Blowing down refers to the collapse of trees due to strong winds, often causing significant damage to forests and landscapes. This phenomenon impacts soil stability, disrupts ecosystems, and increases the risk of wildfires by accumulating deadwood. Discover how blowing down affects your environment and what measures can help mitigate its consequences in the following article.

Table of Comparison

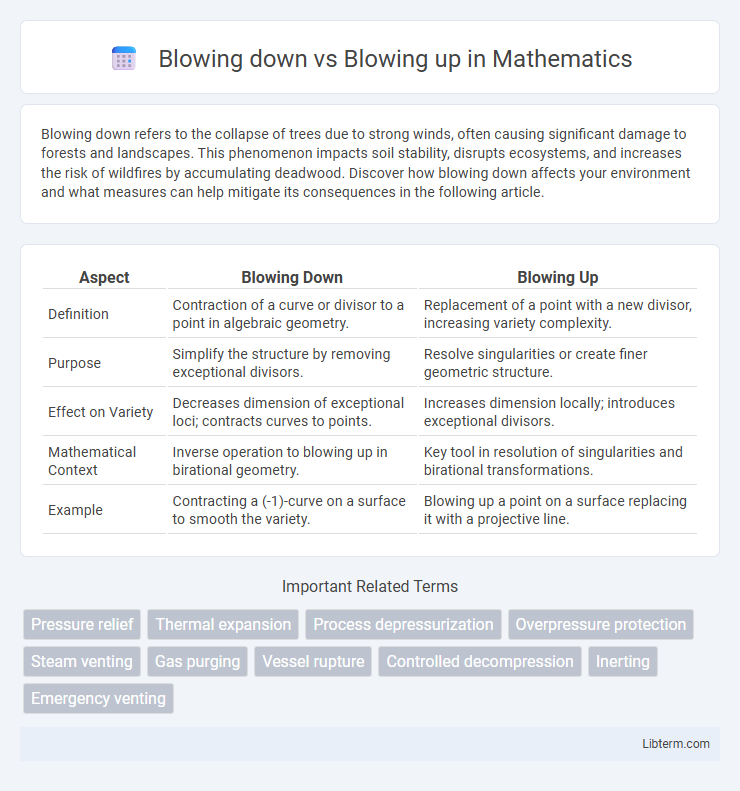

| Aspect | Blowing Down | Blowing Up |

|---|---|---|

| Definition | Contraction of a curve or divisor to a point in algebraic geometry. | Replacement of a point with a new divisor, increasing variety complexity. |

| Purpose | Simplify the structure by removing exceptional divisors. | Resolve singularities or create finer geometric structure. |

| Effect on Variety | Decreases dimension of exceptional loci; contracts curves to points. | Increases dimension locally; introduces exceptional divisors. |

| Mathematical Context | Inverse operation to blowing up in birational geometry. | Key tool in resolution of singularities and birational transformations. |

| Example | Contracting a (-1)-curve on a surface to smooth the variety. | Blowing up a point on a surface replacing it with a projective line. |

Introduction to Blowdown and Blowup Processes

Blowdown and blowup processes are crucial in industrial operations for managing pressure and ensuring safety. Blowdown involves controlled release of pressure or fluids to reduce system pressure, often used to remove contaminants or relieve excess pressure in boilers and pipelines. Blowup refers to the rapid and often uncontrolled expansion of gases or fluids, typically resulting in equipment failure or explosion, highlighting the importance of monitoring and maintenance protocols.

Definitions: What is Blowing Down? What is Blowing Up?

Blowing down refers to the controlled lowering or removal of equipment, structures, or pressure in industrial processes to ensure safety and prevent accidents. Blowing up describes a sudden, often explosive increase in pressure or volume, leading to potential equipment failure or hazardous situations. Understanding these terms is critical in fields like oil and gas, chemical engineering, and safety management to mitigate risks effectively.

Key Differences Between Blowing Down and Blowing Up

Blowing down involves the controlled release of pressure or gas from a system to reduce internal pressure, typically used in equipment like boilers or pipelines, while blowing up refers to an uncontrolled explosion causing rapid expansion and destruction. Key differences include the intent and outcome: blowing down is a safety procedure to prevent damage, whereas blowing up results from failure or hazardous conditions leading to catastrophic consequences. Blowing down is a preventive maintenance action, whereas blowing up is an accidental event often associated with equipment failure or improper handling of volatile substances.

Applications of Blowdown in Industry

Blowdown in industrial applications primarily refers to the controlled removal of impurities and sediments from boilers, pressure vessels, and cooling towers to maintain efficiency and safety. It is essential in power plants and manufacturing facilities to prevent scale buildup and corrosion, thereby prolonging equipment life and reducing maintenance costs. Proper blowdown procedures contribute to environmental compliance by minimizing the release of contaminants into wastewater streams.

Applications of Blowup in Engineering and Science

Blowup in engineering and science refers to the phenomenon where a variable, such as pressure or temperature, rapidly increases to an extreme value in finite time, often indicating system failure or critical transitions. Common applications include predicting rupture in pressure vessels, modeling thermal runaway in chemical reactors, and analyzing structural collapses under dynamic loads. Understanding blowup behavior helps design safer systems, optimize control strategies, and prevent catastrophic failures in industrial processes.

Safety Considerations: Blowing Down vs Blowing Up

Blowing down involves controlled venting of pressure from equipment to safely reduce operational pressure, minimizing risks of mechanical failure and ensuring personnel safety. Blowing up, often referring to unintentional explosions or rapid pressure increases, poses significant hazards including equipment damage, fire, and severe injury or fatality. Implementing stringent safety protocols, regular maintenance, and proper pressure relief systems are critical in preventing the dangers associated with both blowing down and blowing up scenarios.

Environmental Impacts of Blowdown and Blowup

Blowdown releases large volumes of contaminated water and chemicals, contributing to soil and water pollution with hazardous substances such as hydrocarbons and heavy metals. Blowup events often involve explosive releases of gases and particulates that can cause air pollution, including the dispersion of volatile organic compounds (VOCs) and greenhouse gases. Both processes pose significant environmental risks, requiring stringent monitoring and mitigation to minimize contamination and atmospheric emissions.

Efficiency and Cost Comparisons

Blowing down involves controlled removal of impurities from boilers, enhancing operational efficiency by preventing scale and corrosion, while blowing up refers to emergency pressure release, which is costly due to downtime and potential equipment damage. Efficiency gains from regular blowing down reduce fuel consumption and maintenance costs, whereas blowing up incidents result in higher repair expenses and lost production. Implementing optimized blowing down schedules minimizes overall operational costs compared to the reactive expenses caused by blowing up events.

Technological Innovations in Blowdown and Blowup

Technological innovations in blowdown systems have advanced with smart sensors and automated control to optimize pressure release and minimize environmental impact, enhancing safety and operational efficiency. Blowup technology has evolved through improved explosive materials and precision detonation techniques, enabling controlled demolition and industrial fracturing with reduced collateral damage. Integration of IoT and AI in both blowdown and blowup processes ensures real-time monitoring and adaptive response, revolutionizing traditional methods.

Conclusion: Choosing Between Blowing Down and Blowing Up

Blowing down efficiently removes pressure by releasing steam slowly, minimizing risk in controlled environments, while blowing up rapidly depressurizes systems but increases the potential for damage or hazards. The choice between blowing down and blowing up depends on system design, safety protocols, and operational priorities such as minimizing downtime or ensuring maximum safety. Careful evaluation of pressure vessel specifications and emergency response plans is essential for selecting the appropriate pressure relief method.

Blowing down Infographic

libterm.com

libterm.com