Compact designs maximize functionality while minimizing space, making them ideal for modern living and efficient work environments. Their streamlined structure ensures versatility without sacrificing performance or style. Explore the full article to discover how compact solutions can enhance your daily life.

Table of Comparison

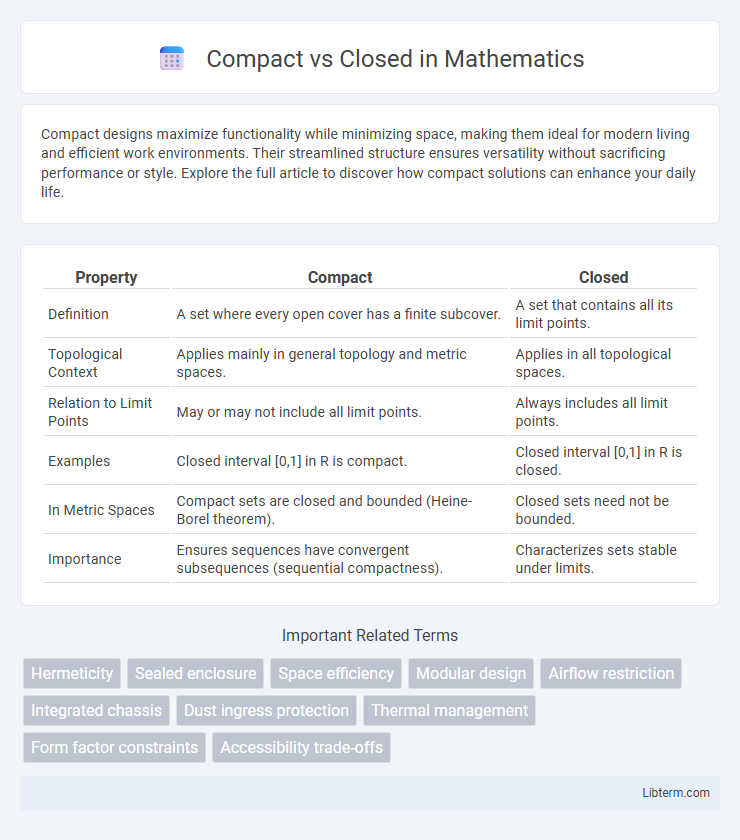

| Property | Compact | Closed |

|---|---|---|

| Definition | A set where every open cover has a finite subcover. | A set that contains all its limit points. |

| Topological Context | Applies mainly in general topology and metric spaces. | Applies in all topological spaces. |

| Relation to Limit Points | May or may not include all limit points. | Always includes all limit points. |

| Examples | Closed interval [0,1] in R is compact. | Closed interval [0,1] in R is closed. |

| In Metric Spaces | Compact sets are closed and bounded (Heine-Borel theorem). | Closed sets need not be bounded. |

| Importance | Ensures sequences have convergent subsequences (sequential compactness). | Characterizes sets stable under limits. |

Introduction to Compact vs Closed Designs

Compact designs emphasize space efficiency by minimizing size while maintaining essential functionality, ideal for applications with limited room. Closed designs prioritize complete enclosure, protecting components from external elements such as dust, moisture, and physical impact. Choosing between compact and closed designs depends on the balance between spatial constraints and environmental protection requirements.

Key Differences Between Compact and Closed Systems

Compact systems are designed for space efficiency, integrating components into a smaller footprint and often prioritizing portability and ease of installation. Closed systems feature airtight or sealed environments to prevent contamination and maintain controlled conditions, commonly used in processes requiring sterile or protected atmospheres. The key differences lie in compact systems emphasizing size reduction and convenience, whereas closed systems focus on isolation and environmental control for product integrity.

Advantages of Compact Systems

Compact systems offer significant space-saving advantages by integrating all components into a streamlined design, making them ideal for environments with limited room. They facilitate faster installation and easier maintenance due to their pre-assembled nature, reducing downtime and labor costs. Enhanced energy efficiency and improved performance consistency are often observed in compact systems thanks to optimized internal layouts and advanced materials.

Benefits of Closed Systems

Closed systems enhance hygiene by preventing external contaminants from entering, which is crucial in sterile environments like biotechnology and pharmaceuticals. They reduce the risk of cross-contamination, ensuring product purity and consistent quality during manufacturing or storage. These systems also improve operational efficiency by minimizing exposure to environmental variables, leading to lower maintenance costs and extended equipment lifespan.

Space Efficiency: Compact vs Closed

Compact designs maximize space efficiency by minimizing gaps and overlapping functional elements, making them ideal for environments with limited room. Closed configurations provide enhanced protection by enclosing components, often sacrificing some spatial economy for security and durability. Choosing between compact and closed models depends on balancing the need for efficient use of space against the requirement for environmental shielding.

Performance Comparison

Compact data structures optimize memory usage by minimizing redundancy, leading to faster cache access and reduced latency compared to closed structures that store data in fixed, predefined formats. Closed data structures, while easier to implement and manage, often suffer from slower performance due to increased memory overhead and less efficient cache utilization. Benchmark tests reveal that compact formats typically outperform closed formats in both read and write operations, especially in environments with limited resources or large-scale data processing.

Maintenance and Durability

Compact cabinets typically require less maintenance due to their dense material composition, which resists moisture, scratches, and stains better than closed cabinets made from traditional wood or particleboard. The durability of compact cabinets is enhanced by their solid, homogeneous panels, providing long-lasting structural integrity and reducing the need for frequent repairs or replacements. Closed cabinets often demand more upkeep to address potential warping, chipping, or surface wear, especially in high-moisture environments.

Cost Considerations

Compact furniture typically offers lower upfront costs due to its minimalist design and use of fewer materials, making it a budget-friendly option for small spaces. Closed furniture, with its enclosed storage and often more complex construction, tends to have higher manufacturing and material expenses, which can increase the overall price. Evaluating long-term durability and customization options is essential when considering the cost-effectiveness of compact versus closed furniture solutions.

Ideal Use Cases for Each System

Compact systems excel in environments requiring space-saving designs, such as small offices, mobile workstations, and minimalistic living areas, due to their streamlined and efficient form factor. Closed systems are ideal for secure and controlled settings like data centers, industrial automation, and sensitive research labs, offering enhanced protection from dust, moisture, and unauthorized access. Selecting between compact and closed systems depends on balancing space constraints with the need for durability and security.

Final Verdict: Choosing the Right System

Choosing between compact and closed systems depends on specific application requirements, with compact systems offering space efficiency and ease of integration, while closed systems provide superior contamination control and safety. Factors such as operational environment, maintenance needs, and regulatory compliance play critical roles in the decision-making process. Evaluating these parameters ensures selection of a system that maximizes performance and longevity in the targeted industrial context.

Compact Infographic

libterm.com

libterm.com