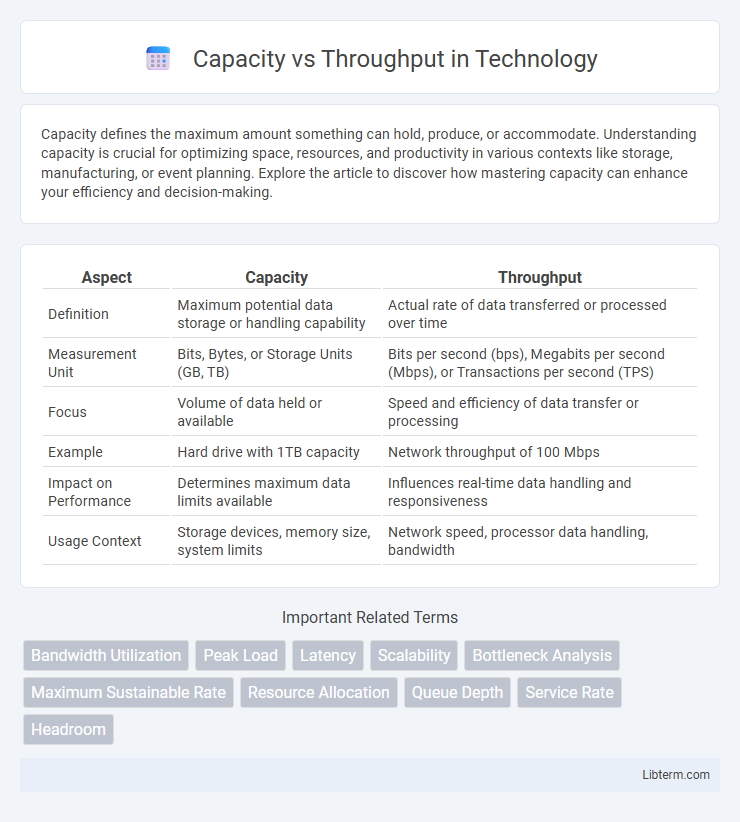

| Aspect | Capacity | Throughput |

|---|---|---|

| Definition | Maximum potential data storage or handling capability | Actual rate of data transferred or processed over time |

| Measurement Unit | Bits, Bytes, or Storage Units (GB, TB) | Bits per second (bps), Megabits per second (Mbps), or Transactions per second (TPS) |

| Focus | Volume of data held or available | Speed and efficiency of data transfer or processing |

| Example | Hard drive with 1TB capacity | Network throughput of 100 Mbps |

| Impact on Performance | Determines maximum data limits available | Influences real-time data handling and responsiveness |

| Usage Context | Storage devices, memory size, system limits | Network speed, processor data handling, bandwidth |

Understanding Capacity and Throughput

Capacity defines the maximum volume of work or data a system can handle within a given time frame, while throughput measures the actual amount processed or transmitted. Understanding capacity helps in planning resource allocation and scaling, whereas throughput provides insights into real-time performance and efficiency. Monitoring both metrics is essential for optimizing system operations and avoiding bottlenecks.

Key Differences Between Capacity and Throughput

Capacity refers to the maximum potential output a system or network can handle under ideal conditions, measured in units such as Mbps for data or units/hour for manufacturing. Throughput represents the actual achieved rate of successful data transmission or production, often lower than capacity due to factors like congestion, errors, or resource limitations. Key differences include capacity being a theoretical upper limit while throughput reflects real-world performance affected by operational constraints.

Measuring Capacity in Operations

Measuring capacity in operations involves quantifying the maximum output a process or system can achieve under ideal conditions, often expressed in units per hour or per shift. This measurement requires evaluating factors such as equipment capability, workforce availability, and process efficiency to determine the theoretical production limit. Understanding capacity enables businesses to plan resources effectively and identify bottlenecks that restrict throughput, which is the actual output realized over a period.

Defining Throughput in Business Context

Throughput in a business context refers to the rate at which a system or process produces finished goods or services over a specific period. It measures the actual output that successfully passes through various stages, directly impacting revenue generation and operational efficiency. Understanding throughput helps businesses optimize workflows, manage bottlenecks, and align production with customer demand to maximize profitability.

Factors Influencing Capacity

Capacity depends on factors such as bandwidth, signal quality, and network infrastructure, which determine the maximum data rate a system can support. Environmental conditions, including interference and physical obstructions, significantly impact signal strength and thus reduce effective capacity. Hardware limitations and protocol efficiency also play crucial roles in defining the theoretical and practical capacity of communication networks.

Factors Affecting Throughput

Throughput is primarily influenced by network congestion, hardware capabilities, protocol efficiency, and environmental conditions such as signal interference and distance in wireless networks. Unlike capacity, which denotes the maximum theoretical data rate, throughput reflects the actual data successfully transmitted over a network within a given time frame. Factors like packet loss, latency, error rates, and bandwidth availability directly impact throughput performance in real-world scenarios.

Capacity Planning Strategies

Capacity planning strategies involve forecasting future workload demands to ensure systems can handle peak throughput efficiently, minimizing bottlenecks and resource underutilization. Effective capacity planning uses historical data analysis, trend forecasting, and performance modeling to allocate resources dynamically, optimizing both system capacity and throughput. Balancing capacity with actual throughput requirements helps maintain system reliability, reduce latency, and improve overall operational performance.

Optimizing Throughput for Efficiency

Optimizing throughput involves maximizing the actual output of a system within its capacity constraints to ensure efficient resource utilization and process performance. By fine-tuning factors such as workflow design, bottleneck identification, and load balancing, throughput can be enhanced without necessarily increasing capacity. Effective throughput optimization improves operational efficiency, reduces waste, and accelerates delivery times, leading to higher overall productivity.

Balancing Capacity and Throughput

Balancing capacity and throughput involves optimizing resource allocation to maximize system efficiency while avoiding bottlenecks. Effective strategies include monitoring real-time data to adjust workloads dynamically and implementing scalable infrastructure to accommodate fluctuating demand. Achieving equilibrium ensures consistent performance, reduces latency, and enhances overall operational productivity.

Real-World Examples: Capacity vs Throughput

Data center capacity refers to the maximum volume of data and operations a system can handle, while throughput measures the actual data processed within a specific time frame. In telecommunications, a fiber optic cable may have a capacity of 40 Gbps but an actual throughput of 25 Gbps due to network congestion and protocol overhead. Manufacturing plants often have a production capacity of 1,000 units per day, yet throughput can drop to 800 units due to machine maintenance and workforce efficiency.

Capacity Infographic

libterm.com

libterm.com