Soft start technology reduces electrical stress and mechanical wear by gradually increasing voltage during motor startup, enhancing equipment lifespan and energy efficiency. This method is crucial for preventing sudden power surges and minimizing maintenance costs in industrial applications. Discover how implementing a soft start can benefit your operations by reading the full article.

Table of Comparison

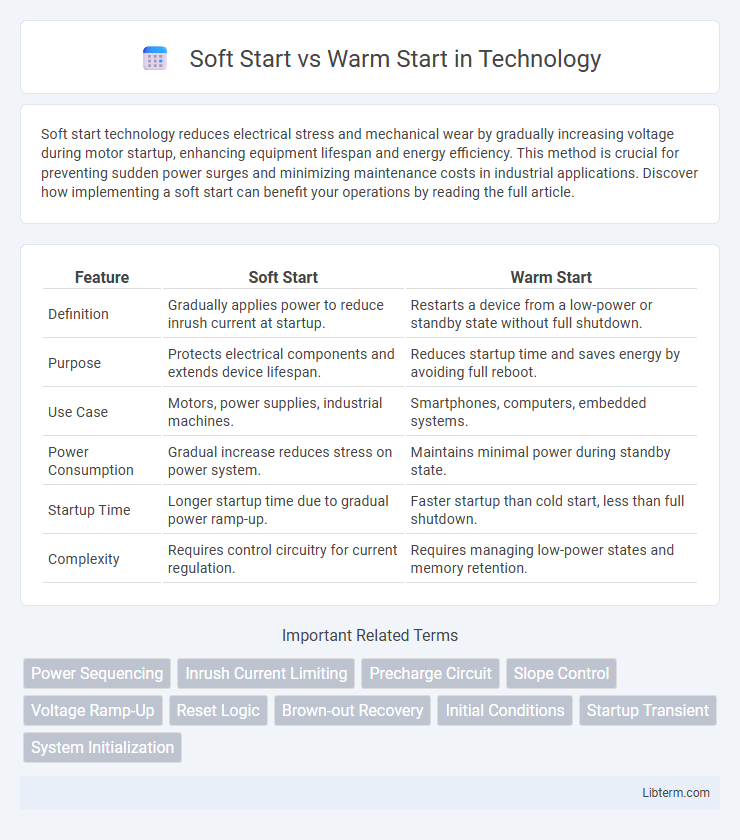

| Feature | Soft Start | Warm Start |

|---|---|---|

| Definition | Gradually applies power to reduce inrush current at startup. | Restarts a device from a low-power or standby state without full shutdown. |

| Purpose | Protects electrical components and extends device lifespan. | Reduces startup time and saves energy by avoiding full reboot. |

| Use Case | Motors, power supplies, industrial machines. | Smartphones, computers, embedded systems. |

| Power Consumption | Gradual increase reduces stress on power system. | Maintains minimal power during standby state. |

| Startup Time | Longer startup time due to gradual power ramp-up. | Faster startup than cold start, less than full shutdown. |

| Complexity | Requires control circuitry for current regulation. | Requires managing low-power states and memory retention. |

Introduction to Soft Start and Warm Start

Soft Start gradually powers a device by slowly increasing voltage, minimizing stress on electronic components and extending their lifespan during startup. Warm Start occurs when a device restarts without fully powering down, preserving certain operational states or memory to enable quicker resumption of function. Understanding these startup methods is essential for optimizing performance and protecting sensitive equipment in industrial and consumer electronics.

Defining Soft Start: Key Concepts

Soft start refers to a control method used to gradually increase the power or voltage supplied to electrical devices, minimizing inrush current and mechanical stress during startup. Key concepts include ramping up current or voltage smoothly, reducing thermal and electrical stress, and enhancing the longevity of motors and electronic components. This technique is essential for preventing abrupt electrical surges, improving energy efficiency, and ensuring reliable operation in industrial applications.

Understanding Warm Start: Essential Features

Warm start allows a machine or software to restart with prior operational data preserved, significantly reducing initialization time compared to a cold start while avoiding the complete reset of settings and processes. This method maintains active sessions, cached information, and system states, enabling faster resumption of tasks and minimizing downtime in complex systems such as databases, applications, and embedded devices. Understanding warm start's essential features helps optimize performance by balancing efficient resource use and operational continuity.

Differences Between Soft Start and Warm Start

Soft Start gradually increases the power supply voltage or current to electronic components to prevent inrush current and reduce stress on the system, enhancing longevity. Warm Start refers to restarting a device or system without a complete power down, retaining some operational states for a faster reboot. The key difference lies in Soft Start managing the initial power surge during startup, while Warm Start focuses on resuming operation from a partially active state.

Applications of Soft Start in Industry

Soft start technology is widely applied in industrial settings to reduce mechanical stress and electrical inrush current during motor startup, enhancing equipment longevity and energy efficiency. It is commonly used in conveyor systems, pumps, compressors, and HVAC units to ensure smoother acceleration and prevent damage to both the motor and connected machinery. Industries benefiting from soft start applications include manufacturing, oil and gas, water treatment, and material handling, where consistent and controlled motor startups are critical for operational stability.

Typical Use Cases for Warm Start

Warm start is typically used in machine learning scenarios where training continues from a previously saved model state, enabling faster convergence and resource efficiency compared to cold start methods. It is ideal for iterative training processes, transfer learning, and fine-tuning pre-trained models on new data without restarting from scratch. Applications include natural language processing, computer vision, and real-time system updates where minimizing downtime and computational load is critical.

Advantages of Soft Start Systems

Soft start systems provide gradual voltage ramp-up, reducing inrush current and mechanical stress on motors, which extends equipment lifespan and enhances safety. These systems improve energy efficiency by minimizing power surges and allow smoother operation during startup, reducing maintenance costs and downtime. Soft start technology also prevents voltage dips in electrical networks, ensuring stable power supply and protecting sensitive devices.

Benefits of Implementing Warm Start

Warm start reduces device stress by gradually applying voltage, enhancing longevity and reliability compared to the abrupt power surge during a soft start. This method minimizes inrush current, preventing damage to electrical components and lowering maintenance costs. Implementing warm start improves overall system stability and operational efficiency in sensitive electronics and industrial machinery.

Choosing Between Soft Start and Warm Start

Choosing between soft start and warm start depends on the desired control during power-up sequences and device longevity. Soft start gradually increases voltage or current to minimize inrush currents and protect components, ideal for sensitive electronics and power supplies. Warm start involves restarting a system with components already partially powered, suitable for applications requiring quick recovery without a full reset.

Conclusion: Which Start Method Is Best?

Soft start provides a gradual increase in power, reducing mechanical stress and extending equipment lifespan, making it ideal for sensitive or heavy machinery. Warm start offers faster startup times by maintaining certain system states, which benefits processes requiring quick resumption without a full reboot. The best start method depends on application needs: soft start suits durability and smooth operation, while warm start prioritizes speed and operational efficiency.

Soft Start Infographic

libterm.com

libterm.com