Contracting involves creating legally binding agreements that outline the responsibilities and expectations between parties, ensuring clarity and protection for all involved. Effective contracting minimizes risks and promotes smooth project execution, whether in construction, services, or business partnerships. Explore the rest of this article to understand how your contracting strategies can optimize outcomes and safeguard your interests.

Table of Comparison

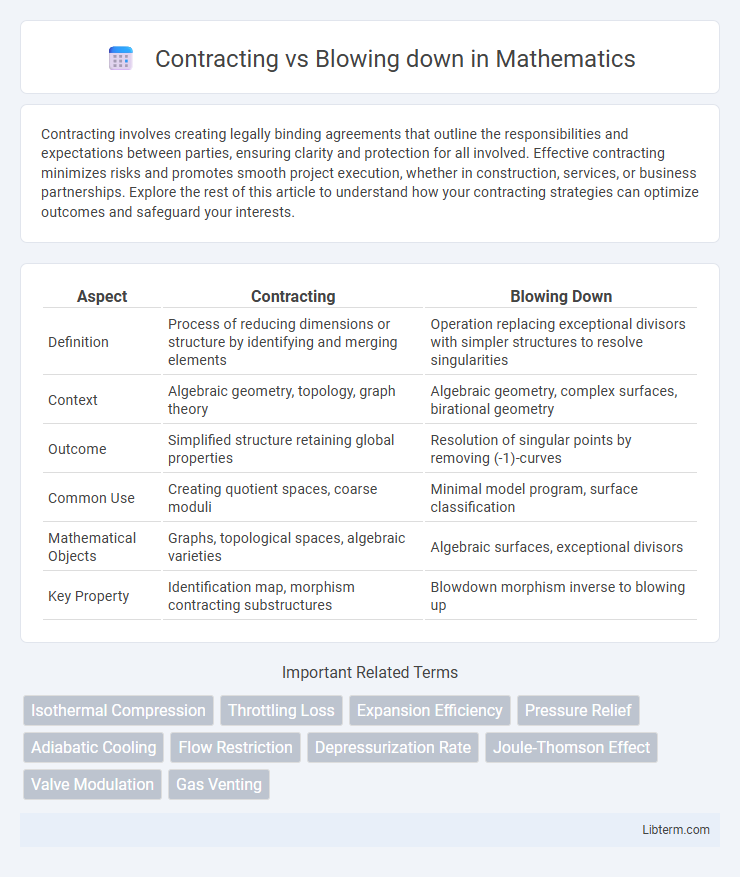

| Aspect | Contracting | Blowing Down |

|---|---|---|

| Definition | Process of reducing dimensions or structure by identifying and merging elements | Operation replacing exceptional divisors with simpler structures to resolve singularities |

| Context | Algebraic geometry, topology, graph theory | Algebraic geometry, complex surfaces, birational geometry |

| Outcome | Simplified structure retaining global properties | Resolution of singular points by removing (-1)-curves |

| Common Use | Creating quotient spaces, coarse moduli | Minimal model program, surface classification |

| Mathematical Objects | Graphs, topological spaces, algebraic varieties | Algebraic surfaces, exceptional divisors |

| Key Property | Identification map, morphism contracting substructures | Blowdown morphism inverse to blowing up |

Understanding Contracting and Blowing Down

Contracting refers to the deliberate process of reducing operational pressure in a controlled manner to maintain system integrity and safety, commonly applied in pipelines and pressure vessels. Blowing down involves rapidly releasing pressure or gas to protect equipment from overpressure or to remove contaminants, often seen in industrial plants and gas processing systems. Understanding the distinct purposes and methods of contracting and blowing down is essential for optimizing maintenance routines and ensuring compliance with safety standards.

Key Differences Between Contracting and Blowing Down

Contracting involves the controlled reduction of equipment volume or pressure through planned shutdowns, while blowing down refers to the rapid release of pressure or gases to ensure safety or maintenance. Contracting typically requires detailed scheduling and preparation to prevent operational disruptions, whereas blowing down is often an emergency or routine safety procedure to quickly relieve pressure. The primary difference lies in contracting's focus on systematic reduction versus blowing down's emphasis on immediate pressure release for protection and equipment integrity.

Processes Involved in Contracting

Contracting in industrial processes involves the deliberate reduction of volume or size, often achieved through mechanical compression, chemical reactions, or thermal contraction, to enhance material density or structural integrity. This process requires precise control of parameters such as pressure, temperature, and time to ensure the desired outcome without compromising material properties. In contrast, blowing down focuses on the removal or expulsion of fluids, gases, or impurities through pressure release or flushing to maintain system safety and efficiency.

Processes Involved in Blowing Down

Blowing down involves the controlled release of water, steam, or impurities from boilers and vessels to reduce pressure and remove sediment buildup, ensuring efficient operation and safety. The process requires precise valve operation to manage the flow rate and prevent thermal shock, often using bottom and surface blowdown valves strategically placed in the system. Effective blowing down minimizes corrosion, scaling, and potential damage, extending equipment lifespan and maintaining optimal heat transfer performance.

Advantages of Contracting in Industrial Applications

Contracting in industrial applications offers advantages such as cost efficiency through reduced labor and equipment expenses compared to blowing down. It also enhances precision in project timelines and resource management, minimizing downtime and improving operational continuity. By leveraging specialized contracting firms, industries benefit from expertise and compliance with safety and regulatory standards, leading to higher quality outcomes.

Benefits of Blowing Down for System Efficiency

Blowing down enhances system efficiency by removing accumulated impurities and sediment from boilers or pipelines, which prevents corrosion and scaling that degrade heat transfer and operational performance. Regular blowdown maintains optimal water chemistry, reducing energy consumption and extending equipment lifespan by ensuring consistent pressure and temperature control. This proactive maintenance approach minimizes unplanned downtime and costly repairs, leading to improved overall system reliability and cost savings.

Cost Comparisons: Contracting vs Blowing Down

Contracting typically incurs higher upfront costs due to professional service fees and comprehensive project management expenses, while blowing down involves lower immediate costs but may lead to increased maintenance and operational expenses over time. Blowing down requires ongoing labor and equipment usage, which can add to cumulative costs, whereas contracting can offer cost predictability through fixed bidding structures. Evaluating total lifecycle costs reveals that contracting may be more cost-effective for complex projects, whereas blowing down suits simpler, routine operations with minimal budget constraints.

Common Industries Using Each Method

Contracting is predominantly utilized in construction, manufacturing, and engineering industries where precise control of mechanical systems and equipment assembly is crucial. Blowing down finds frequent application in power generation, chemical processing, and oil refining sectors to maintain boiler and pressure vessel integrity by removing sediment and impurities. Both methods are essential for operational safety and efficiency across heavy industrial environments.

Environmental Impact: Contracting vs Blowing Down

Contracting in industrial systems typically reduces energy consumption and minimizes emissions by optimizing existing equipment, leading to a lower environmental footprint compared to blowing down. Blowing down involves releasing pressurized fluids or gases, often resulting in significant waste and increased emissions of pollutants or greenhouse gases. Prioritizing contracting helps industries comply with environmental regulations and supports sustainability goals by reducing resource waste and pollution.

Choosing the Right Approach for Your Operation

Selecting the ideal method between contracting and blowing down hinges on the specific needs of your operation, such as efficiency, cost, and safety requirements. Contracting offers controlled, strategic reductions aligned with maintenance schedules, whereas blowing down provides rapid pressure relief or cleanliness in pipelines and vessels. Evaluating factors like downtime tolerance, regulatory compliance, and resource availability ensures the optimal approach for operational success.

Contracting Infographic

libterm.com

libterm.com