Vertical integration streamlines your supply chain by consolidating multiple production stages within a single company, reducing costs and enhancing control over quality. It improves efficiency through better coordination and faster decision-making, leading to a stronger competitive advantage in the market. Explore the rest of the article to understand how vertical integration can transform your business operations.

Table of Comparison

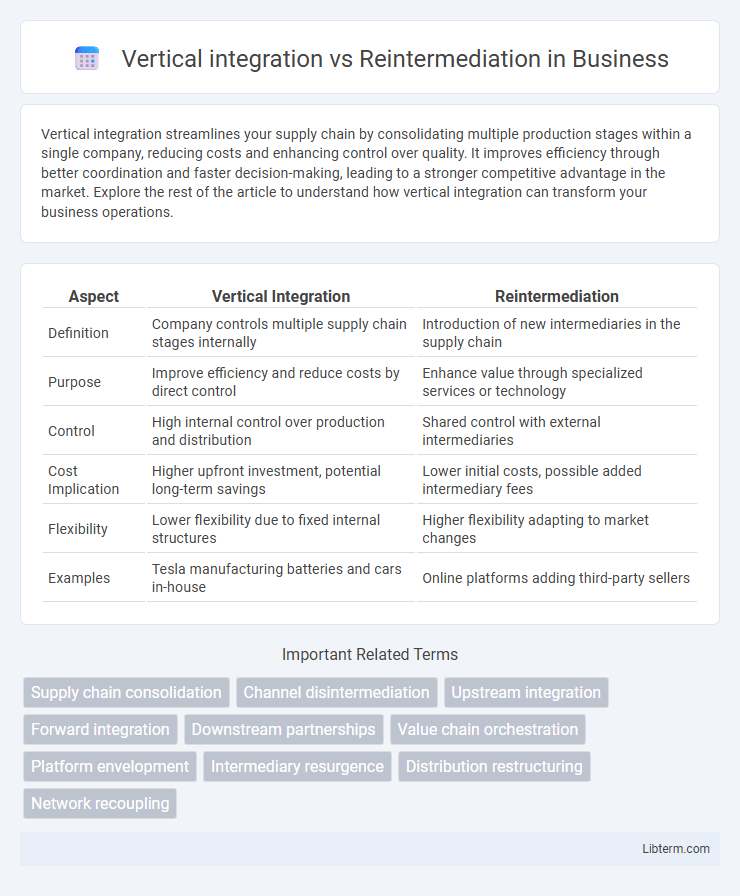

| Aspect | Vertical Integration | Reintermediation |

|---|---|---|

| Definition | Company controls multiple supply chain stages internally | Introduction of new intermediaries in the supply chain |

| Purpose | Improve efficiency and reduce costs by direct control | Enhance value through specialized services or technology |

| Control | High internal control over production and distribution | Shared control with external intermediaries |

| Cost Implication | Higher upfront investment, potential long-term savings | Lower initial costs, possible added intermediary fees |

| Flexibility | Lower flexibility due to fixed internal structures | Higher flexibility adapting to market changes |

| Examples | Tesla manufacturing batteries and cars in-house | Online platforms adding third-party sellers |

Introduction to Vertical Integration and Reintermediation

Vertical integration involves a company expanding its operations by acquiring or merging with businesses at different stages of the supply chain to increase control and reduce costs. Reintermediation refers to the process where new intermediaries are introduced between producers and consumers, often driven by digital platforms enhancing distribution channels. Both strategies reshape market dynamics by altering traditional value chains and influencing competitive advantages.

Defining Vertical Integration: Concepts and Examples

Vertical integration refers to a company's strategic control over multiple stages of its supply chain, from raw material sourcing to manufacturing and distribution, enhancing efficiency and reducing costs. For example, Tesla manufactures batteries and electric vehicles in-house, avoiding reliance on external suppliers, which exemplifies forward and backward integration. This approach contrasts with reintermediation, where new intermediaries are introduced to optimize or disrupt traditional supply chains.

Understanding Reintermediation: Key Principles

Reintermediation involves reintroducing intermediaries into supply chains or markets to enhance efficiency, customer service, and value delivery. Key principles include leveraging digital platforms to create new distribution channels, optimizing transaction costs, and improving access to market information. Understanding these concepts helps businesses balance control and specialization while adapting to evolving market dynamics and consumer demands.

Historical Evolution of Vertical Integration and Reintermediation

Vertical integration historically emerged as firms sought control over supply chains to reduce costs and enhance efficiency, exemplified by early 20th-century industrial giants like Carnegie Steel and Ford Motor Company. Reintermediation gained prominence in the digital era when businesses reintroduced intermediaries to leverage specialized expertise and technology, especially visible in e-commerce platforms integrating third-party logistics and payment systems. The contrasting evolution highlights vertical integration's focus on internal consolidation versus reintermediation's strategic reintroduction of specialized external partners to optimize value chains.

Drivers Behind Vertical Integration

The primary drivers behind vertical integration include the desire to reduce costs, increase control over the supply chain, and improve coordination between production stages. Companies pursue vertical integration to enhance operational efficiency by internalizing processes that were previously outsourced, thus minimizing transaction costs and dependency on third parties. Market dynamics such as the need for better quality control, faster time-to-market, and protection of proprietary technology also strongly motivate firms to integrate vertically.

Motivations for Reintermediation in Modern Markets

Reintermediation occurs as companies seek to reintroduce intermediaries to enhance customer experience, optimize supply chain efficiency, and leverage specialized expertise in modern markets. Motivations include addressing technological gaps, improving transaction security, and offering personalized services through data analytics platforms. This strategic shift often counters vertical integration by enabling businesses to remain agile and responsive to evolving consumer demands.

Advantages and Challenges of Vertical Integration

Vertical integration enhances control over the supply chain, reduces costs by eliminating intermediaries, and improves product quality through direct oversight. It also enables faster decision-making and greater market power, supporting differentiation and competitive advantage. Challenges include substantial capital investment, increased operational complexity, and reduced flexibility in adapting to market changes or technological shifts.

Benefits and Risks of Reintermediation

Reintermediation introduces new intermediaries in the supply chain, enhancing customer experience through specialized services and personalized support, while often improving market reach and operational efficiency. However, risks include increased transaction costs, potential conflicts of interest, and reduced direct control over customer relationships. Balancing these benefits and risks requires strategic management to ensure reintermediation aligns with overall business objectives and market dynamics.

Case Studies: Industry Comparisons

Vertical integration in the automotive industry exemplifies efficient supply chain consolidation, as seen in Tesla's control over battery production and vehicle assembly, enhancing quality and cost management. In contrast, reintermediation in the retail sector is illustrated by Amazon's expansion of third-party marketplaces, leveraging intermediaries to increase product diversity and customer reach. Comparative analysis reveals vertical integration favors industries with high capital investments and complex manufacturing, while reintermediation thrives in dynamic markets prioritizing flexibility and broad distribution networks.

Future Trends: Vertical Integration vs Reintermediation

Future trends indicate Vertical Integration will increasingly leverage advanced technologies like IoT and AI to streamline supply chains and enhance control over production processes. Reintermediation is expected to grow through digital platforms that reintroduce specialized intermediaries, facilitating personalized customer experiences and efficient market access. Both strategies will evolve as businesses balance operational efficiency with the need for agility in dynamic market conditions.

Vertical integration Infographic

libterm.com

libterm.com